Preparation method for modified barium titanate ceramics

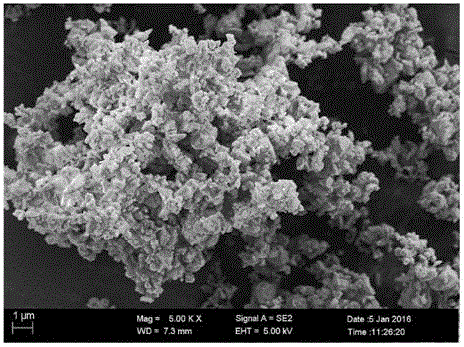

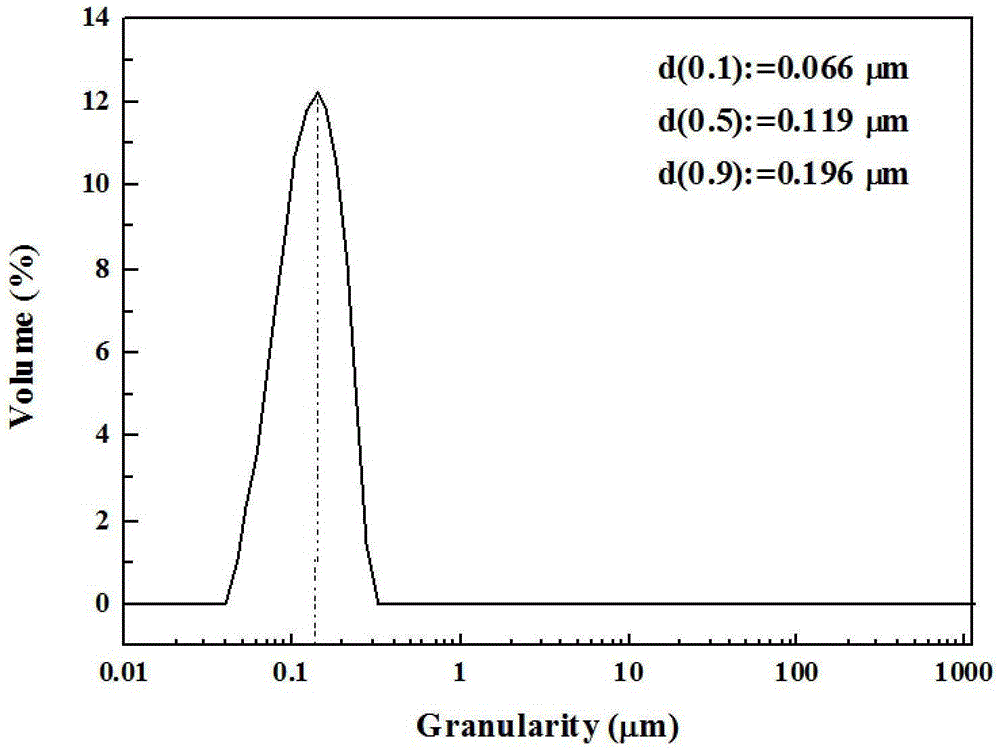

A barium titanate and modification technology is applied in the field of preparation of modified barium titanate ceramics, which can solve the problems of large fluctuation of dielectric coefficient, low qualified rate of finished products, uneven sintering, etc., and achieves low labor intensity and fine particle size. , saving time and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for modifying barium titanate ceramics suitable for supercapacitors, the specific preparation method is as follows:

[0042] 1. Select 8.13kg of tin dioxide, 5.955kg of calcium carbonate, 5.955kg of barium carbonate, 0.615kg of titanium dioxide, and 0.3kg of titanium dioxide and put them into the mixer for uniform mixing for 2 hours to obtain the auxiliary material mixture;

[0043]2. Take out the auxiliary material mixture and put it into the sagger for vibration and vibration, so that the material is fully dense. Poke out evenly honeycomb-shaped exhaust ports on the auxiliary material mixture, and then put it into the muffle furnace for sintering. When sintering, the initial The temperature is normal temperature, and the highest temperature is 1400°C. When the normal temperature is -1100°C, the heating rate is controlled to be 400°C / h, and when the temperature is 1100°C-1400°C, the heating rate is controlled to be 300°C / h. And heat preservation at 1100°C for ...

Embodiment 2

[0053] A method for modifying barium titanate ceramics suitable for supercapacitors, the specific preparation method is as follows:

[0054] 1. Select 8.13kg of tin dioxide, 5.955kg of calcium carbonate, 5.955kg of barium carbonate, 0.615kg of titanium dioxide, and 0.3kg of titanium dioxide and put them into the mixer for uniform mixing for 2 hours to obtain the auxiliary material mixture;

[0055] 2. Take out the auxiliary material mixture and put it into the sagger for vibration and vibration, so that the material is fully dense. Poke out evenly honeycomb-shaped exhaust ports on the auxiliary material mixture, and then put it into the muffle furnace for sintering. When sintering, the initial The temperature is normal temperature, the highest temperature is 1400°C, the controlled heating rate is 400°C / h when the normal temperature is -1100°C, and the controlled heating rate is 300°C / h when the temperature is 1100°C-1400°C. And heat preservation at 1100°C for 90 minutes, and h...

Embodiment 3

[0065] A method for modifying barium titanate ceramics suitable for supercapacitors, the specific preparation method is as follows

[0066] 1. Select 8.13kg of tin dioxide, 5.955kg of calcium carbonate, 5.955kg of barium carbonate, 0.615kg of titanium dioxide, and 0.3kg of titanium dioxide and put them into the mixer for uniform mixing for 2 hours to obtain the auxiliary material mixture;

[0067] 2. Take out the auxiliary material mixture and put it into the sagger for vibration and vibration to make the material fully dense. Poke out evenly honeycomb-shaped exhaust ports on the auxiliary material mixture, and then put it into the muffle furnace for sintering. The initial temperature during sintering is Normal temperature, the maximum temperature is 1400°C, the control heating rate is 400°C / h when the normal temperature is -1100°C, and the control heating rate is 300°C / h when the temperature is 1100°C-1400°C. And heat preservation at 1100°C for 90 minutes, and heat preservat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com