Method for preparing semiconductor photocatalyst ZnGa2O4 by solvothermal method and semiconductor photocatalyst ZnGa2O4

A technology of photocatalyst and solvothermal method, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult product purification, complex process, and product performance impact. Uniformity, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

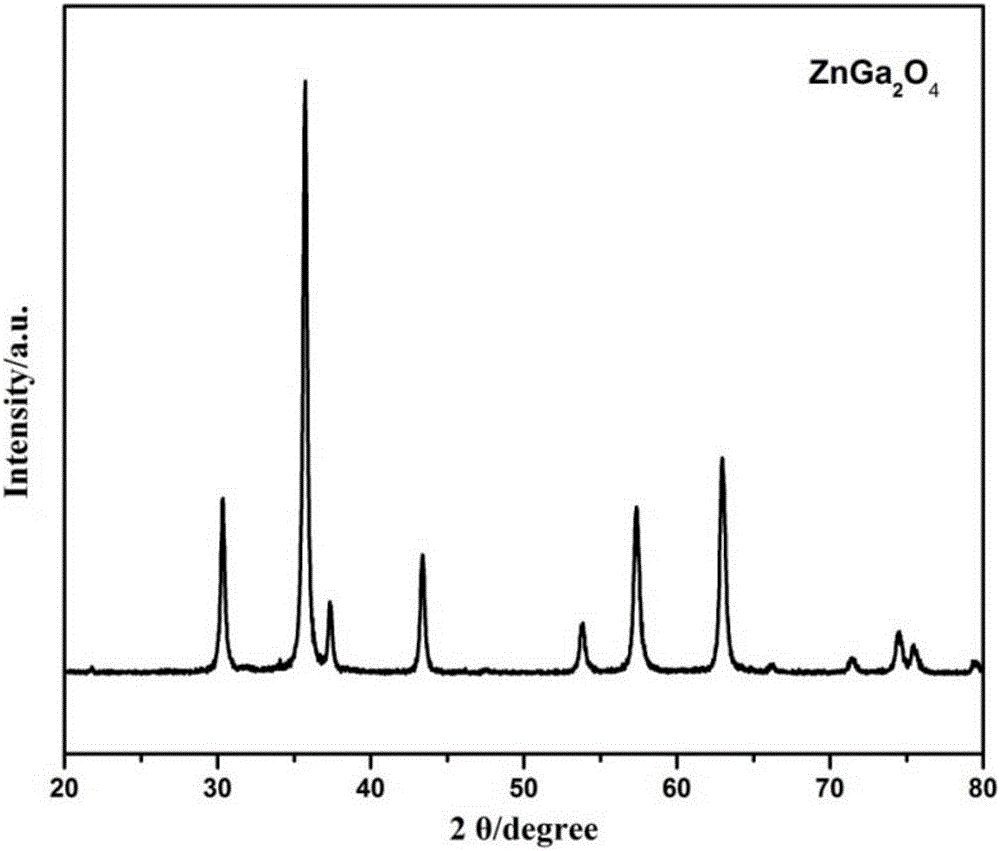

[0022] A ZnGa 2 o 4 The preparation method of semiconductor photocatalyst comprises the following steps:

[0023] Step A, add 30-40ml of deionized water to the polytetrafluoroethylene liner, and add 1.5-2.5mmol of gallium chloride (GaCl 3 ) and 1.5-2.5mmol ethylenediaminetetraacetic acid (EDTA), magnetically stirred for 5min; after dissolving, slowly add 11-13mmol sodium hydroxide (NaOH), when the pH value of the solution was 6, the solution changed from colorless to Milky white; continue to stir for 10 minutes, then seal the polytetrafluoroethylene liner into a stainless steel mold, start heating from room temperature under airtight conditions and heat the reaction at 150-200°C for 7-10 hours; naturally cool to room temperature after the reaction, and pass the product through distilled water , washed with absolute ethanol, dried in vacuum at 60°C for 4-6h to obtain a white powder; then put into a tube furnace, and calcined at 600-900°C for 1-3h in an air atmosphere to obtai...

