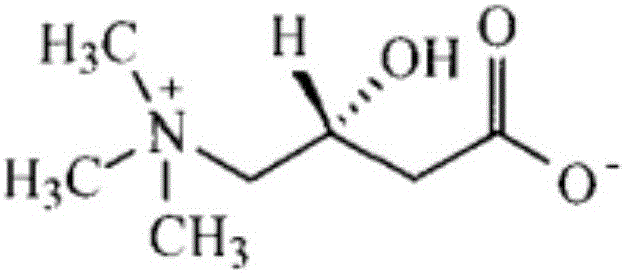

Levocarnitine composition for injection and preparation method thereof

A composition and injection technology, applied in the field of medicine, can solve the problems of long freeze-drying cycle, collapse of skeleton freeze-drying microstructure, influence, etc., and achieve the effects of ensuring reconstituted performance, improving freeze-drying efficiency, and excellent freeze-drying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

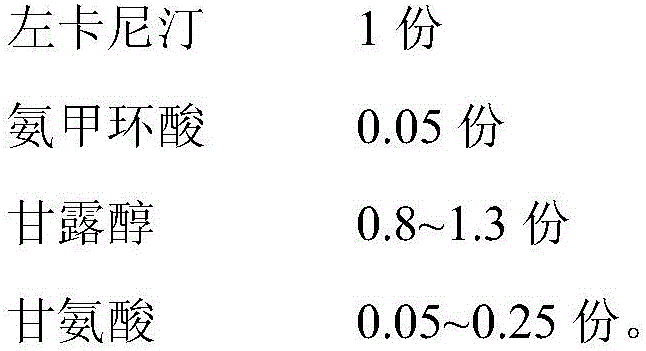

[0037] prescription:

[0038]

[0039] Preparation: Weigh levocarnitine, tranexamic acid, mannitol and glycine, put them in a preparation tank, add water for injection, stir to dissolve completely and mix evenly, and adjust the pH to 5.7 with a pH regulator to obtain a medicinal solution;

[0040] Decarbonization and sterile filtration: add 0.01% activated carbon for needles by weight of the liquid medicine, continue to stir, heat the liquid medicine to 45°C and keep it warm for 30 minutes, perform coarse filtration with a titanium rod, and fine filtration with a 0.22 μm microporous membrane;

[0041] Aseptic subpackaging: subpackage the filtered medicinal solution in 8ml / bottle into vials, and half-stopper;

[0042] Vacuum freeze-drying: pre-freeze at -45°C to -40°C for 3 to 5 hours, keep at -10°C for 7 to 8 hours, keep at 10°C for 6 to 7 hours, and then dry at 50°C for 5 hours;

[0043] Plugging, capping, packaging, full inspection, storage.

Embodiment 2

[0045] prescription:

[0046]

[0047]

[0048] Preparation: Weigh levocarnitine, tranexamic acid, mannitol and glycine, put them in a preparation tank, add water for injection, stir to dissolve completely and mix evenly, and adjust the pH to 6.3 with a pH regulator to obtain a medicinal solution;

[0049] Decarbonization and sterile filtration: add 0.3% activated carbon for needles by weight of the liquid medicine, continue to stir, heat the liquid medicine to 45°C and keep it warm for 30 minutes, perform coarse filtration with a titanium rod, and fine filtration with a 0.22 μm microporous membrane;

[0050] Aseptic subpackaging: subpackage the filtered medicinal solution in 8ml / bottle into vials, and half-stopper;

[0051] Vacuum freeze-drying: pre-freeze at -45°C to -40°C for 3 to 5 hours, keep at -10°C for 7 to 8 hours, keep at 10°C for 6 to 7 hours, and then dry at 50°C for 5 hours;

[0052] Plugging, capping, packaging, full inspection, storage.

Embodiment 3

[0054] prescription:

[0055]

[0056] Preparation: Weigh levocarnitine, tranexamic acid, mannitol and glycine, put them in a preparation tank, add water for injection, stir to dissolve completely and mix evenly, and adjust the pH to 6.1 with a pH regulator to obtain a medicinal solution;

[0057] Decarbonization and sterile filtration: add 0.1% active carbon for needles by weight of the liquid medicine, continue to stir, heat the liquid medicine to 45°C and keep it warm for 30 minutes, perform coarse filtration with a titanium rod, and fine filtration with a 0.22 μm microporous membrane;

[0058] Aseptic subpackaging: subpackage the filtered medicinal solution in 8ml / bottle into vials, and half-stopper;

[0059] Vacuum freeze-drying: pre-freeze at -45°C to -40°C for 3 to 5 hours, keep at -10°C for 7 to 8 hours, keep at 10°C for 6 to 7 hours, and then dry at 50°C for 5 hours;

[0060] Plugging, capping, packaging, full inspection, storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com