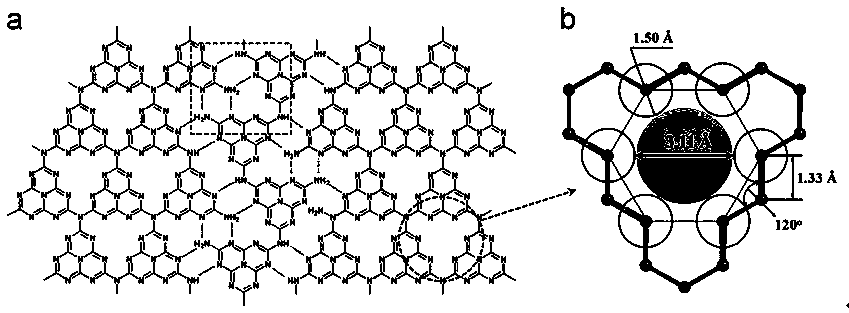

Preparation Method of Polyvinyl Alcohol/Graphite Phase Carbon Nitride Pervaporation Hybrid Membrane

A graphite phase carbon nitride, polyvinyl alcohol technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane and other directions, can solve the problems of reducing membrane separation performance, reducing membrane selectivity, poor compatibility, etc., to promote The effect of efficient large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

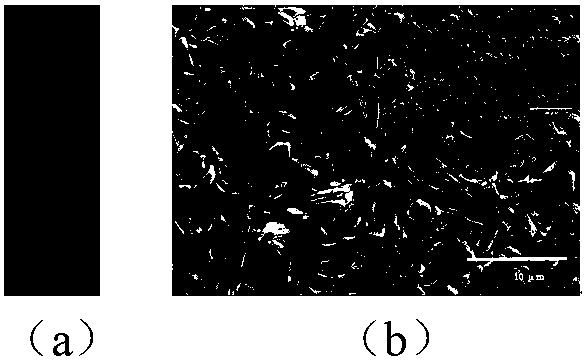

Embodiment 1

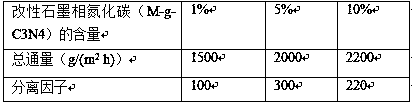

[0022] Example 1: Take 0.5g, 2.5g, and 5g of M-g-C3N4 powder and disperse them into 49.5mL, 47.5mL, and 45mL of deionized water, respectively, and prepare suspensions with a mass fraction of 1%, 5%, and 10%. 30W Ultrasonic treatment for 30 minutes; then add a certain mass of PVA and succinic acid so that the mass fractions of PVA and succinic acid are 10% and 2% respectively; stir at 1200 r / min at 80°C for 6 hours, and then vacuum degassing for 4 hours After standing still for 24 hours, the casting solution with different M-g-C3N4 content was obtained; the obtained casting solution was scraped on the bottom membrane of PAN ultrafiltration membrane to make a wet film with a thickness of 10 μm, and dried at room temperature in the ultra-clean bench for 24 h, then wrapped the membrane with non-woven fabric, and continued to dry at 60 °C for 12 hours, and finally obtained the PAN-PVA / g-C3N4 pervaporation water-permeable hybrid membrane.

[0023] With 90wt.% ethanol-water as the me...

Embodiment 2

[0025] Embodiment 2: Different from Example 1, configuration 50 g mass fraction is 5wt.% g-C3N4 casting solution, and then it is coated on different supports (bottom film), when there is no bottom film, The film thickness is 50 μm, and other preparation and analysis methods are the same as in Example 1. The performance of the composite membrane prepared in embodiment 2 is as follows:

[0026] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com