Super-large-diameter coal seam drilling pipe insertion goaf gas extraction technology

A super-large-diameter, large-diameter technology, which is applied in the field of gas technology in super-large-diameter coal seam drilling and intubation to extract gobs, and can solve problems such as difficult management, gas exceeding the limit, and air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

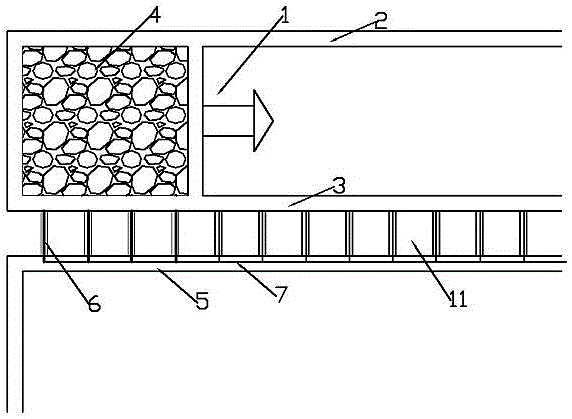

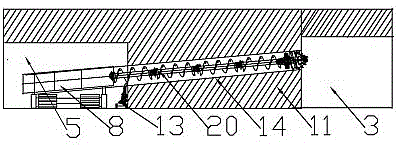

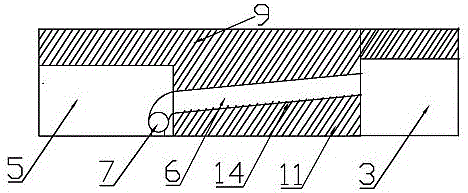

[0020] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a super-large-diameter coal seam borehole intubation pipe drainage gob gas process, characterized in that: ① A measure lane 5 is constructed after a protective coal pillar 11 is left on the side of the return airway 3, and a scraper conveyor is installed in the measure lane 5 13. Drill several large-diameter boreholes 6 on the protective coal pillar 11 left in the coal seam 9 with a large-diameter auger drilling machine to the upper corner of the air return roadway 3 from the measure lane 5, and insert them into the large-diameter borehole 6. The drilling casing 14 is connected to the drainage pipeline 7 to perform gas drainage for the gas in the goaf 4 .

no. 2 example

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a super-large-diameter coal seam borehole intubation pipe drainage gob gas process, characterized in that: ① A measure lane 5 is constructed after a protective coal pillar 11 is left on the side of the return airway 3, and a scraper conveyor is installed in the measure lane 5 13. Drill several large-diameter boreholes 6 on the protective coal pillar 11 left in the coal seam 9 with a large-diameter auger drilling machine to the upper corner of the air return roadway 3 from the measure lane 5, and insert them into the large-diameter borehole 6. The drilling casing 14 is connected to the drainage pipeline 7 to perform gas drainage for the gas in the goaf 4 .

[0023] Among them: ②When the current mining face 1 is finished, the measure lane 5 is set as the air inlet roadway 2, all the current large-diameter boreholes 6 are closed, and a return air roadway 3 is constructed, and the step ① is repeated to realiz...

no. 3 example

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a super-large-diameter coal seam borehole intubation pipe drainage gob gas process, characterized in that: ① A measure lane 5 is constructed after a protective coal pillar 11 is left on the side of the return airway 3, and a scraper conveyor is installed in the measure lane 5 13. Drill several large-diameter boreholes 6 on the protective coal pillar 11 left in the coal seam 9 with a large-diameter auger drilling machine to the upper corner of the air return roadway 3 from the measure lane 5, and insert them into the large-diameter borehole 6. The drilling casing 14 is connected to the drainage pipeline 7 to perform gas drainage for the gas in the goaf 4 .

[0026] Among them: ②When the current mining face 1 is finished, the measure lane 5 is set as the air inlet roadway 2, all the current large-diameter boreholes 6 are closed, and a return air roadway 3 is constructed, and the step ① is repeated to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com