Embodiment 1

[0030] A semiconductor photocatalyst ZnGa 2 o 4 The preparation method comprises the following steps:

[0031] Step A, add 36ml of deionized water to the polytetrafluoroethylene liner, add 2mmol of gallium chloride (GaCl 3 ) and 2mmol ethylenediaminetetraacetic acid (EDTA), magnetically stirred for 5min; after dissolving, slowly added 12.5mmol of sodium hydroxide (NaOH), the solution changed from colorless to milky white; continued to stir for 10min, and then put the polytetrafluoroethylene The liner is sealed into a stainless steel mold, heated from room temperature under airtight conditions and heated at 160°C for 8 hours; after the reaction, it is naturally cooled to room temperature, the product is washed with distilled water and absolute ethanol, and dried in vacuum at 60°C for 4-6 hours to obtain a white powder; Then put it into a tube furnace, and calcined at 700°C for 2h in the air atmosphere to obtain gallium oxide (Ga 2 o 3 )White powder;

[0032] Step B, add 34...

Embodiment 2

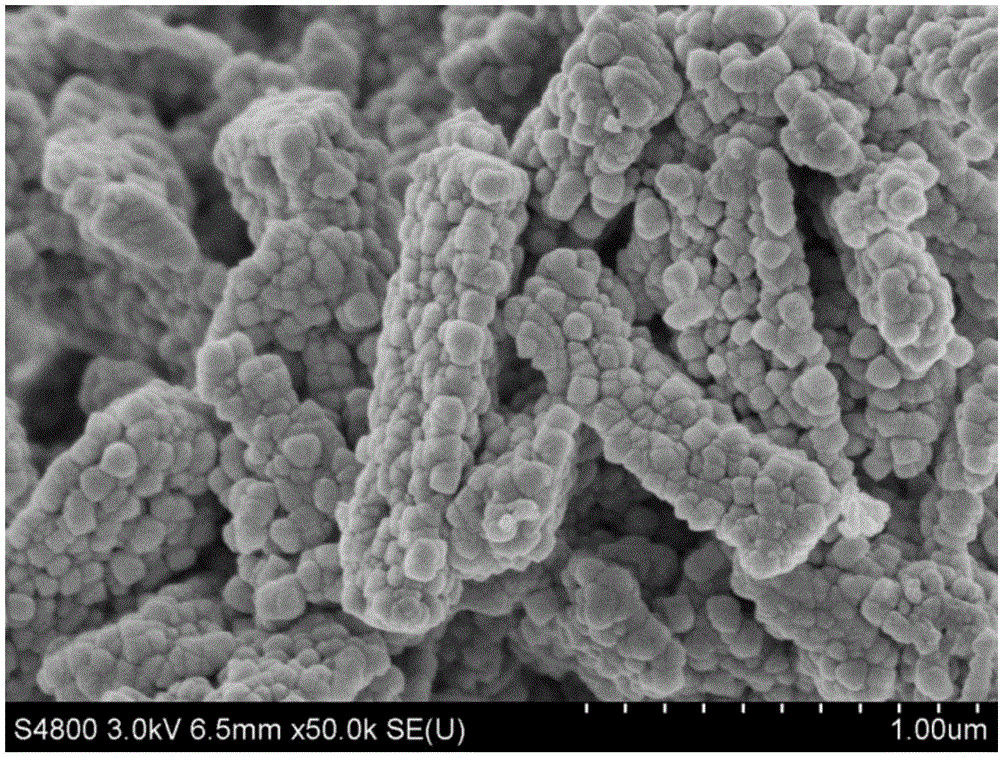

[0035] Change the amount of polyethylene glycol-200 (PEG-200) into 0.0ml in Step B in Example 1, and other conditions remain unchanged, and the resulting product is ZnGa 2 o 4 , compared with Example 1, the product has inhomogeneous size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com