Method for treating backflow fracturing fluid

A technology for fracturing flowback fluid and treatment methods, which is applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve problems such as complex control factors, complex components of fracturing flowback fluid, and secondary pollution. Achieve the effects of reducing costs, reducing the risk of secondary pollution, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

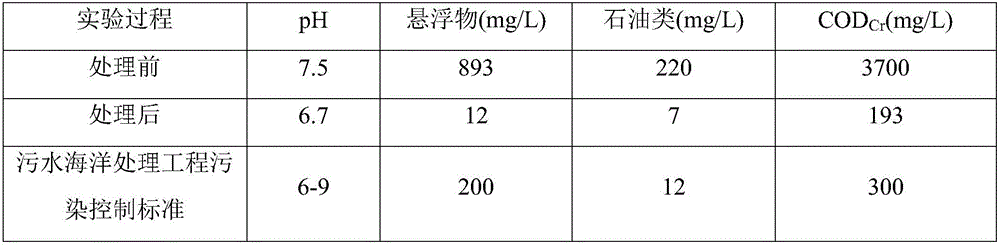

Embodiment 1

[0032] This embodiment is used to treat the fracturing flowback fluid of the hydroxypropyl guar gum system produced in the stimulation operation of offshore oil wells. Capacity: 20m 3 / h, influent water quality: PH=7.5, suspended matter in water is 893mg / L, COD is 3700mg / L, the treatment method is:

[0033] 1) The fracturing flowback fluid is subjected to ozone oxidation gel breaking treatment, which is used to reduce the viscosity of the fluid inlet port, alleviate the re-intervention of chemically soluble interference ions in the flowback fluid, and reduce the risk of secondary pollution. Among them, the ozone gas in the ozone oxidation gel breaking treatment is in the form of nano-sized microbubbles to improve the oxidation speed and oxidation efficiency. In the ozone gel breaking reaction, the ozone concentration is 50 mg / L, and the ozone gel breaking reaction time is 5 minutes.

[0034] The principle of ozone breaking reaction is:

[0035] o 3 +OH - →HO 2 ·+·O 2

...

Embodiment 2

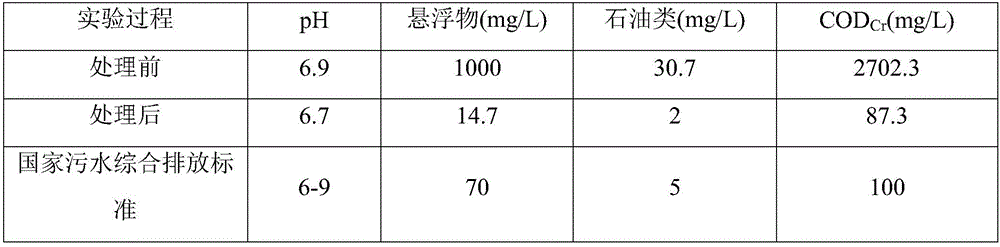

[0057] This embodiment is used to treat the fracturing flowback fluid of the slippery water system that does not require oxidation and gel breaking treatment. Capacity: 20m 3 / h, influent water quality: PH=6.9, suspended matter in water is 1000mg / L, COD is 2702.3mg / L, the operation steps are:

[0058] 1) Pump the slick water fracturing flowback fluid into the chemical flocculation unit, and the chemical flocculation uses flocculants and coagulants. The flocculant is selected from inorganic polymer flocculant solution, and the inorganic polymer flocculant solution is at least one of polyaluminum chloride, polyaluminum sulfate, polyferric sulfate, polyferric chloride and polyferric sulfate; coagulant polyacrylamide Solution; the dosage of flocculant is 1500mg / L, and the dosage of coagulant is 15mg / L; then it enters the electroflocculation reaction unit, and the suspended particles and colloidal pollutants in it lose stability under the action of electric field and combine with ...

Embodiment 3

[0065] This embodiment is used to treat the fracturing flowback fluid of the slippery water system that does not require oxidation and gel breaking treatment. Capacity: 20m 3 / h, influent water quality: PH=6.9, suspended matter in water is 1000mg / L, COD is 2702.3mg / L, the operation steps are:

[0066] 1) Pump the slick water fracturing flowback fluid into the electrocoagulation reaction unit, the suspended particles and colloidal pollutants in it lose stability under the action of the electric field and combine with the micro flocculant to form large flocs. The electrocoagulation reaction time is 4 minutes ;

[0067] 2) After the liquid treated in step 1 is mixed with dissolved air water, it enters the air flotation settling tank, the air-water mixing ratio is 5%, and the air flotation reaction time is 10 minutes; the settling tank is connected with the centrifugal desolidification device for flocculation After the sedimentation, the treatment liquid is discharged into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com