Method for using ethylenediamine cobalt (II)/transition metal to perform wet-process flue gas denitration

A transition group metal, ethylenediamine cobalt technology, applied in the field of electric power environmental protection, can solve the problems of reduced denitrification efficiency of absorption liquid, reduced catalytic oxidation performance, restricting the application of cobalt salt catalytic oxidation denitration technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

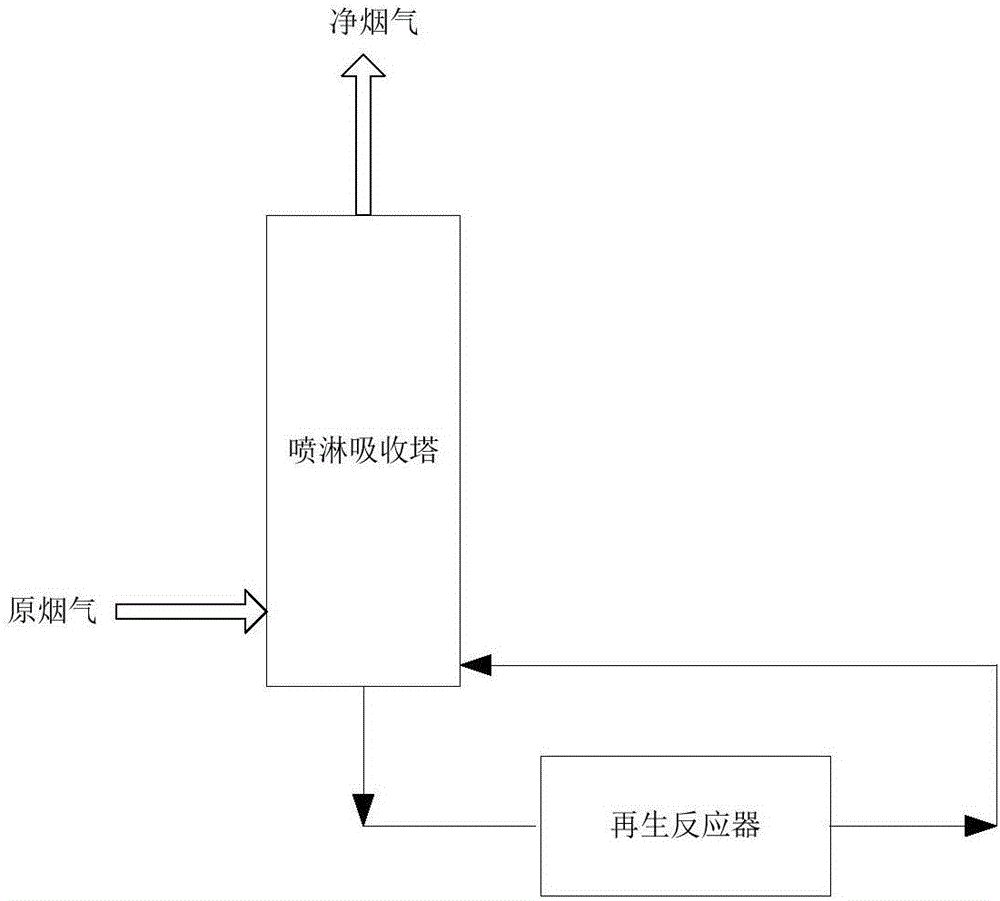

Method used

Image

Examples

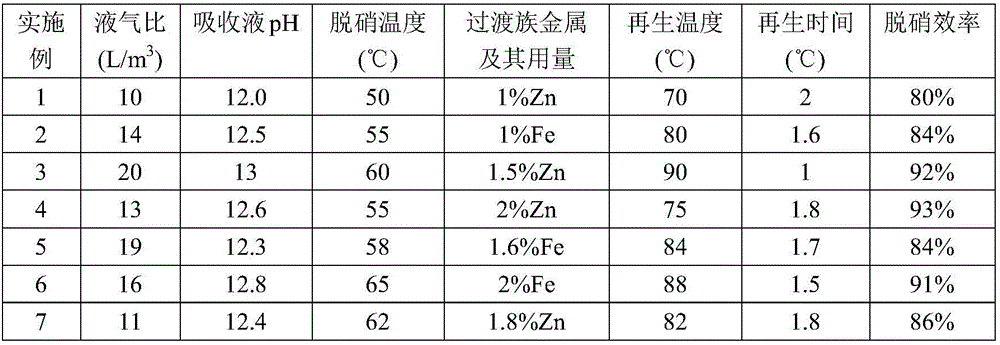

Embodiment 1

[0021] Let the original flue gas enter from the lower part of the spray absorption tower, and [Co(en) 3 ]Cl 2 Alkaline absorption liquid is in reverse contact from bottom to top, denitrification of flue gas is carried out at 50°C, and the net flue gas is discharged from the upper part of the absorption tower. When the denitrification efficiency decreases, the alkaline absorption liquid is discharged from the spray absorption tower and enters the regeneration reactor. After being treated with Zn powder at 70°C for 2 hours, the alkaline absorption liquid is regenerated, and the regenerated alkaline absorption liquid can be returned to the spray absorption tower to continue denitrification. Wherein, the liquid-gas ratio in the spray absorption tower is 10L / m 3 . The consumption of Zn powder is 1% of the quality of the alkaline absorption liquid to be treated in the regenerative reactor; 3 ]Cl 2 The pH of the aqueous solution was adjusted to 12.

Embodiment 2

[0023] Let the original flue gas enter from the lower part of the spray absorption tower, and [Co(en) 3 ]Cl 2Alkaline absorption liquid is in reverse contact from bottom to top, denitrification of flue gas is carried out at 55°C, and the net flue gas is discharged from the upper part of the absorption tower. When the denitrification efficiency decreases, the alkaline absorption liquid is discharged from the spray absorption tower and enters the regeneration reactor. After being treated with Fe powder at 80°C for 1.6h, the alkaline absorption liquid is regenerated, and the regenerated alkaline absorption liquid can be injected back into the spray absorption tower to continue denitrification. Wherein, the liquid-gas ratio in the spray absorption tower is 14L / m 3 . The amount of Fe powder or is 1% of the quality of the alkaline absorption liquid to be treated in the regenerative reactor; the alkaline absorption liquid is obtained by the following method: the [Co(en) 3 ]Cl 2 ...

Embodiment 3

[0025] Let the original flue gas enter from the lower part of the spray absorption tower, and [Co(en) 3 ]Cl 2 Alkaline absorption liquid is reversely contacted from bottom to top, flue gas denitrification is carried out at 60°C, and the net flue gas is discharged from the upper part of the absorption tower. When the denitrification efficiency decreases, the alkaline absorption liquid is discharged from the spray absorption tower and enters the regeneration reactor. After being treated with Zn powder at 90°C for 1 hour, the alkaline absorption liquid is regenerated, and the regenerated alkaline absorption liquid can be returned to the spray absorption tower to continue denitrification. Wherein, the liquid-gas ratio in the spray absorption tower is 20L / m 3 . The consumption of Zn powder is 1.5% of the quality of the alkaline absorption liquid to be treated in the regenerative reactor; 3 ]Cl 2 The pH of the aqueous solution was adjusted to 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com