Non-destructive metal surface defect microscopic detection method

A technology for metal surface and microscopic inspection, which is applied in the direction of optical testing for flaws/defects, measuring devices, and material analysis through optical means. Higher requirements and other issues, to achieve the effect of wide application range, high promotion value, and increase product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

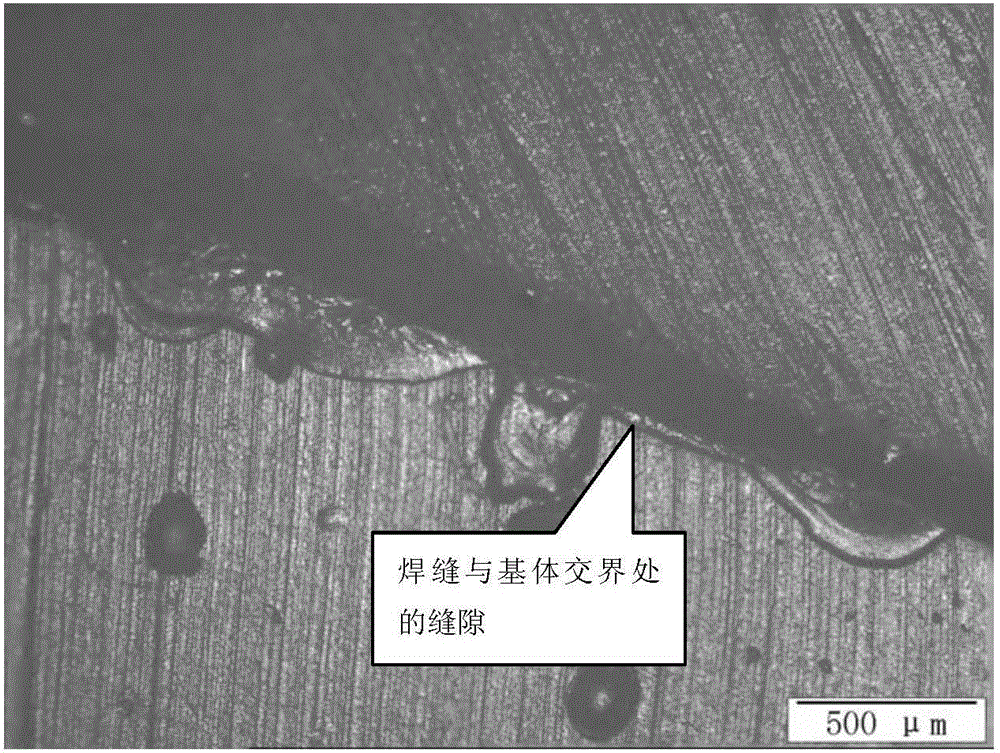

[0031] see figure 1 , taking the electron beam welding between GH188 thin-wall and GH536 thin-wall, as an example, it is found that there are suspected cracks displayed linearly near the weld by fluorescence, and the specific implementation steps are described as follows:

[0032] Since the fluorescent display part is located in the weld seam, it is not easy to judge whether the linear display is a crack, so the surface treatment is not performed on this part, and it is directly detected.

[0033] 1. Clean the fluorescent display position of the welding seam with a cotton ball soaked in acetone.

[0034] 2. Dry the weld surface with a hair dryer.

[0035] 3. Cut the AC paper into strips with a width of 15mm and a length of 40mm.

[0036] 4. Clamp the pre-cut AC paper with tweezers, suck an appropriate amount of acetone with a small dropper, first drop a few drops on the surface of the weld to be tested, so that it soaks the entire surface to be tested, and then drop acetone ...

Embodiment 2

[0043] After a certain forging was processed, the corrosion process inspection was carried out, and it was found that there were abnormal displays in some areas, see Figure 4 , in order to observe the metal microstructure, surface treatment is carried out on the abnormal display area. Then, according to the method of Example 1, the AC paper was covered on the abnormal display position and rubbed, and then the AC paper was observed microscopically. see Figure 5 , Image 6 , there is a significant difference in the grain size level between the abnormal display area and the normal area, the grain size of the normal area is 10, and the grain size of the abnormal display area is 5. According to the results of microscopic observation, the relevant standards are used to determine whether the part can be used in this situation.

[0044] The method of the present invention has the advantages of simple operation and wide application range, and the type of defects can be judged by o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com