A high-efficiency scr flue gas denitrification system applied to boiler burning inferior coal

A technology for boiler combustion and low-quality coal, applied in the field of flue gas denitration system of SCR process, can solve the problems of consumption, reduction of denitration efficiency, wear, etc., and achieve the effect of improving denitration reaction efficiency, improving reaction environment conditions, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

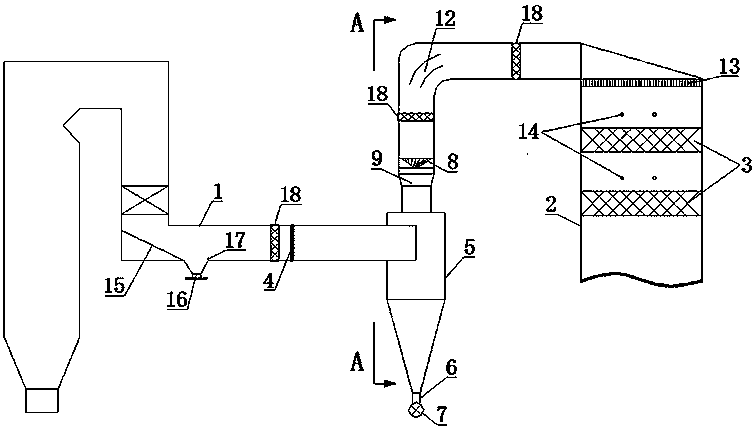

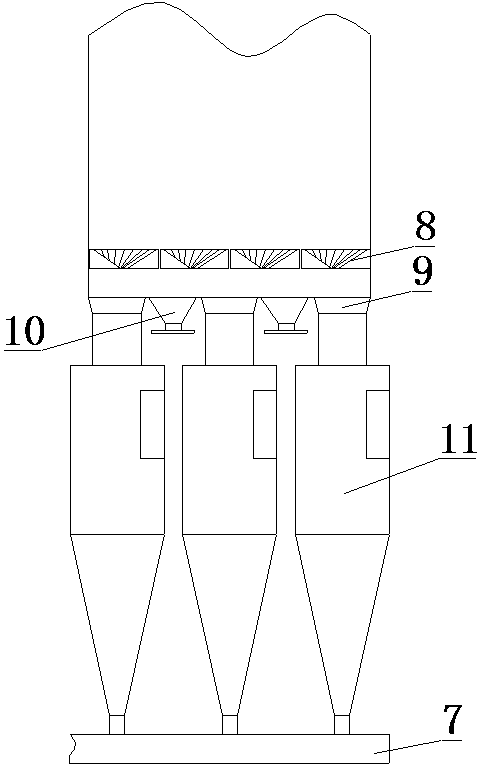

[0025] like figure 1 , figure 2 , image 3 As shown, a high-efficiency SCR flue gas denitrification system applied to boilers burning inferior coal types of the present invention includes an inlet flue 1 arranged behind the economizer and ammonia mixed with flue gas arranged behind the inlet flue 1 in sequence Unit, Reactor 2.

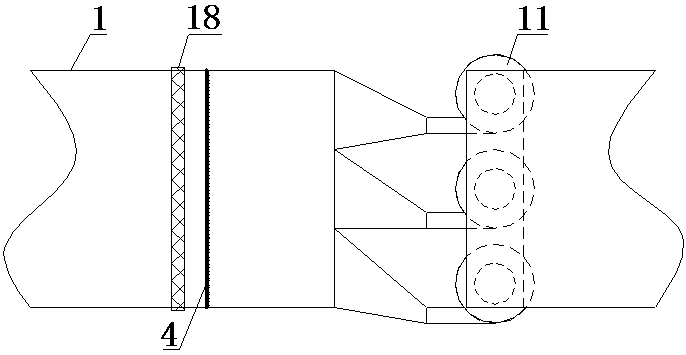

[0026] In the inlet flue 1, an anti-dusting device 15 is provided at the corner of the descending flue and the transverse flue, and a second ash unloading device 16 is provided below the anti-ashing device 15. Next to the second ash unloading device 16 A dust blocking device 17 is provided.

[0027] The ammonia and flue gas mixing unit includes an ammonia injection grid 4 for injecting reducing agent, a cyclone dust removal separation device 5 and a swirl plate devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com