Induction heating coil and heating method thereof

A technology of induction heating coils and heating methods, which is applied in the direction of induction heating, coil devices, electric heating devices, etc., can solve problems such as difficulty in ensuring brazing quality and uneven distribution of magnetic beams, and achieve brazing quality and short production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

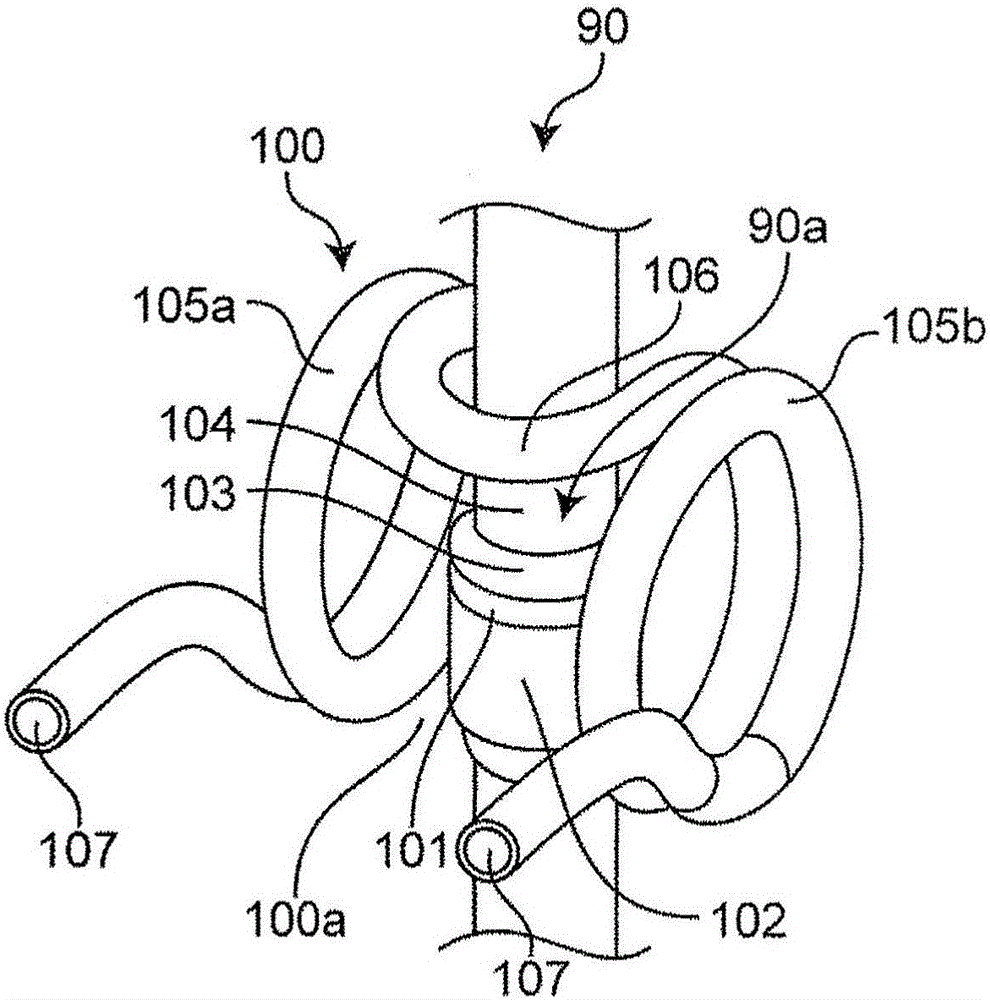

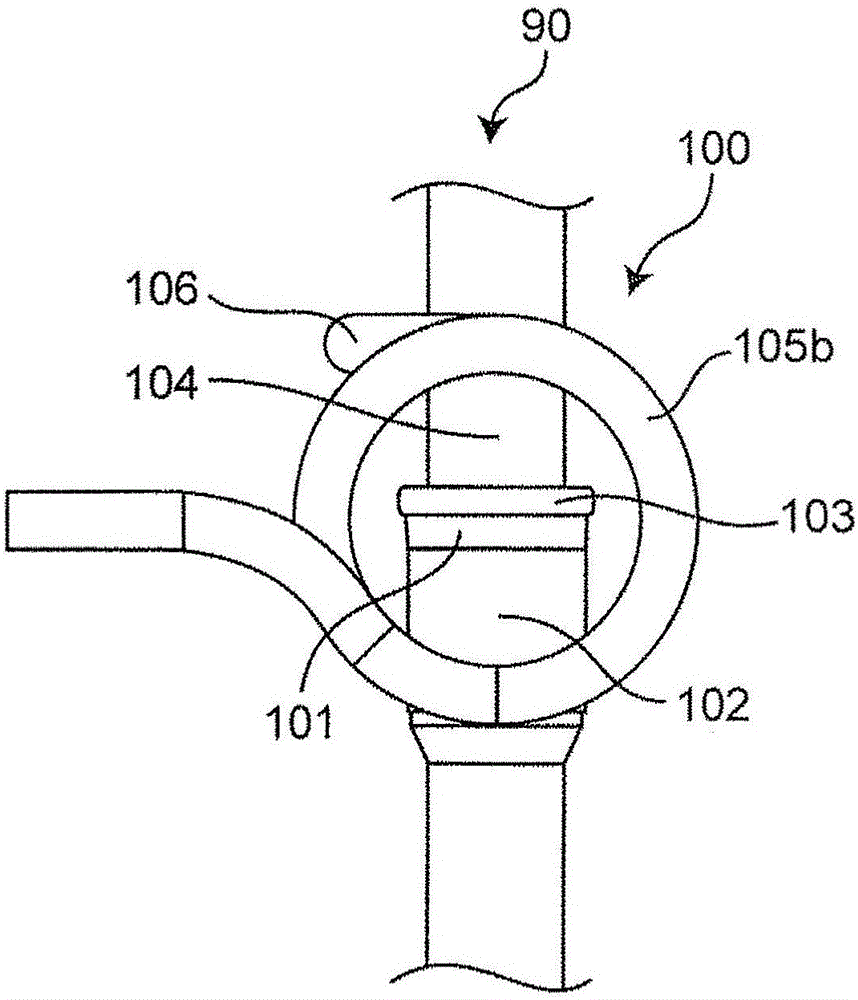

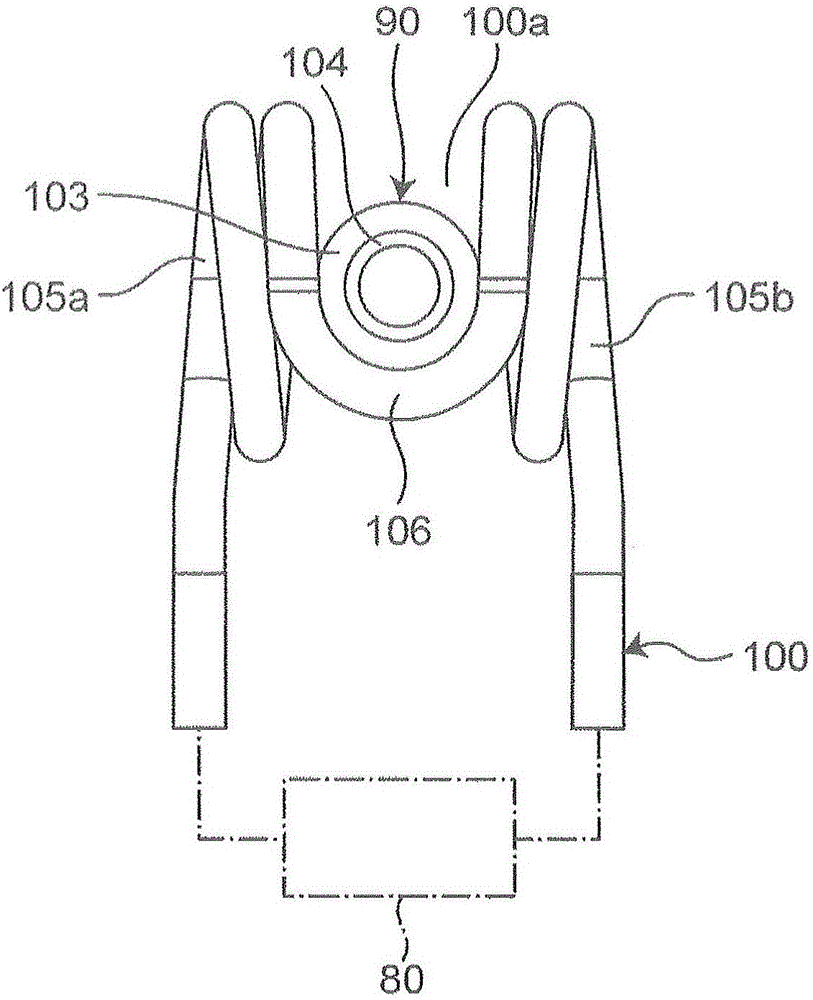

[0079] Figure 1A It is a diagram showing the structure of the induction heating device used in the heating method according to the first embodiment of the present invention, that is, the induction heating coil 100 for brazing the heat transfer pipe 102 and the joint pipe 104 which are two metal pipes . also, Figure 1B It is a configuration diagram of the induction heating coil 100 viewed from the side. Figure 1C It is a configuration diagram of the induction heating coil 100 viewed from above. Figure 1D It is a configuration diagram of the induction heating coil 100 viewed from the front. Figure 2A ~ Figure 2E It is an explanatory drawing showing each process of the joining method of the heat transfer pipe 102 which is two metal pipes, and the joint pipe 104 concerning 1st Embodiment of this invention.

[0080] The induction heating coil 100 arranges the brazing part 90a of the object to be heated 90 in the part to be heated (the space to be heated or the region to be...

no. 2 Embodiment approach

[0112] Figure 6A It is a configuration diagram of an induction heating coil 100B for brazing a heat transfer pipe 202 , which is a metal pipe, and a joint pipe 204 according to the second embodiment of the present invention. Figure 6B It is a configuration diagram viewed from the side of the induction heating coil 100B. Figure 6C It is a structural diagram seen from the back surface of the induction heating coil 100B. Figure 6D It is a configuration diagram viewed from above the induction heating coil 100B. As an example, the induction heating coil 100B is formed of a copper tube, and the cooling water 207 flows through the copper tube.

[0113] The induction heating coil 100B is largely different from the first embodiment in that the connecting portion 206 is arranged on the heating target portion 100Ba with respect to the end of the heat transfer pipe 202 as the first metal pipe and the joint pipe 204 as the second metal pipe. The ends and the brazing filler metal 203...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com