Coal economizer bypass flue outlet high-temperature and low-temperature flue gas flow mixing device

A technology of bypass flue and economizer, applied in the field of flue gas denitrification, can solve the problems of flue gas temperature field variation at catalyst inlet, denitrification efficiency reduction, catalyst activity decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

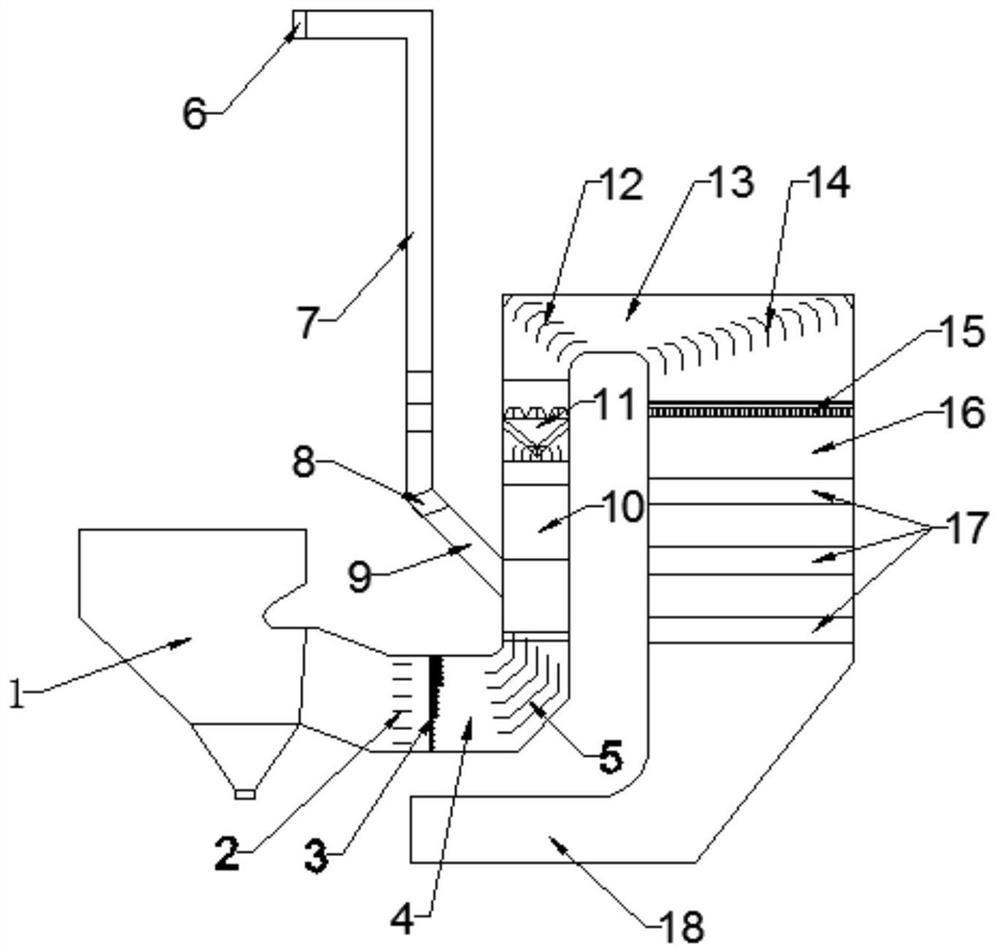

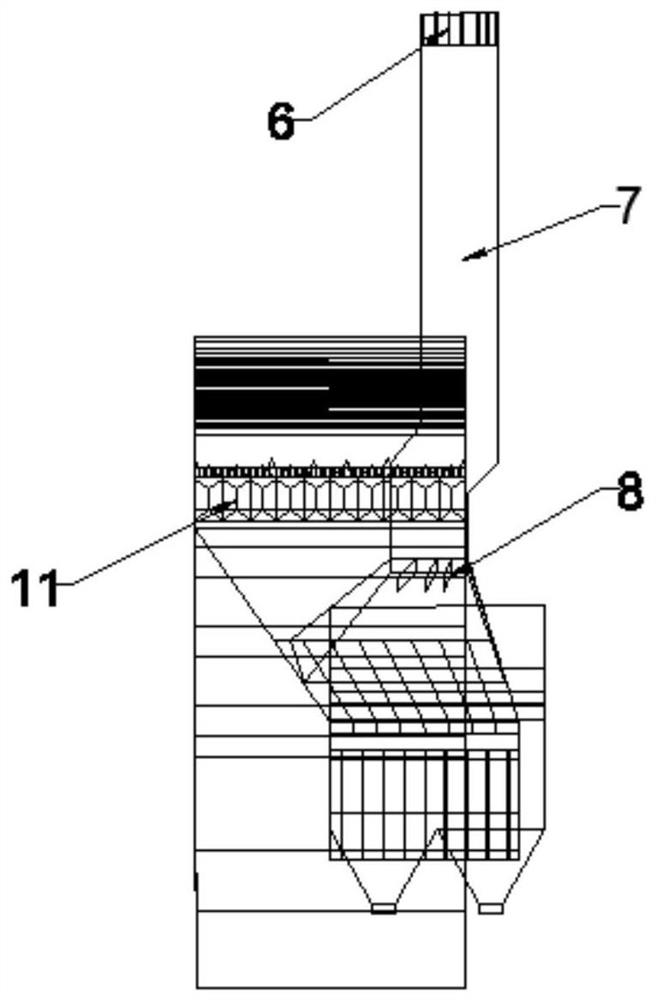

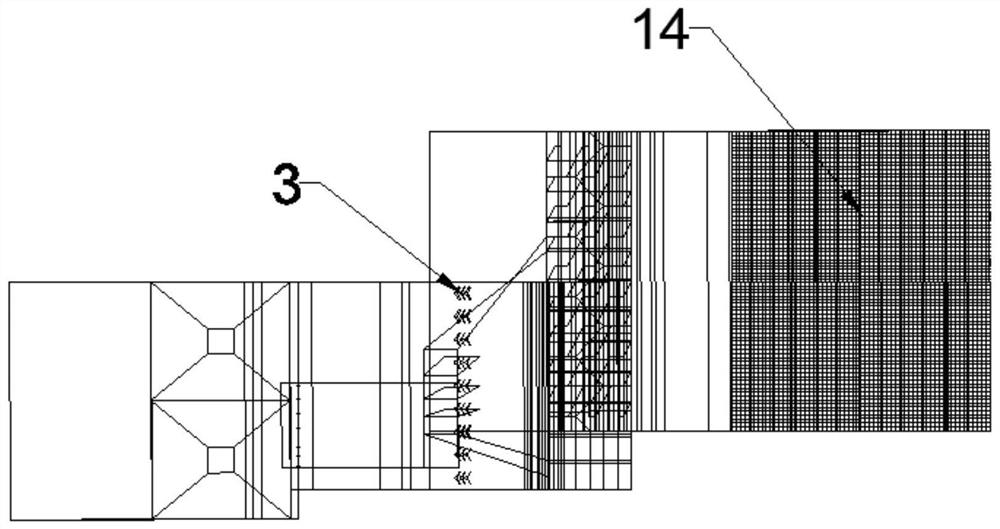

[0031] Such as Figure 1-6 and Figure 8 As shown, a high and low temperature flue gas mixing device at the outlet of the bypass flue of the economizer has two groups, which are the high and low temperature flue gas mixing device A at the outlet of the bypass flue of the economizer and the high temperature flue gas at the outlet of the bypass flue of the economizer. The low-temperature flue gas mixing device B, both of which are connected to the boiler in front and arranged symmetrically around the boiler, taking one of the high-low temperature flue gas mixing devices at the outlet of the economizer bypass flue as an example, the structure is described as follows:

[0032]Each group of economizer bypass flue outlet high and low temperature flue gas mixed flow device includes economizer bypass flue and SCR denitrification device connected, including: economizer outlet flue 1, main baffle door 2 , SCR ammonia injection system 3, SCR denitrification device inlet horizontal flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com