Mesoporous silica nanoribbon material and production method thereof

A technology of mesoporous silica and nanobelts, applied in the direction of silica, silica, nanotechnology, etc., to achieve the effects of mild conditions, controllable morphology, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Dissolve 0.1 g of cetyltrimethylammonium bromide (CTAB) in 137 mL of deionized water until the solution is clear, then add 1.32 mL of ethyl acetate (EA) and continue to stir evenly;

[0022] b. Add 0.08 g of sodium dodecyl sulfate (SDS) to the above solution, with a molar ratio of 1 to CTAB, and stir well, then add 2.7 mL of ammonia (25-28 wt.%) and continue to stir evenly;

[0023] c. Finally, add 275 µL of tetraethylorthosilicate (TEOS) as the silicon source and continue the reaction for 20 hours. After the reaction is completed, the reactants are centrifuged, washed with deionized water and dried repeatedly, and the white powder obtained is It is a mesoporous silica nanobelt.

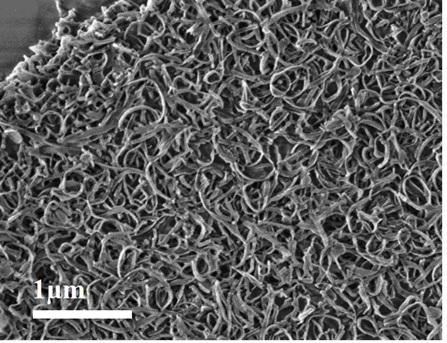

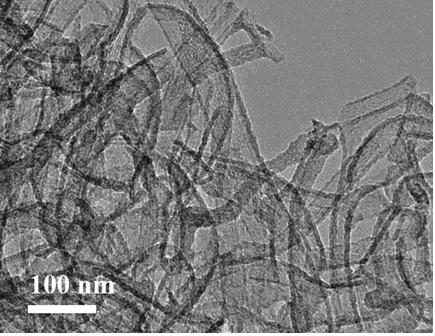

[0024] The physical properties of the obtained product were characterized, and some of the results are shown in the attached drawings. The obtained mesoporous silica product has a length between 1 µm and 1.5 µm, a width of about 45 nm, and a ribbon-like structure with curled edges. At the same t...

Embodiment 2

[0026] The preparation process and steps of this embodiment are basically the same as those of embodiment 1, except for step b:

[0027] The amount of sodium dodecyl sulfate (SDS) is 0.04 g.

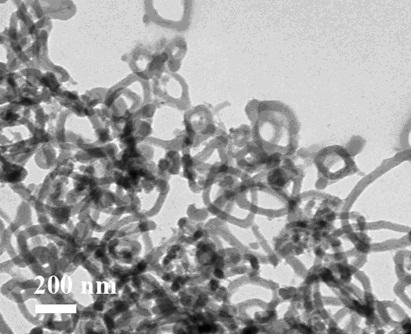

[0028] The results obtained are significantly different from those of Example 1 in terms of morphology and structure. The product obtained partially presents a closed ring structure, which is mainly composed of nanorods with a length of about 400 nm and a diameter of about 43 nm, and has good properties. The channel characteristics.

Embodiment 3

[0030] The preparation process and steps of this embodiment are basically the same as those of embodiment 1, except for step a:

[0031] The amount of ethyl acetate (EA) is 0.5 mL.

[0032] The results obtained are significantly different from those of Example 1. The obtained product has a layered structure with slight curls on the edges, but is relatively thick and has poor dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com