A kind of hollow graphene microspheres with high specific surface area and many folds and preparation method thereof

A technology with high specific surface area and graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of not fully showing the superior performance of graphene and small specific surface area, so as to reduce the chance of stacking and increase the ratio Surface area, the effect of reducing the number of stacked layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Graphene oxide microspheres were obtained by spraying and drying a graphene oxide aqueous solution with a concentration of 4 mg / mL. The atomization drying temperature is 120°C

[0017] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 800°C at 20°C / min and maintained for 10 minutes, and then heated to 3000°C at 5°C / min for graphitization.

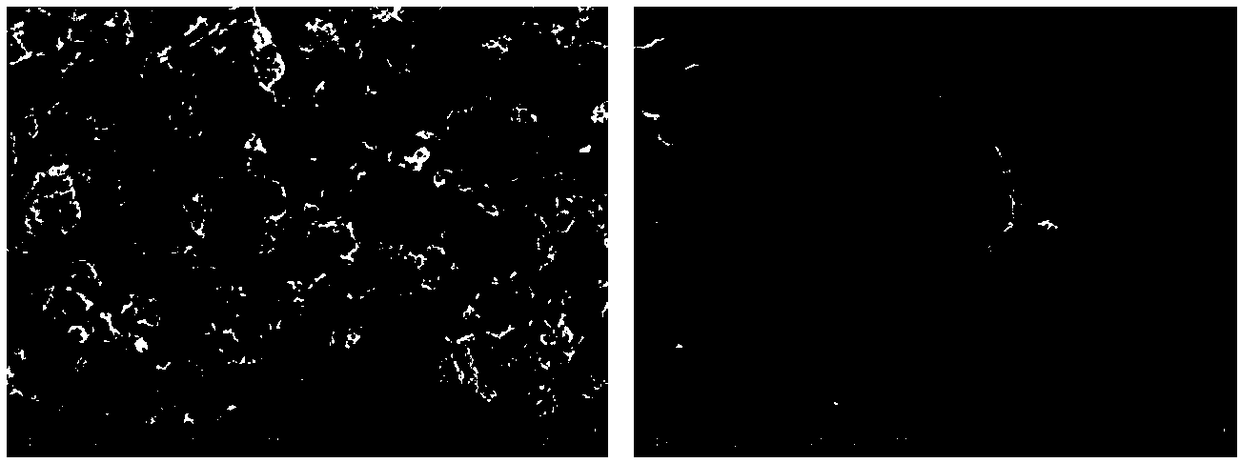

[0018] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 3 μm, such as figure 1 shown. Its specific surface area is 600m 2 / g, the graphene sphere wall is composed of four layers of graphene, such as figure 2 shown.

Embodiment 2

[0020] (1) The graphene oxide DMF solution with a concentration of 1 mg / mL was sprayed and dried to obtain graphene oxide microspheres. The atomization drying temperature is 100°C.

[0021] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 1000°C at 15°C / min and maintained for 10 minutes, and then heated to 3000°C at 3°C / min for graphitization.

[0022] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 6 μm. Its specific surface area is 1100m 2 / g.

Embodiment 3

[0024] (1) A graphene oxide methanol solution with a concentration of 10 mg / mL was sprayed and dried to obtain graphene oxide microspheres. The atomization drying temperature is 150°C

[0025] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 1300°C at 18°C / min and maintained for 10 minutes, and then heated to 3000°C at 5°C / min for graphitization.

[0026] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 3 μm. Its specific surface area is 1500m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com