Bridge damping support and damping method

A damping and bridge technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large installation size and space occupancy, easy damage, large consumption of processing materials, etc., to solve the problem of connection strength, uniform middle section, The effect of preventing bridge beams from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

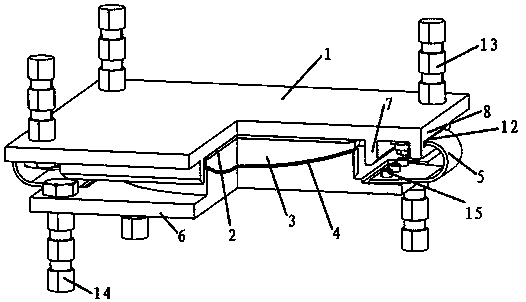

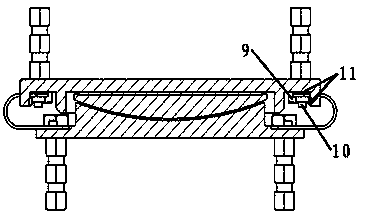

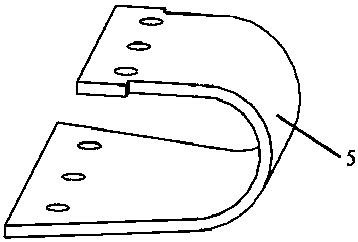

[0022] Please refer to Figure 1 to Figure 4 , a bridge damping support, including an upper seat plate 1, a flat slide plate 2, a spherical crown lining plate 3, a spherical slide plate 4, a variable-section steel damping element 5, a lower seat plate 6, a limit stop 7, and a groove stop 8 , Shear block 9, connecting bolt two 10, rubber block 11, anti-skid strip 12, upper anchor rod 13, lower anchor rod 14, connecting bolt one 15.

[0023] The upper seat plate is connected to the upper anchor rod, and the two ends of the upper seat plate are provided with a limit stopper and a groove-shaped stopper for limiting the variable-section steel damping element. The groove-shaped stopper is adjacent to the end surface of the upper seat plate. There is a groove, the upper part of the variable-section steel damping element is located in the groove of the groove block, and the upper end surface of the variable-section steel damping element is adjacent to the limit block. The lower seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com