A continuous transmission quasi-non-diffracting wave microwave reactor

A microwave reactor, non-diffraction technology, applied in microwave heating, chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, etc., can solve difficult-to-process materials, insufficient utilization of microwave energy, slow processing speed, etc. problems, to achieve the effect of reducing the demand for output power, good reaction uniformity, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

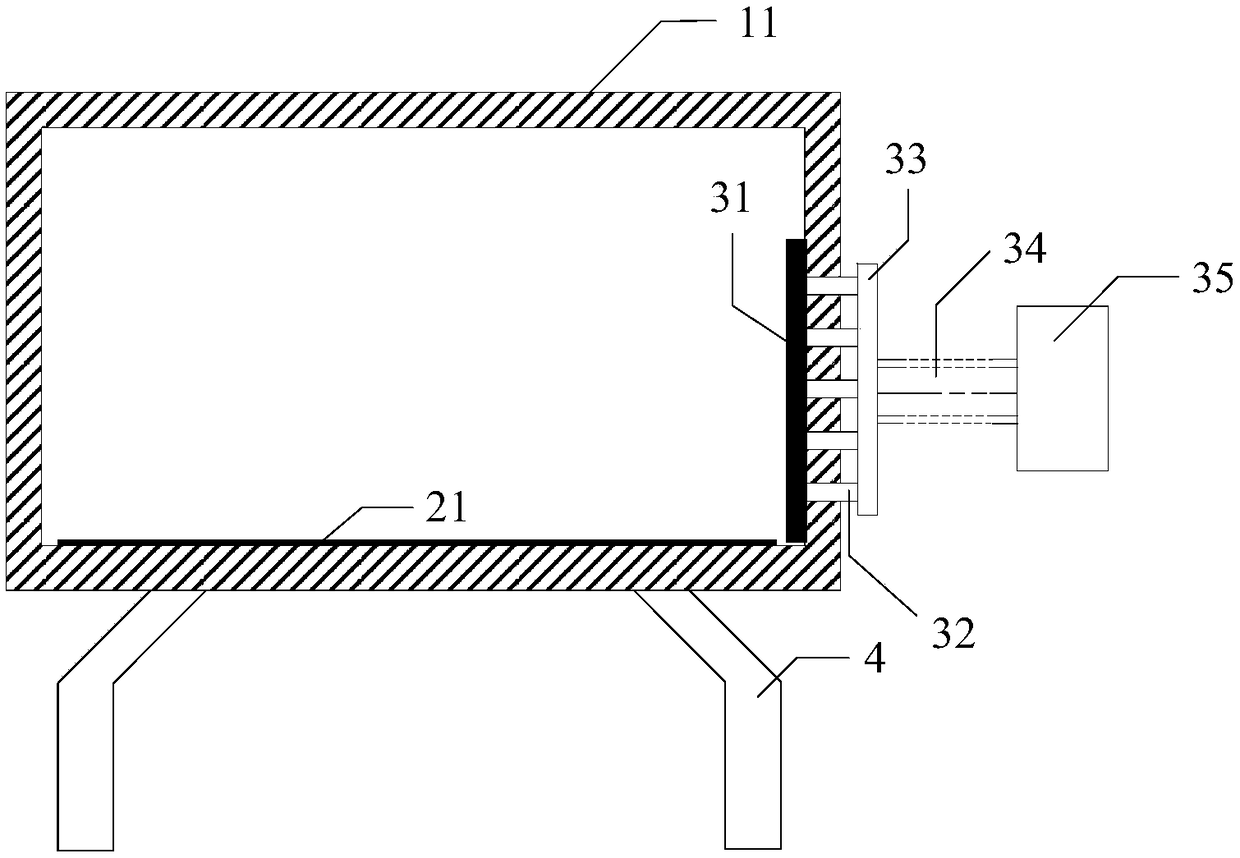

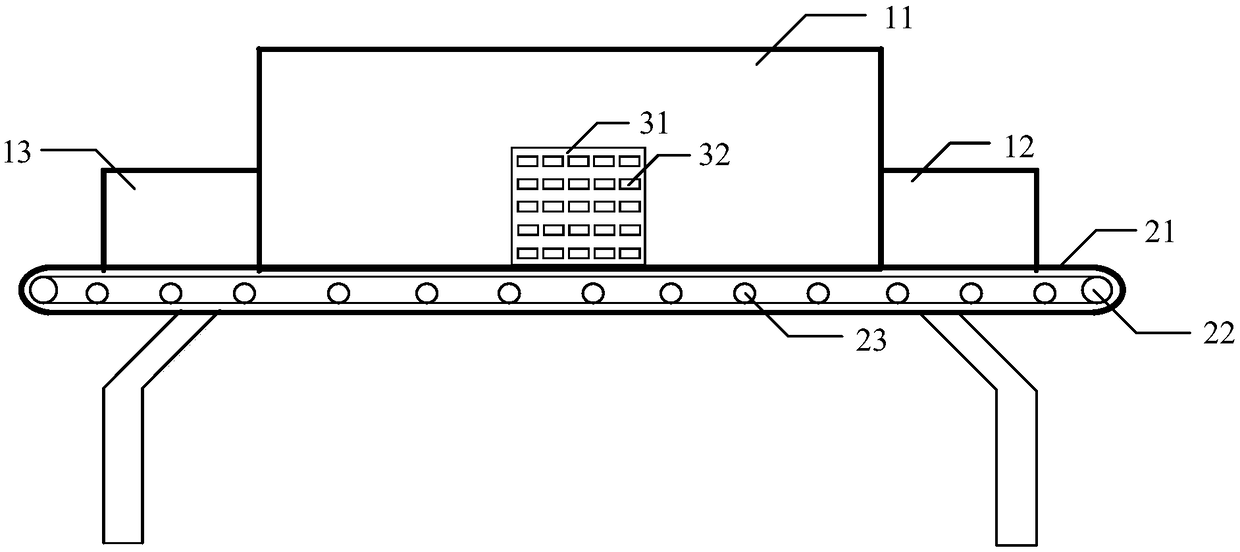

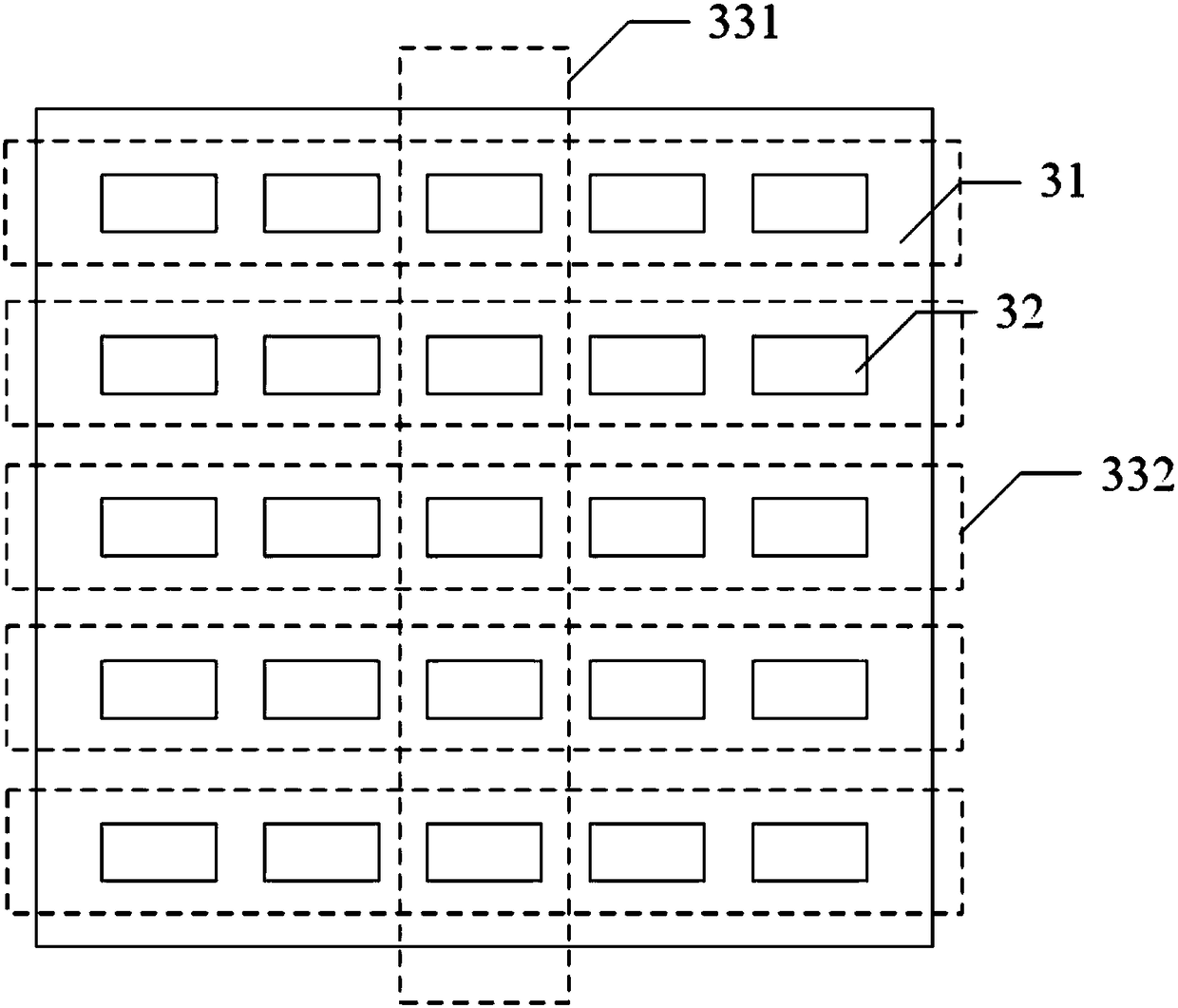

[0029]The present embodiment provides a continuous transmission quasi-non-diffracting wave microwave reactor, including a reaction device, a transmission device, a feeder and a support device; it is characterized in that the reaction device includes a cubic hollow metal cavity (11), which is arranged on a metal A cubic hollow metal inlet (12) extending outwards on one end surface of the cavity is not closed at both ends, and a corresponding outlet (13) of the same shape and size is arranged on the other end surface, and the inlet (12) and the outlet A thin absorbing material is attached to the inner wall of the mouth (13) to prevent microwave leakage; the transmission device includes: a conveyor belt (21), an adjustable speed motor and a power roller (22) and a supporting roller (23), and the conveyor belt passes through the metal cavity (11), the feed port (12) and the discharge port (13) are in contact with the bottom, the lower part of the conveyor belt is supported by a num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com