A low-temperature high-activity flue gas denitrification catalyst and its preparation

A denitration catalyst and catalyst technology, applied in the field of environmental protection, can solve the problems of reduced denitration efficiency and unsuitability for industrial application, and achieve the effects of low production cost, high selectivity, and low denitration reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

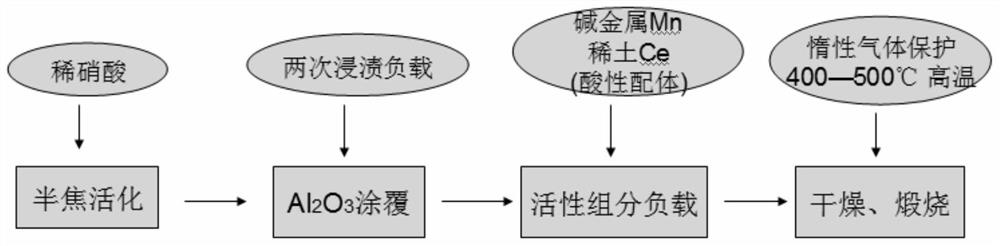

Method used

Image

Examples

Embodiment 1

[0068] Commercially available semi-coke is mechanically formed (purchased from the manufacturer: Derun Coal Preparation Equipment Co., Ltd. in Yulin, Shaanxi, the following examples are all the same, and it contains the following moisture in terms of mass: 17.96; ash content 20.12; volatile matter 29.19; fixed carbon 50.69; total sulfur 1.20), hole density 100-300 holes / inch 2 . Take 20% dilute nitric acid to impregnate the semi-coke carrier in excess, impregnate and activate for 2 hours, impregnate with ultrasonic (Ningbo Xinzhi Biotechnology Co., Ltd. Above, semi-coke after activation treatment is impregnated with Al in excess 2 o 3 Sol, pre-configured with a mass fraction of 1% Al 2 o 3 The solution was ultrasonically loaded for 2 hours, then dried at 110°C and fixed by calcining at 400°C for 3 hours; the soluble Mn salt was prepared as an aqueous solution with a mass fraction of 5% (calculated as manganese content), and the soluble Mn salt was manganese nitrate. The a...

Embodiment 2

[0071] Mechanically mold the commercially available semi-coke with a hole density of 100-300 holes / inch 2 , activated by 10% dilute nitric acid, ultrasonically impregnated at room temperature for 4 hours, and then dried at a constant temperature of 110°C for 2 hours; on this basis, the activated semi-coke was impregnated with Al 2 o 3 Sol, Al used 2 o 3 The mass fraction is 1.5%. After ultrasonic loading for 2 hours, it is dried at 110°C for 2h and then calcined at 400°C for 2h to fix; Ultrasonic impregnation at 30°C for 3h, drying at a constant temperature of 110°C for 2h and calcination at 450°C for 3h; the Ce(NO 3 ) 3 ·6H 2 O and the acidic ligand 1,4-phthalic acid used are pre-mixed uniformly at a molar ratio of 1:1.5 and configured to contain Ce(NO 3 ) 3 The mass fraction is 2% aqueous solution, citric acid adjusts the pH value to 6, and the load is impregnated by ultrasonic for 2 hours, dried at 110°C for 3 hours and calcined at 450°C for 2 hours; calcined in N 2...

Embodiment 3

[0074] Mechanically mold commercially available semi-coke with a hole density of 100-300 holes / inch 2 , take 25% dilute nitric acid to impregnate semi-coke in excess for activation, activate by ultrasonic impregnation at room temperature for 3 hours, and then dry at a constant temperature of 110°C for 2 hours; the activated semi-coke is excessively impregnated to load Al 2 o 3 Sol, Al used 2 o 3 The mass fraction is 2%. After ultrasonic loading for 2 hours, it is dried at 110°C for 3 hours and fixed at 450°C for 3 hours; the carrier is immersed in a soluble manganese nitrate solution, wherein the solution is a pre-configured The aqueous solution with a fraction of 8% was ultrasonically impregnated at room temperature at 30°C for 2h on the basis of the above, dried at a constant temperature of 110°C for 3h and calcined at 350°C for 3h to fix; the Ce(NO 3 ) 3 ·6H 2 O and the acidic ligand 1,4-phthalic acid used are mixed uniformly at a molar ratio of 1:2.0, and configured t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com