Inverted A2/O+ composite MBR sewage treatment device and treatment method thereof

A sewage treatment device and composite technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low denitrification efficiency, achieve large contact area and easy installation The effect of simple disassembly and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

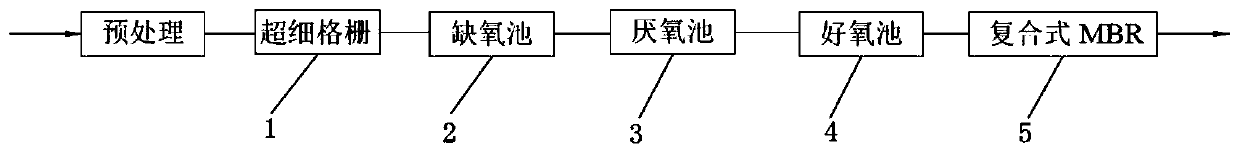

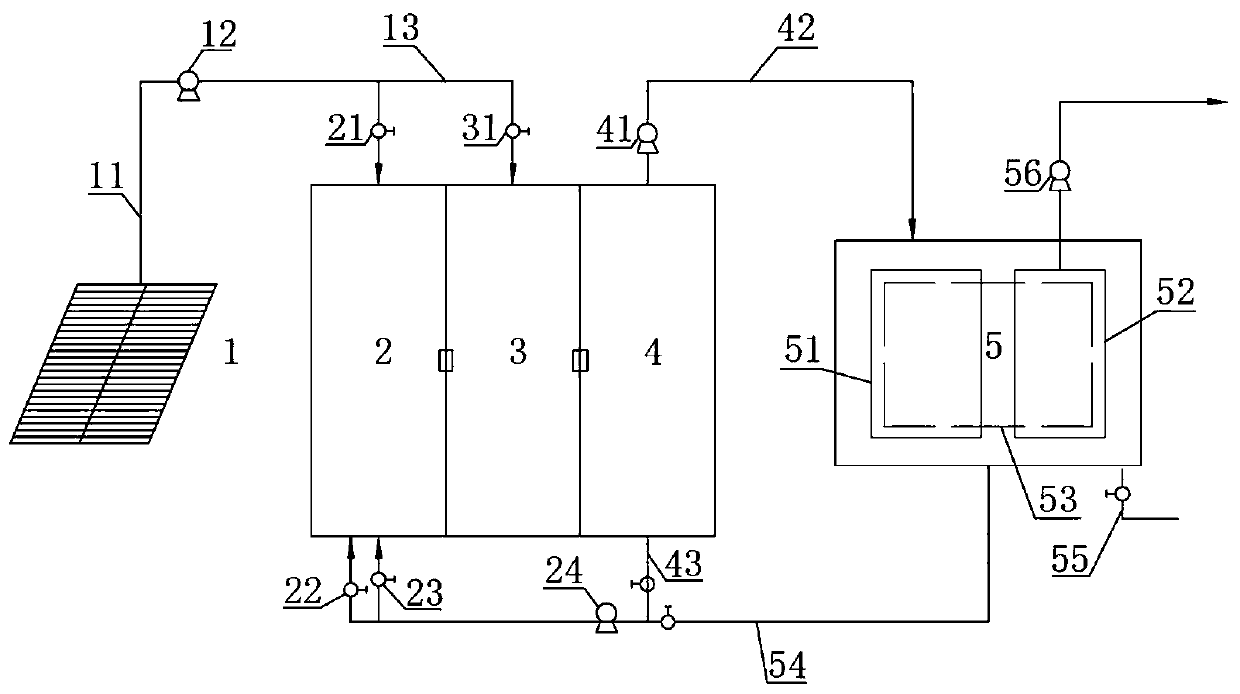

[0039] Such as figure 1 As shown, an inverted A 2 / O+ compound MBR device, including superfine grid 1, anoxic pool 2, anaerobic pool 3, aerobic pool 4 and compound MBR pool 5 arranged in sequence according to the water flow direction.

[0040] Such as figure 2 As shown, the ultra-fine grids 1 are arranged in parallel, and the distance between the two grids is 0.1 mm. The ultra-fine grids 1 are composed of grid bars, and the distance between the grid bars is 0.2-2 mm, and are used to filter finer particles in the pretreatment water.

[0041] The ultra-fine grid 1 is connected to the anoxic pool 2 and the anaerobic pool 3 through the water inlet pipe 11. The water inlet pipe 11 is provided with a multi-point water inlet pipe 13, and the sewage is respectively connected to the anoxic pool 2 and the anaerobic pool through the multi-point water inlet pipe 13. Pond 3; Multi-point water inlet pipe 13 is connected to the pipeline of anoxic pool 2 and is provided with anoxic pool wa...

