Natural latex preserving method and prepared latex product

A natural latex and preservation method technology, applied in the field of natural latex, can solve problems such as difficulty in vulcanization, stimulation of human health, and impact on product exports, etc., to achieve the effects of benefiting human health, less stimulating odor, and promoting microcirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

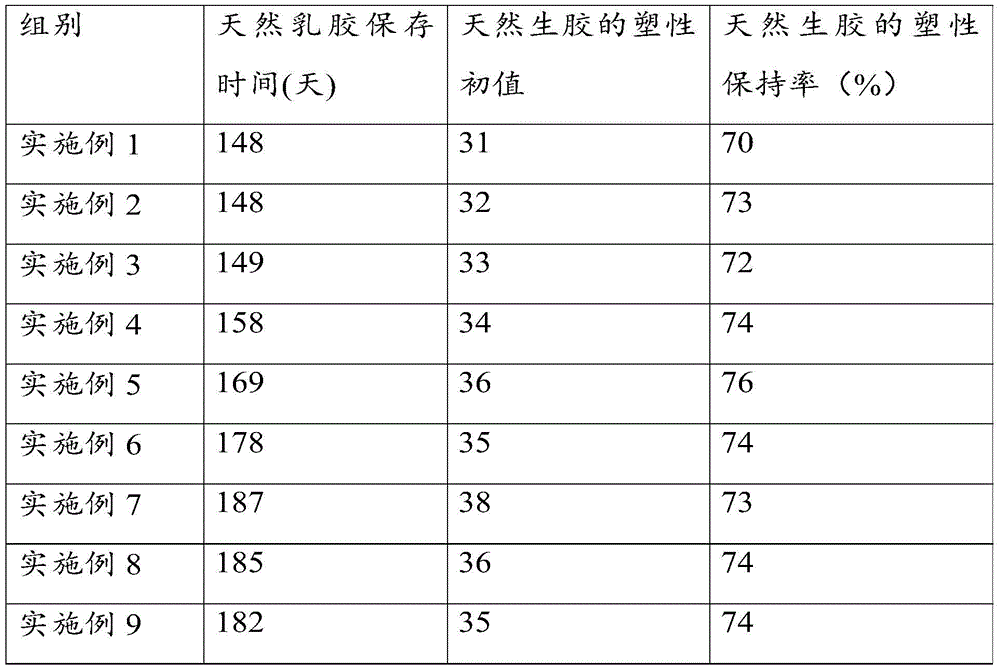

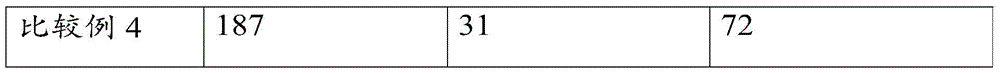

[0081] In fresh latex, add the bamboo charcoal of different quality respectively and preserve, be respectively embodiment 1-10. In embodiment 1, the percentage that the addition of bamboo charcoal accounts for fresh latex quality is 0.1%; Among embodiment 2, the percentage that the addition of bamboo charcoal accounts for fresh latex quality is 0.3%; In embodiment 3, the addition of bamboo charcoal accounts for the percentage of fresh latex quality The percentage of quality is 0.5%; In embodiment 4, the percentage that the addition of bamboo charcoal accounts for fresh latex quality is 0.7%; In embodiment 5, the percentage that the addition of bamboo charcoal accounts for fresh latex quality is 1%; In embodiment 6, The percentage that the addition of bamboo charcoal accounts for fresh latex quality is 3%; In embodiment 7, the percentage that the addition of bamboo charcoal accounts for fresh latex quality is 5%; Among the embodiment 8, the percentage that the addition of bamboo...

Embodiment 11~16

[0083] In the fresh latex, add its mass percent to be 0.5% bamboo charcoal, add dispersing agent simultaneously, make bamboo charcoal reach better dispersion effect, be beneficial to natural latex preservation. In embodiment 11, the dispersant that adds is carboxymethyl cellulose sodium, and addition is 0.02% of fresh latex weight; Among embodiment 12, the dispersant that adds is polyvinyl alcohol, and addition is 0.02% of fresh latex weight In embodiment 13, the dispersant that adds is sodium dodecylbenzene sulfonate, and addition is 0.04% of fresh latex weight; In embodiment 14, the dispersant that adds is sodium dodecylbenzene sulfonate and spit The mixture of temperature 80, the addition is 0.05% of fresh latex weight; Among the embodiment 15, the dispersant that adds is the mixture of sodium carboxymethyl cellulose, polyvinyl alcohol, Tween 80 and sodium lauryl sulfate, adds Amount is 0.25% of fresh latex weight; In embodiment 16, the dispersing agent that adds is sodium ...

Embodiment 17~22

[0085]In the fresh latex, add its mass percentage to be 0.5% bamboo charcoal, add other natural latex preservative simultaneously, to reach better preservation effect. Embodiment 17 adds chitosan, and addition is 0.1% of fresh latex weight; Embodiment 18 adds liquid ammonia, and addition is 0.1% of fresh latex weight; Embodiment 19 adds liquid ammonia, and addition is 0.05% of fresh latex weight. %; Embodiment 20 adds liquid ammonia, and addition is 0.3% of fresh latex weight; Embodiment 21 adds the mixture of sodium pentachlorophenate and mercaptan benzothiazole, and addition is 0.1% of fresh latex weight; Embodiment 22 Add the mixture of liquid ammonia, chitosan, sodium pentachlorophenate, mercaptobenzothiazole and dihydroxypropyl dodecanoic acid in an amount of 0.1% of the fresh latex weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com