A reinforcement method for fire-damaged bridges

A fire-burning and bridge technology, applied in bridge reinforcement, bridges, bridge materials, etc., can solve the problems of affecting the speed of operation, affecting the bearing capacity, weakening the bending stiffness of beams, etc., to solve the problem of vertical stiffness and transverse integrity, and improve the vertical Effects on stiffness and integrity, restoration of operational load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

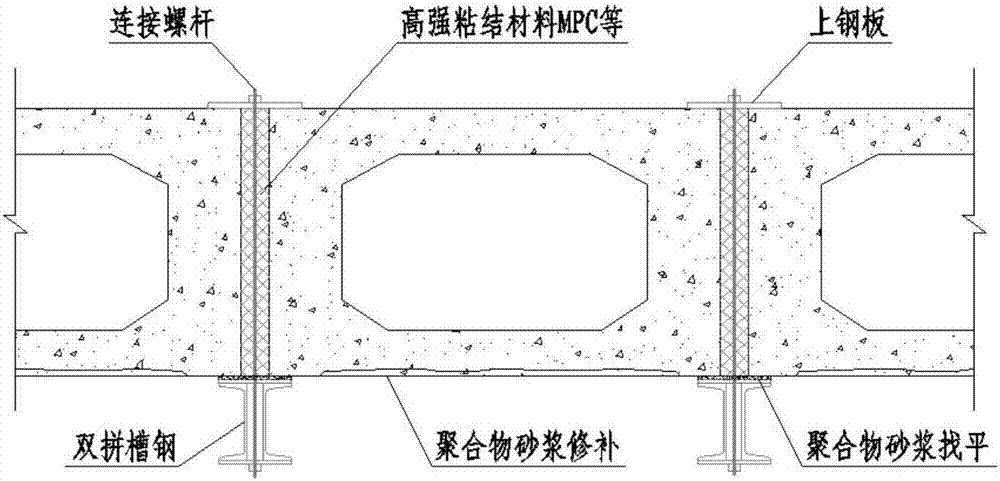

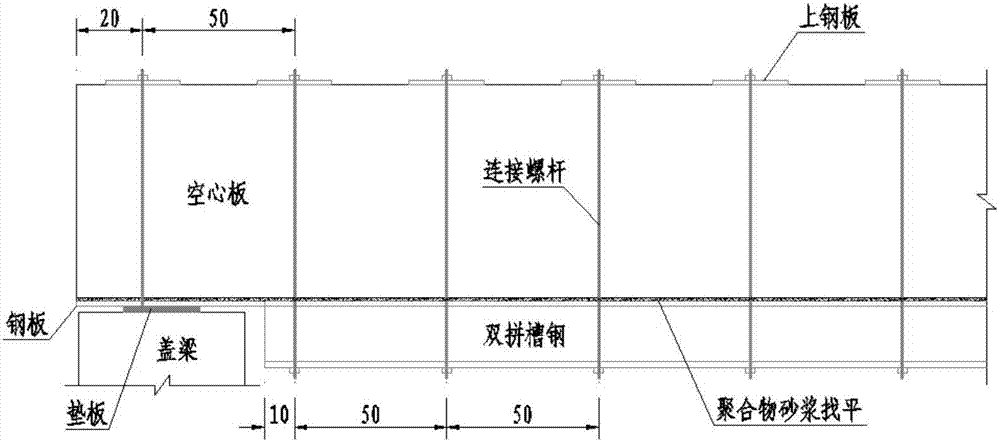

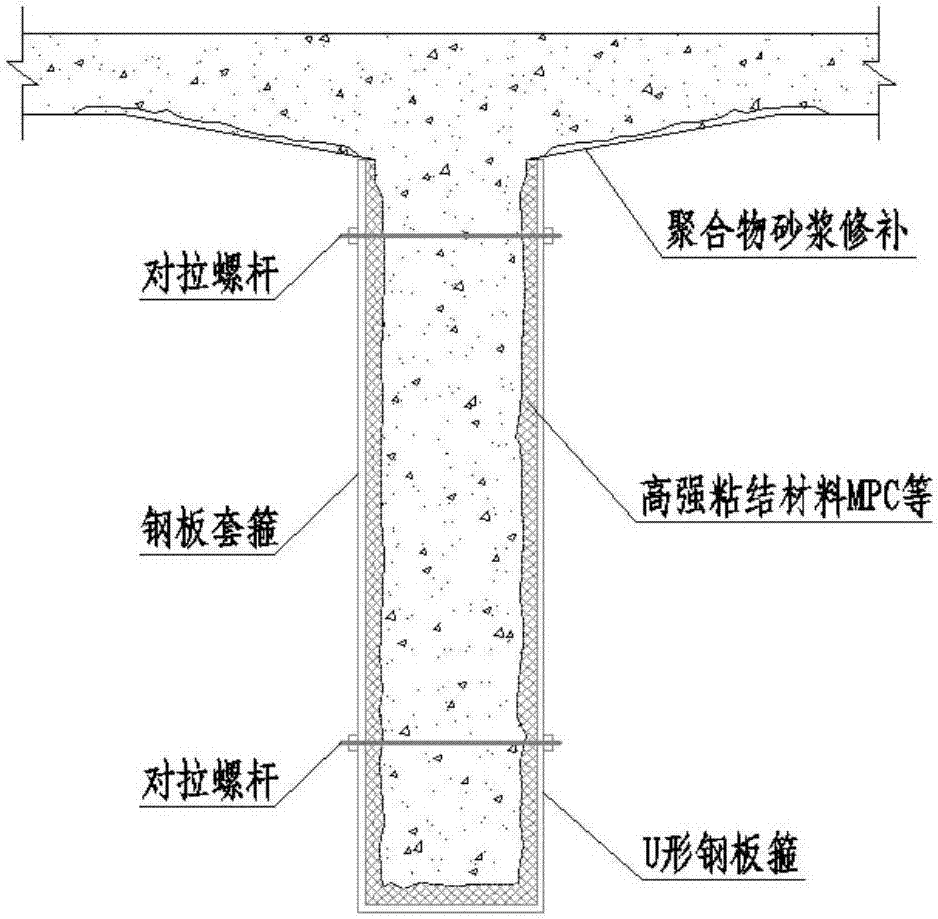

[0040] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. This specific embodiment provides a preferred reinforcement method for fire-damaged bridges. However, the following technical features can be combined accordingly on the premise that there is no conflict with each other.

[0041] In this embodiment, the bridge to be reinforced is formed by erecting hollow slab girders, T girders or small box girders. The lower part of the bridge was burned, causing the bottom plate of the hollow slab girder or the web, bottom plate and top plate of the T-beam or small box girder to be damaged to varying degrees. Adopt reinforcement method of the present invention to reinforce it, specifically as follows:

[0042] 1. Assess the degree of component damage

[0043] First of all, according to the relevant provisions of the "Building Structure Appraisal Standard after Fire", the damage of the fire-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com