Embodiment 2

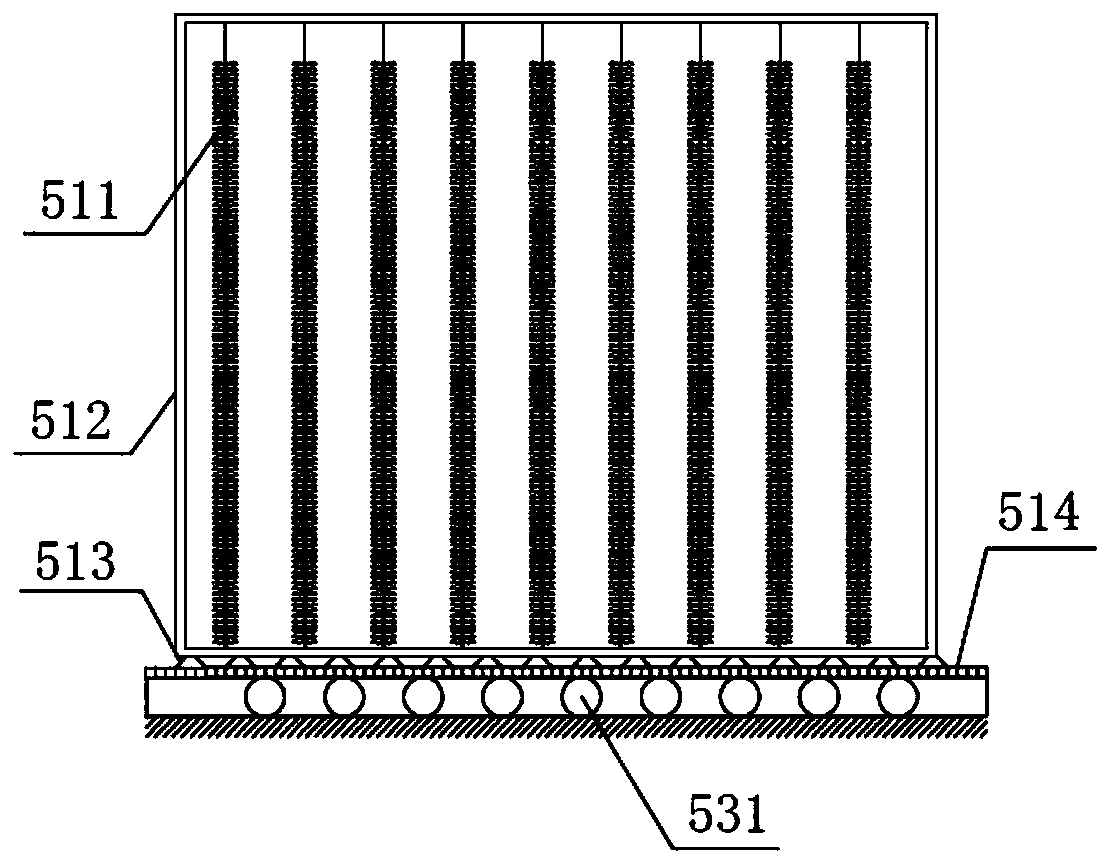

[0061] Utilize the device and method of embodiment 1 to process the domestic sewage after pretreatment, specific process conditions: hydraulic retention time 7.5h, MBR tank hydraulic retention time 1.5h, nitrifying liquid reflux ratio is 120%; The reflux of activated sludge The ratio is 180%; the diameter of the three-dimensional elastic filler unit of the composite MBR pool is 200mm, and the filler spacing is 80mm; the flat membrane is selected, and the design margin of the membrane flux is increased by 30%; Component processing volume is less than 1.2m 3 / hr; Choose a perforated aeration tube with a diameter of 20mm, with a hole of 2mm, a hole spacing of 100mm, a steam-water ratio of 24:1, and control of dissolved oxygen at 3-5mg / L.

[0062] The scale of the sewage plant is 20,000 tons / day, and the average influent COD is 352.5mg / L, BOD 5 124.7mg / L, ammonia nitrogen 25.6mg / L, total nitrogen 32.2mg / L, total phosphorus 4.1mg / L.

[0063] The effluent water quality is COD 20....

Embodiment 3

[0065] The influent water quality of a sewage plant is: average COD 422.4mg / L, BOD 5 141.9mg / L, ammonia nitrogen 28.3mg / L, total nitrogen 36.2mg / L, total phosphorus 5.6mg / L.

[0066] The original sewage treatment process of the sewage plant is A 2 / O+MBR process, the treatment scale is 10,000 tons / day, the hydraulic retention time is 9h, the hydraulic retention time of the MBR tank is 2h, the reflux ratio of nitrification liquid is 200%, the activated sludge reflux ratio is 200%, the hollow fiber membrane is selected, and a single membrane module is used for treatment Volume below 1.0m 3 / hr, 18mm diameter aeration perforated tube, 1.8mm perforation, 150mm perforation spacing, 24:1 soda water ratio. After being treated by the original sewage treatment process of the sewage plant, the effluent quality is COD 50.5mg / L, BOD 5 10.4mg / L, ammonia nitrogen 4.8mg / L, total nitrogen 13.5mg / L, total phosphorus 0.48mg / L, meeting the first-class a emission standard.

[0067] Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com