Concrete early strength agent and preparation method thereof

An early-strength agent and concrete technology, which is applied in the field of additives for concrete construction and its preparation, can solve the problems of increasing equipment investment and operating costs, increasing energy consumption, etc., to avoid steam curing procedures, reduce energy consumption, shorten The effect of steaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

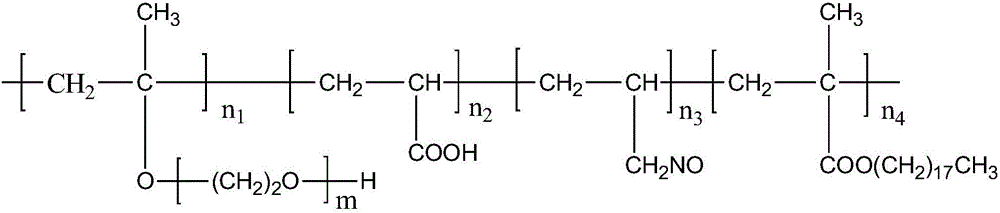

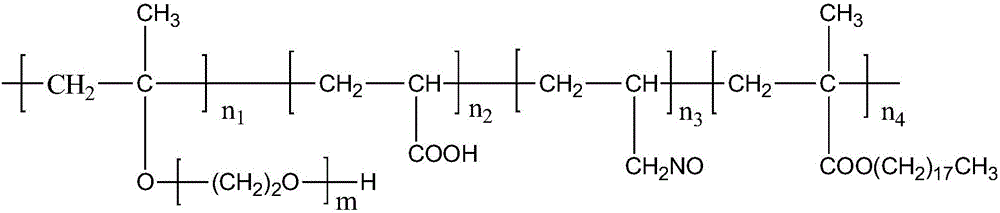

[0030] 10g of methacrylic acid, 1.94g of maleimide, 20.34g of 2-methyl-2-octadecyl acrylate and 51.7g of deionized water were stirred evenly to obtain a monomer solution; 3.448g of ferrous ammonium sulfate dissolved in 38.8 g of deionized water and stirred uniformly to obtain an initiator solution; 0.862 g of n-dodecyl mercaptan and 12.9 g of deionized water were uniformly stirred to obtain a chain transfer agent solution.

[0031] 120g of methyl alkenyl polyoxyethylene ether with a relative molecular weight of 1200, 20.1g of methacrylic acid and 155.1g of deionized water were mixed and stirred and heated to 40°C, and the prepared initiator solution was added to the reaction system within 3 hours , after stirring for 5 minutes, add the prepared monomer solution and chain transfer agent solution to the reaction system dropwise at a constant speed, and continue to keep warm for 1 hour after dropping, and the temperature of the reaction system is controlled at 40°C during the drop...

Embodiment 2

[0033] Stir 7.2g of acrylic acid, 1.42g of acrylamide, 16.95g of 2-methyl-2-octadecyl acrylate and 84g of deionized water to obtain a monomer solution; dissolve 1.4g of sodium bisulfite in 58.8g of deionized Stir uniformly in water to obtain an initiator solution; stir 0.84 g of mercaptopropionic acid and 25.2 g of deionized water uniformly to obtain a chain transfer agent solution.

[0034] Mix and stir 240g of methyl alkenyl polyoxyethylene ether with a relative molecular weight of 2400, 14.4g of acrylic acid and 252g of deionized water and heat up to 38°C, add the prepared initiator solution into the reaction system within 2.5h, stir After 5 minutes, add the prepared monomer solution and chain transfer agent solution to the reaction system dropwise at a constant speed, and continue to keep warm for 0.5h after dropping, and the temperature of the reaction system is controlled at 38°C during the dropping and keeping; add potassium hydroxide aqueous solution Adjust the pH valu...

Embodiment 3

[0036] Stir 8.2g of maleic anhydride, 3.55g of acrylamide, 10.17g of 2-methyl-2-octadecyl acrylate and 65.5g of deionized water to obtain a monomer solution; dissolve 5.24g of concentrated sulfuric acid in 52.4g of Stir uniformly in deionized water to obtain an initiator solution; stir 0.218 g of mercaptoacetic acid and 13.1 g of deionized water uniformly to obtain a chain transfer agent solution.

[0037] 180g of methyl alkenyl polyoxyethylene ether with a relative molecular weight of 1800, 16.3g of maleic anhydride and 196.4g of deionized water were mixed and stirred and heated to 42°C, and the prepared initiator solution was added to the reaction within 2.5h system, after stirring for 5 minutes, add the prepared monomer solution and chain transfer agent solution to the reaction system dropwise at a uniform speed, and continue to keep warm for 1.5 hours after dropping, and the temperature of the reaction system is controlled at 42°C during the dropping and keeping; Sodium ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com