A Grading Design Method of Mineral Aggregate to Improve the Mechanical Properties of Asphalt Mixture

A technology of asphalt mixture and design method, applied in the direction of design optimization/simulation, calculation, instrument, etc., can solve problems such as inability to determine the optimal grading composition of aggregates, lack of scientific support, etc., to improve road performance and mechanical properties , the design process is intuitive, and the effect of fatigue life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

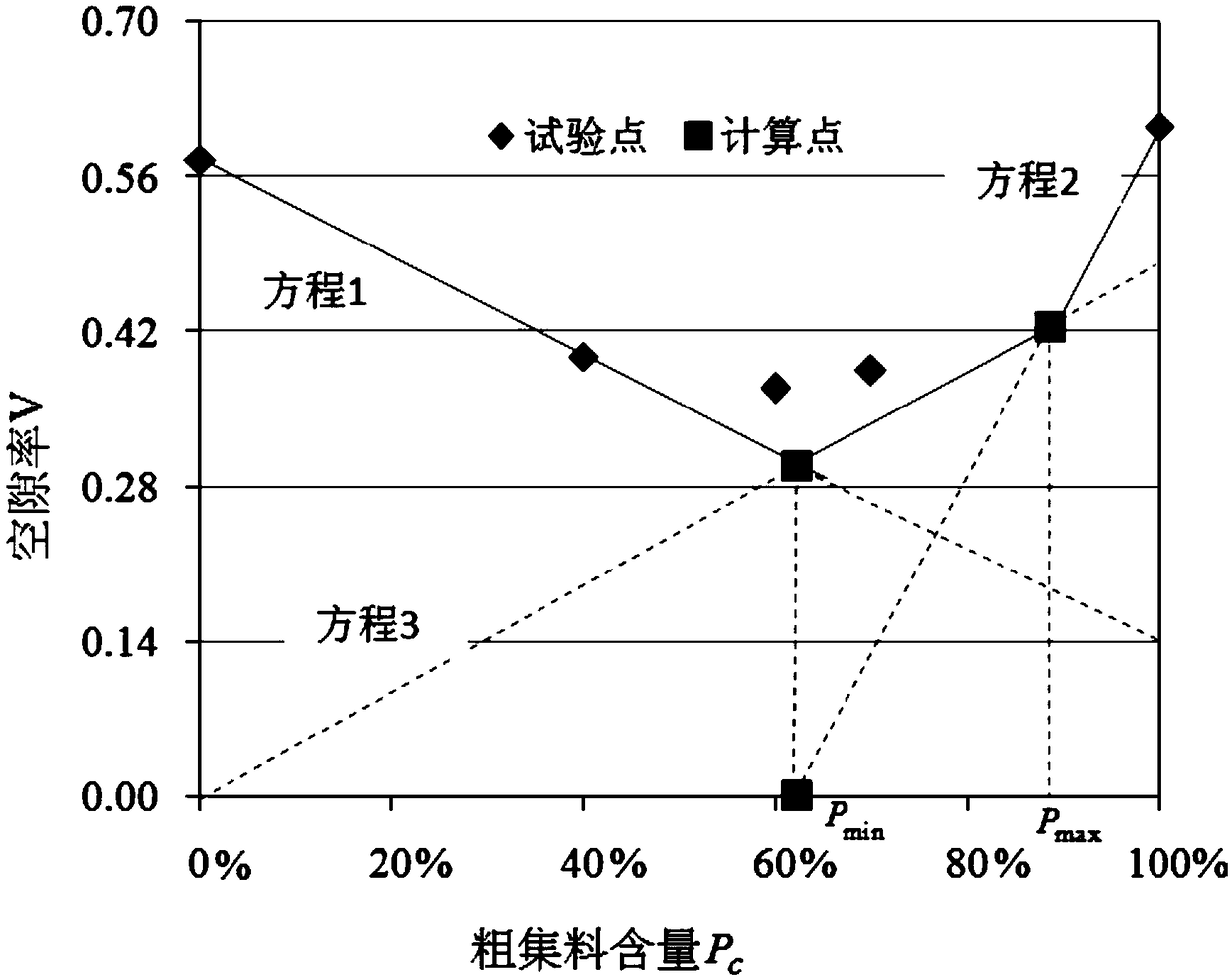

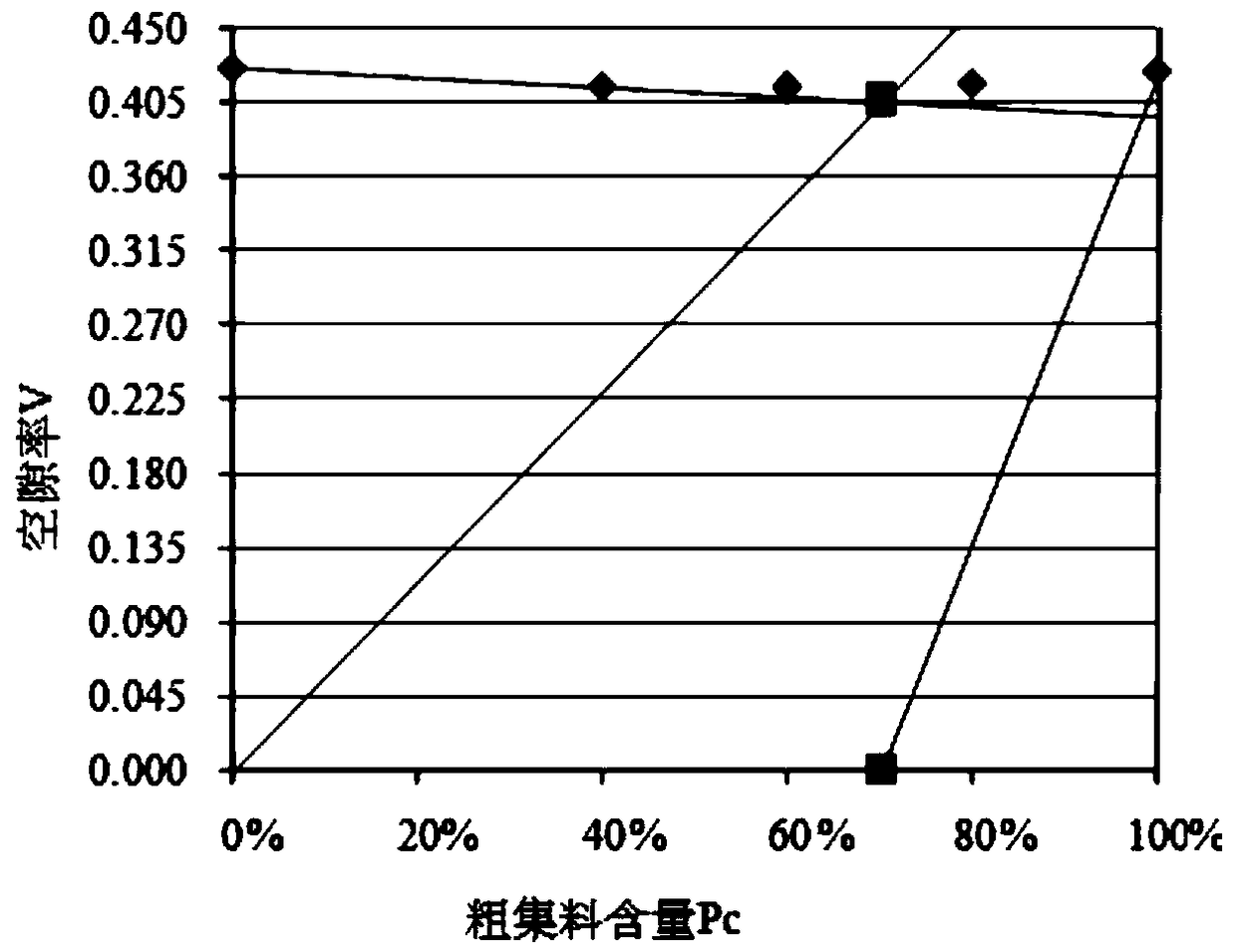

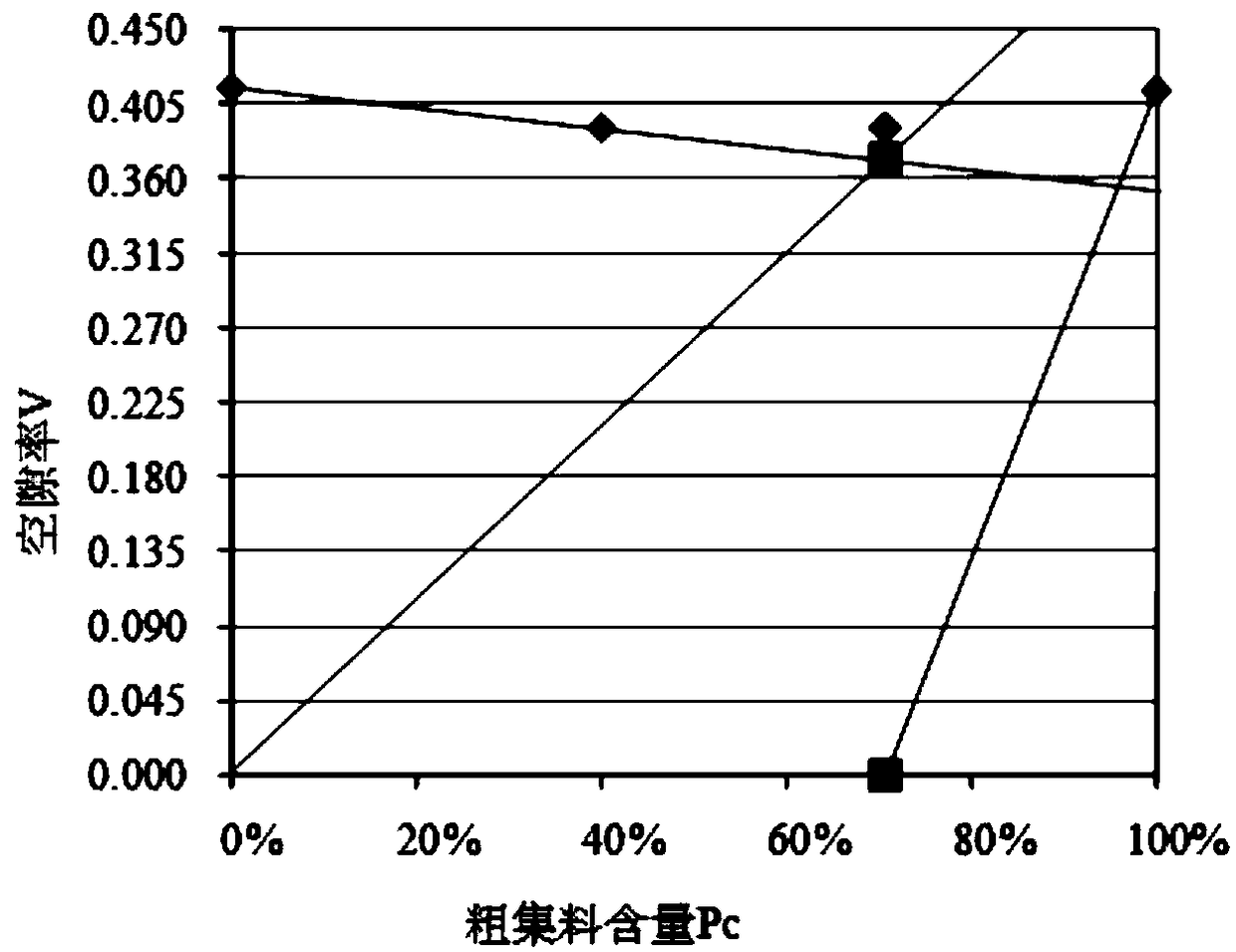

[0048] A mineral aggregate gradation design method to improve the mechanical properties of asphalt mixture, using this method to design aggregate mineral aggregate gradation with a maximum nominal particle size of 20mm, and comparing the performance of the aggregate before and after gradation optimization.

[0049] S1. According to the maximum nominal particle size of the aggregate of the mixture is 20mm, the aperture of the selected sieve is: 19.0mm, 16.0mm, 13.2mm, 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm, 0.075mm; 19.0mm, 13.2mm, 9.5mm, 4.75mm and 2.36mm sieve holes are regarded as key sieve holes, and aggregates are divided into 13.2mm-19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com