Interline stubble breaking machine for interplanted corns

A stubble crusher and frame technology, which is applied in the fields of soil preparation machinery, agricultural machinery and implements, and applications, to achieve the effects of reducing labor intensity, high operating efficiency, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

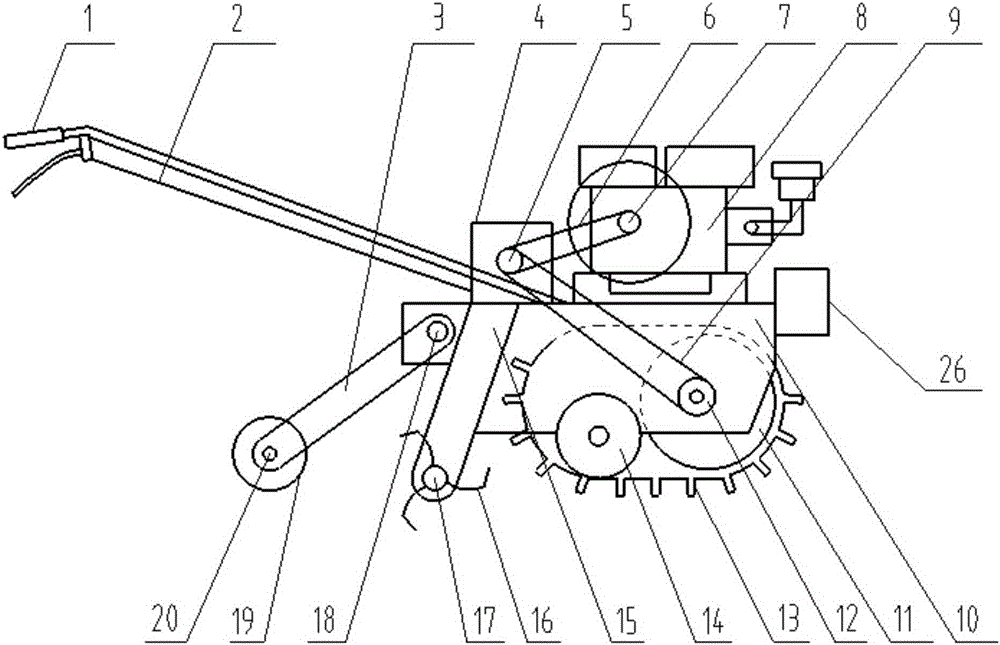

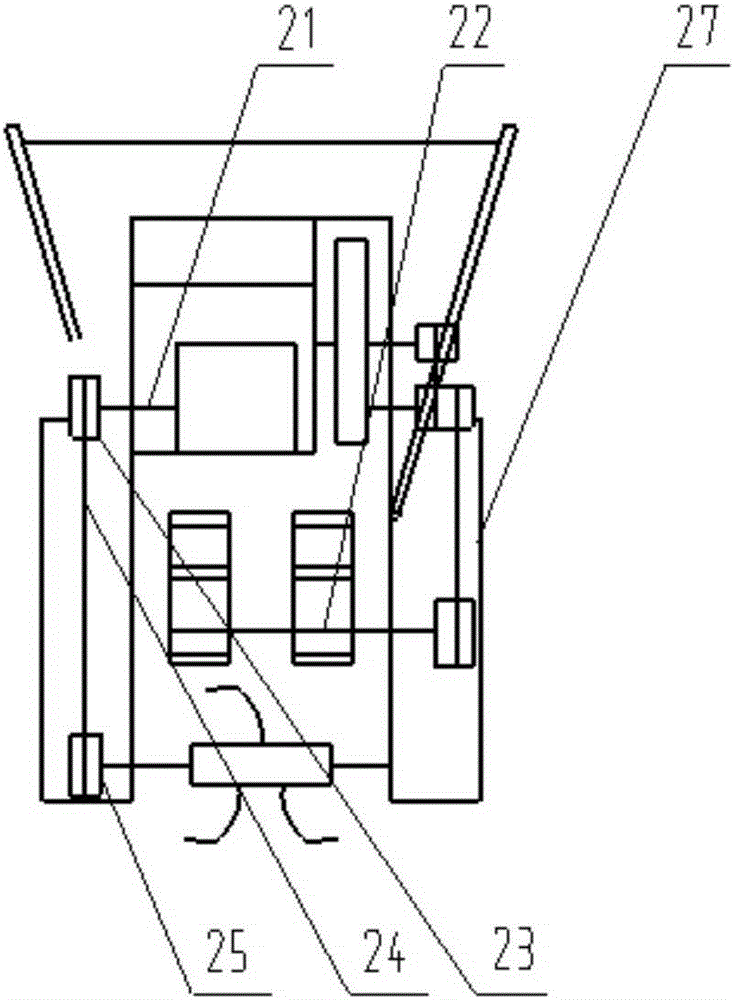

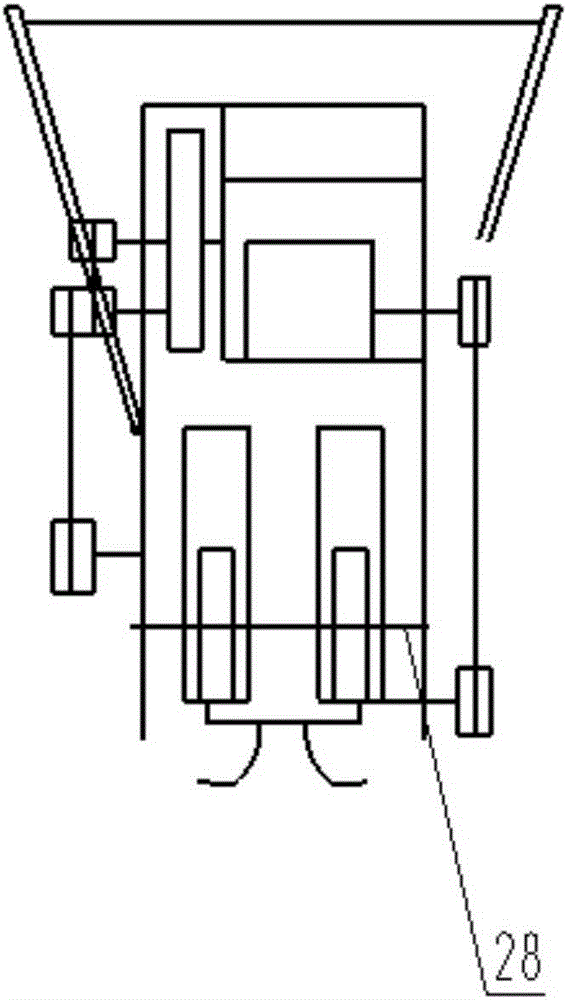

[0014] A kind of interplanting corn interrow stubble breaker of the present invention, as shown in the accompanying drawing, it is made up of handle 1, shift lever 2, traveling wheel frame 3, gearbox 4, gearbox pulley 5, gearbox drive belt 6 , Diesel engine pulley 7, diesel engine 8, crawler drive belt 9, frame 10, crawler drive wheel 11, crawler pulley 12, crawler belt 13, guide wheel 14, rotary tillage frame 15, rotary tillage harrow teeth 16, rotary tillage harrow shaft 17 , travel wheel frame shaft 18, travel wheel 19, travel wheel shaft 20, gearbox shaft 21, track shaft 22, rotary tillage main pulley 23, rotary tillage drive belt 24, rotary tillage slave pulley 25, counterweight 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com