Heat preservation container capable of quickly transferring heat and preparing method of heat preservation container

A heat preservation container and heat container technology, applied in the field of household appliances, can solve the problems of lack of rapid and effective cooling, cannot be directly used, and carry heavy weight, etc., and achieve the effect of low processing cost, simple preparation method, and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

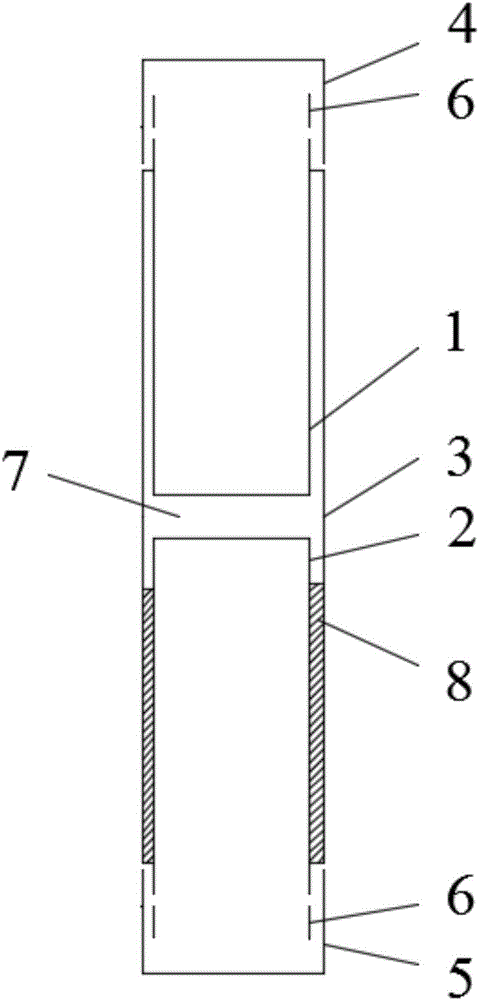

[0019] Such as figure 1 As shown, a thermal insulation container capable of rapid heat transfer includes a hot container 1, a cold container 2 and a shell 3 covering the outer surfaces of the two containers; the hot container 1 is an upper opening, and the cold container 2 is a lower opening The bottom of the hot container 1 corresponds to and does not touch the top of the cold container 2; the outer side of the hot container 1, the outer side of the cold container 2 and the outer shell 3 jointly form a closed vacuum cavity 7; The upper opening of the heat container 1 is provided with an upper end cover 4 and a gasket 6 is provided between the two; the lower opening of the cold container 2 is provided with a lower end cover 5 and a gasket 6 is provided between the two; The lower half of the vacuum cavity 7 is filled with a heat transfer medium 8 ; the height of the heat transfer medium 8 in the vacuum cavity 7 is lower than the bottom of the heat container 1 .

[0020] The up...

Embodiment 2

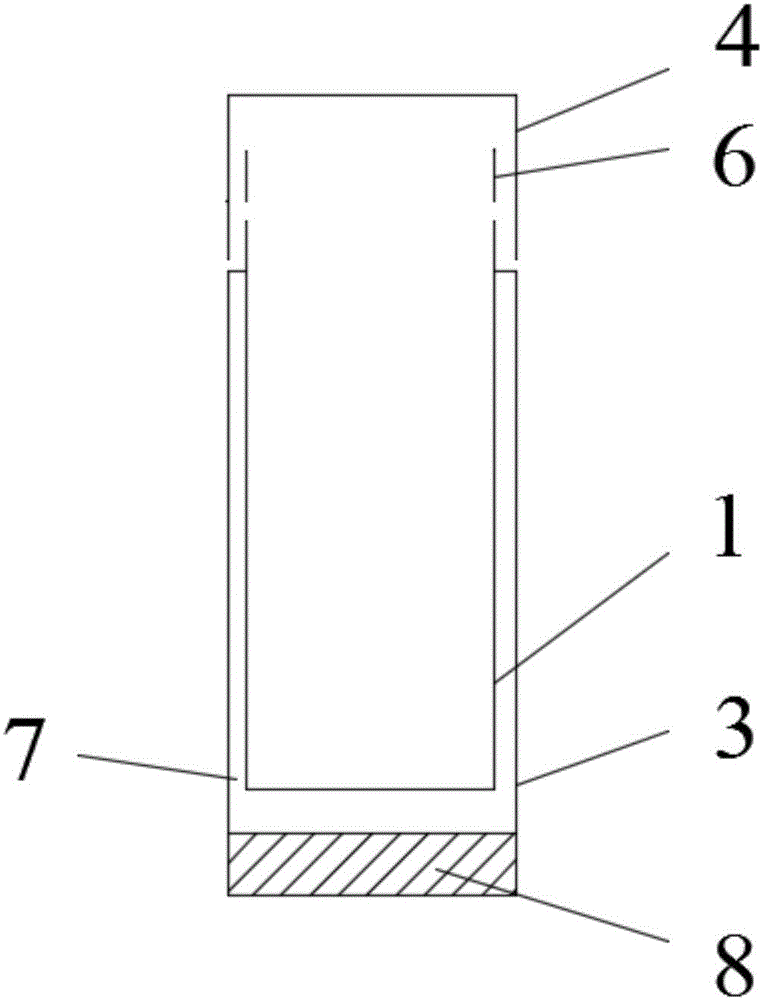

[0028] Such as figure 2 As shown, the present embodiment provides a thermal insulation container capable of rapid heat transfer, which includes a thermal container 1 and a shell 3 coated on the outer surface of the container; the thermal container 1 is an upper opening; the outer surface of the thermal container 1 and An airtight vacuum cavity 7 is formed between the shells 3; an upper end cover 4 is arranged at the upper opening of the heat container 1 and a sealing gasket 6 is arranged between the two; the bottom of the vacuum cavity 7 is filled with Heat medium 8; the height of the heat transfer medium 8 in the vacuum cavity 7 is lower than the bottom of the heat container 1 .

[0029] In the process of using the heat preservation container capable of rapid heat transfer in this embodiment, the heat container is filled with hot liquid, which can keep heat for a long time in a normal storage state, that is, the outside of the heat container is a vacuum, which is conducive t...

Embodiment 3

[0031] A method for preparing a heat-insulating container capable of rapid heat transfer, specifically carried out according to the following steps: firstly, the container is welded on the shell 3, and a process opening is left, so that the shell 3 and the outer surface of the container form a closed cavity Then, vacuumize the airtight cavity through the process port, after the vacuuming is completed, inject the heat transfer medium into the cavity through the process port, the height of the heat transfer medium 8 in the vacuum cavity 7 is lower than the bottom of the heat container 1; Finally, the process port is sealed; the method of sealing the process port is welding seal, colloid seal or elastic material seal.

[0032] The thermal insulation container capable of rapid heat transfer in the above embodiments can keep heat for a long time under the normal placement state, and can transfer the heat quickly through the phase change of the heat transfer medium under the upside d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com