Ultrasonic non-destructive testing device for pipeline defects

A non-destructive testing and ultrasonic technology, applied in the field of ultrasonic testing, can solve problems such as missing defects, and achieve the effect of strong waterproof ability and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

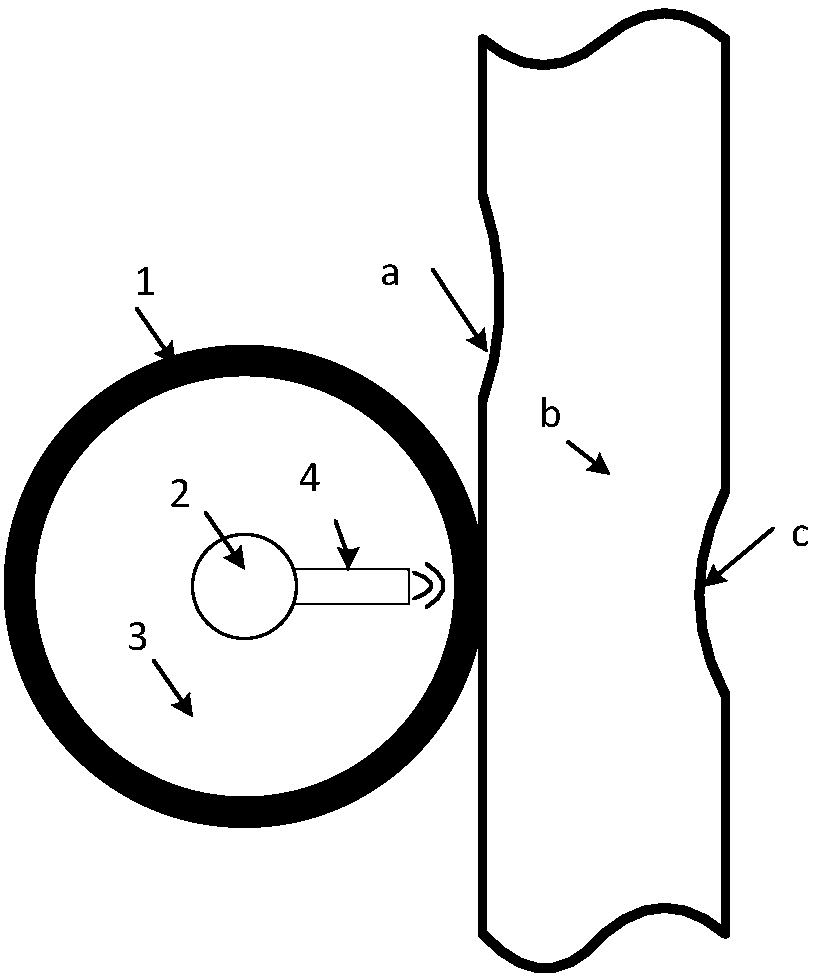

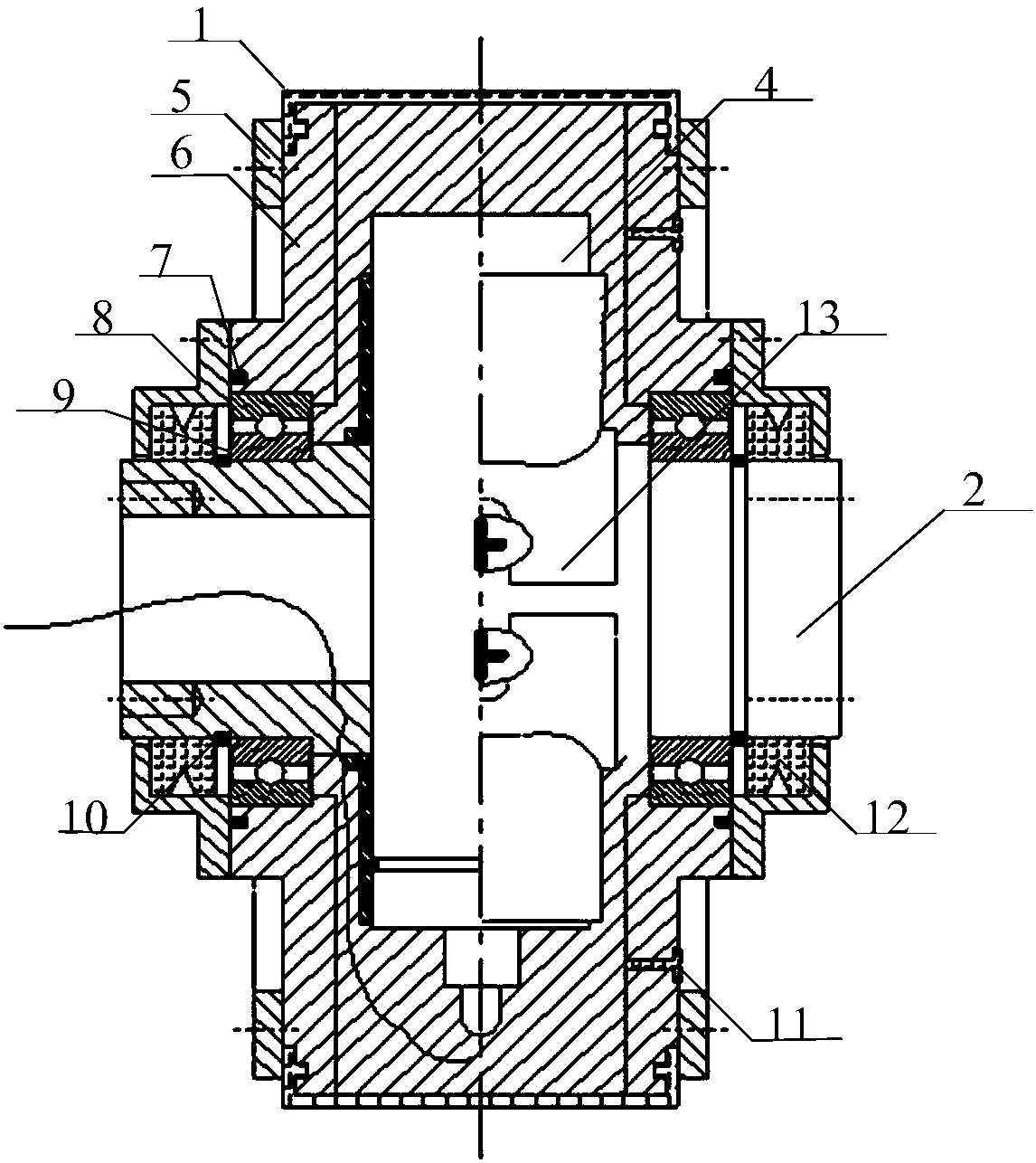

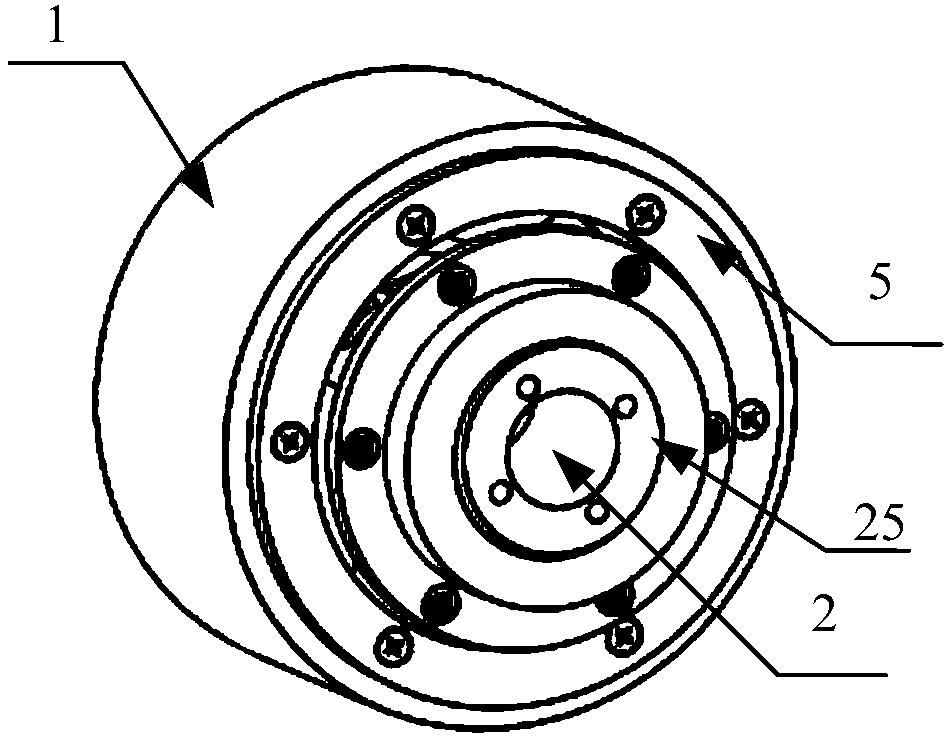

[0043] The invention provides an ultrasonic nondestructive testing device for pipeline defects, the principle of which is as follows figure 1 shown. Utilize the ultrasonic echo time difference to quantitatively calculate the relative wall thickness of the pipe wall b to detect the defect of the pipe wall b. When the ultrasonic wave emitted by the ultrasonic transducer 4 propagates in the waveguide, the boundary of the waveguide will affect the propagation of the ultrasonic wave. Using this characteristic , the relative wall thickness of the pipe wall b at this position can be calculated through the time difference of the echo signal of the ultrasonic wave emitted by the ultrasonic transducer 4 . Such as figure 1 As shown, the ultrasonic transducer 4 is fixed on the wheel shaft 2, the rubber wheel 1 and the wheel shaft 2 are connected by an annular f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com