High-strength rare earth ytterbium heat-resistant steel and manufacture method thereof

A manufacturing method and high-strength technology, applied in the field of high-temperature heat-resistant steel, can solve problems such as reducing the high-temperature strength of heat-resistant steel, and achieve the effects of improving high-temperature strength, preventing diffusion and aggregation, and maintaining high-temperature strength

Active Publication Date: 2016-12-28

BAOSTEEL DESHENG STAINLESS STEEL

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the high-temperature strength of 310S heat-resistant steel is mainly guaranteed by the carbon content, and reducing the carbon content will inevitably reduce the high-temperature strength of the heat-resistant steel

Therefore, at present, we have to comprehensively consider the high temperature strength and service life, and control the carbon content of 310S heat-resistant steel according to the middle and lower limits

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0064] The present invention will be further described below in conjunction with embodiment.

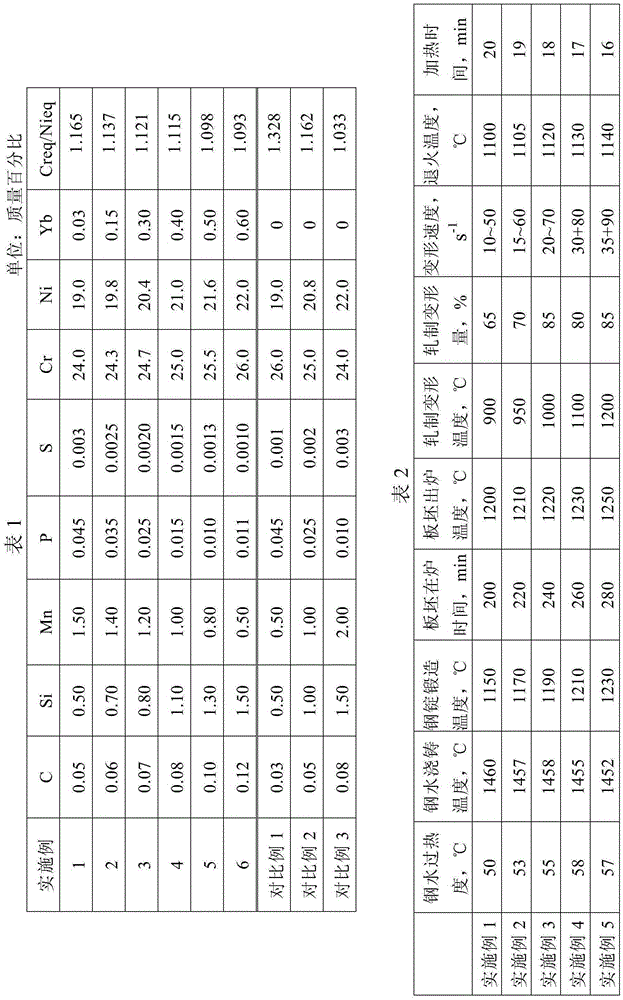

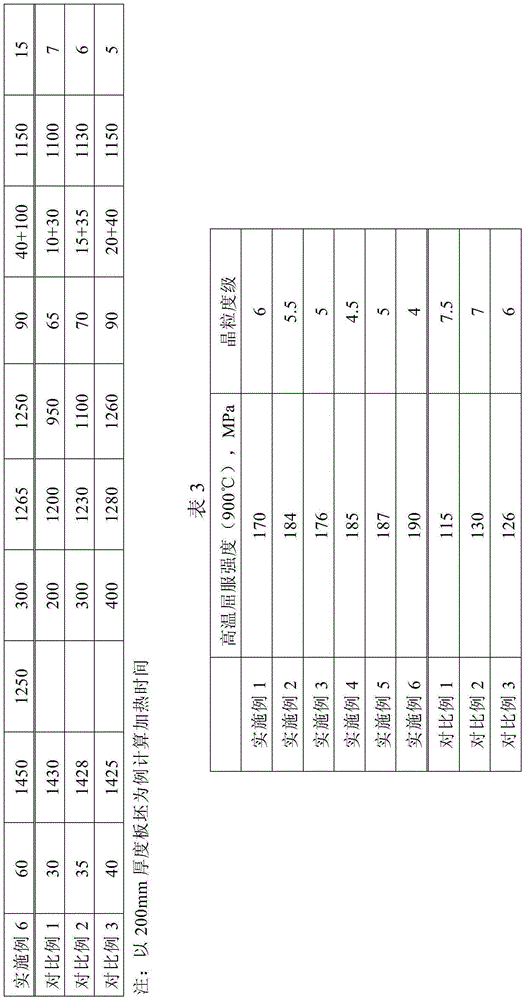

[0065] Examples of steel components of the present invention are shown in Table 1, Table 2 is the manufacturing process of the steel examples of the present invention, and Table 3 is the mechanical properties of the steel examples of the present invention.

[0066]

[0067]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to high-strength rare earth ytterbium heat-resistant steel and a manufacture method thereof. The heat-resistant steel comprises the following chemical components by mass percentage: 0.05-0.12% of C, 0.2-1.5% of Si, 0.5-1.7% of Mn, less than or equal to 0.045% of P, less than or equal to 0.030% of S, 24.0-26.0% of Cr, 19.0-22.0% of Ni, 0.03-0.6% of Yb, and the balance of Fe and the unavoidable impurity element; and the following condition should be simultaneously satisfied: Creq / Nieq is less than or equal to 1.165, Creq is Cr+1.5Si, and Nieq is Ni+30C+0.5Mn. By adding rare earth ytterbium, crystal boundary intensity is increased, the method provides favorable condition for increasing carbon content in the heat resistant steel, so that the high temperature intensity and service life of the steel are increased, the reasonable manufacturing process condition is cooperated, under guarantee of mechanical properties, the grain size of the heat-resistant steel can reach 4-6 grade, and the steel antioxidation performance is increased.

Description

technical field [0001] The invention relates to the field of heat-resistant steel for high temperature, in particular to a high-strength rare earth ytterbium heat-resistant steel and a manufacturing method thereof. Background technique [0002] 310S heat-resistant steel is a heat-resistant steel that has been used in high-temperature fields for a long time. Its high-chromium and high-nickel alloy composition makes it have better high-temperature heat resistance. However, due to long-term use under high temperature conditions, the carbon content in the steel aggregates at high temperatures, causing microscopic holes in the steel material, causing internal defects in the material structure, resulting in a decrease in material strength and failure. Reducing the carbon content in steel plays a certain role in the high-temperature accumulation of carbon, which can prolong the high-temperature service life of 310S heat-resistant steel. However, the high-temperature strength of 31...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58C22C38/40C21D8/02

Inventor 叶晓宁黄俊霞

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com