Porous polymer material and preparation method thereof

A technology of porous polymers and prepolymers, applied in the field of porous polymer materials and their preparation, epoxy resin/bismaleimide/polyphenylene ether porous structure polymer materials and their preparation, can solve the problem of solvent or Problems such as complex process, gap size and difficulty in control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 27g of epoxy resin (E-51), 27g of N,N'- (4,4'-methylenediphenyl) bismaleimide (BMI) and 20.25g of polyphenylene ether (PPO*MX9000- 111) Mix, stir and heat at 150°C for about 70min, the obtained epoxy resin / bismaleimide / polyphenylene ether prepolymer is then vacuumed at 150°C until no bubbles are generated, and then according to 180°C / 2h+200°C / 2h+220°C / 2h for curing treatment, epoxy resin / bismaleimide / polyphenylene ether resin porous polymer material can be obtained.

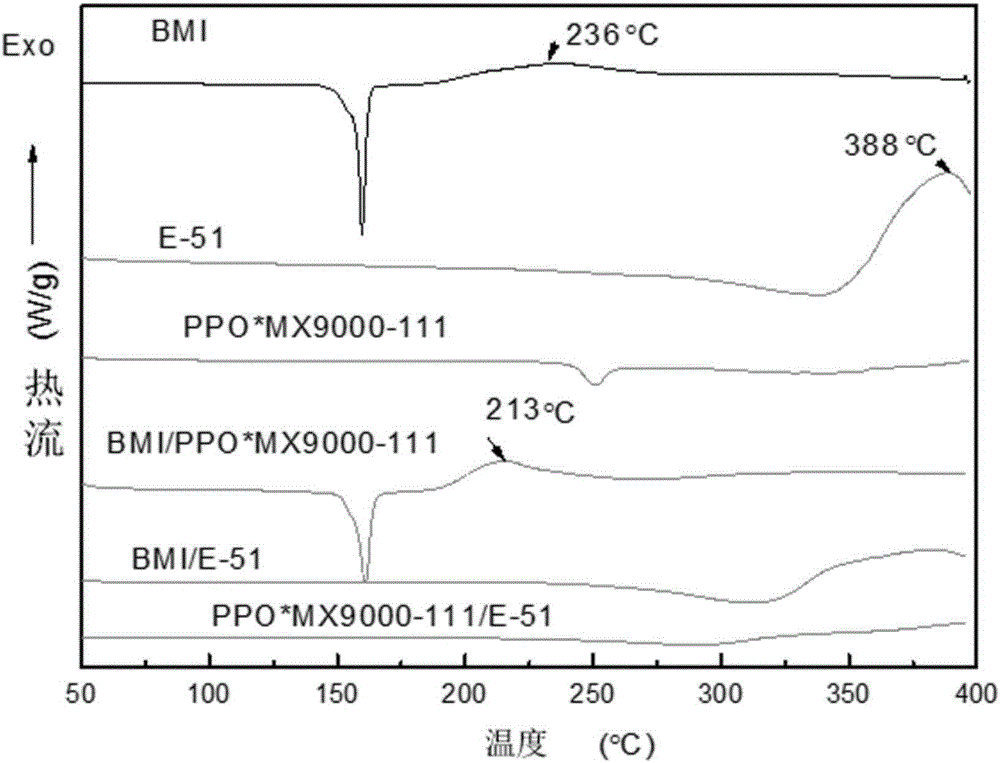

[0026] figure 1 It is the differential scanning calorimetry (DSC) method curve of epoxy E-51, BMI, PPO* MX9000-111 and different component mixtures. from figure 1 It can be seen that BMI can undergo self-polymerization, and its reaction exothermic peak temperature is 236°C. Epoxy resin E-51 partially decomposes at 350°C, and self-polymerization can occur at 388°C. The melting temperature of PPO* MX9000-111 The reaction temperature of the mixture of BMI and PPO*MX9000-111 is 213℃, the reaction tempe...

Embodiment 2

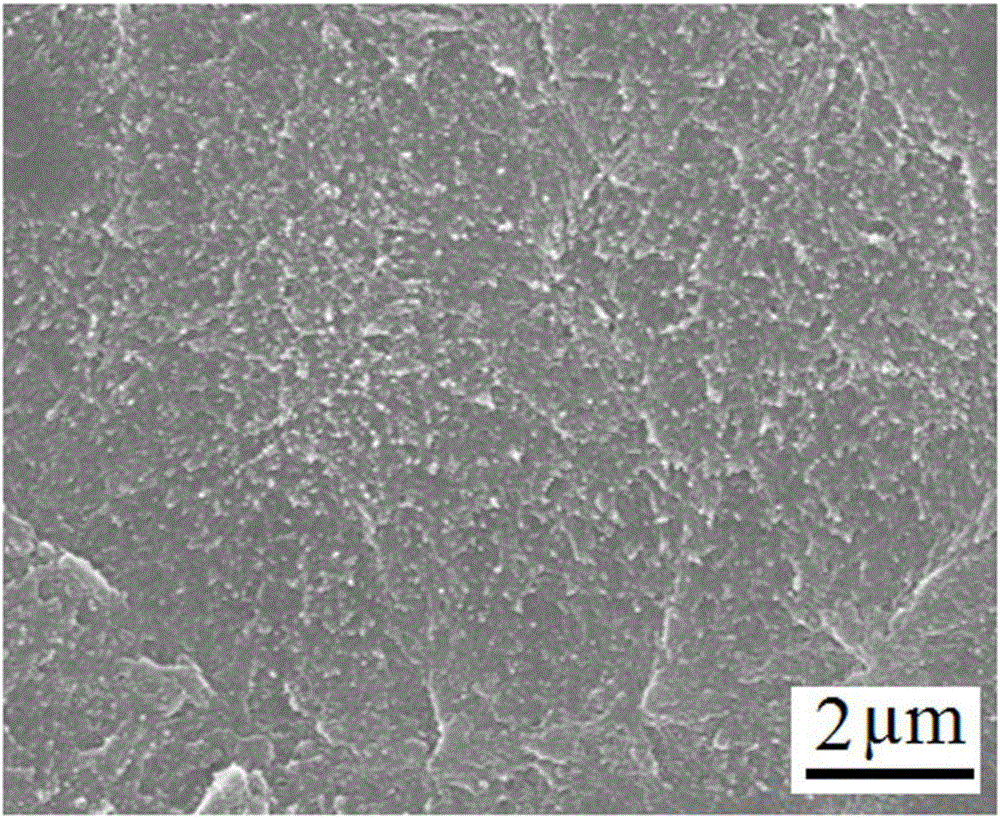

[0029] Mix 27g of epoxy resin (E-51), 27g of N,N'- (4,4'-methylenediphenyl) bismaleimide (BMI) and 13.5g of polyphenylene ether (PPO*MX9000- 111) Mix, stir and heat at 150°C for about 70min, the obtained epoxy resin / bismaleimide / polyphenylene ether prepolymer is then vacuumed at 150°C until no bubbles are generated, and then according to 180°C / 2h+200°C / 2h+220°C / 2h for curing treatment, epoxy resin / bismaleimide / polyphenylene ether resin porous polymer material can be obtained. image 3It is the SEM picture of the cross-section of the porous polymer material in Example 2. It can be seen from the figure that there are obvious pores in the material. The relevant material performance data are shown in Table 1.

Embodiment 3

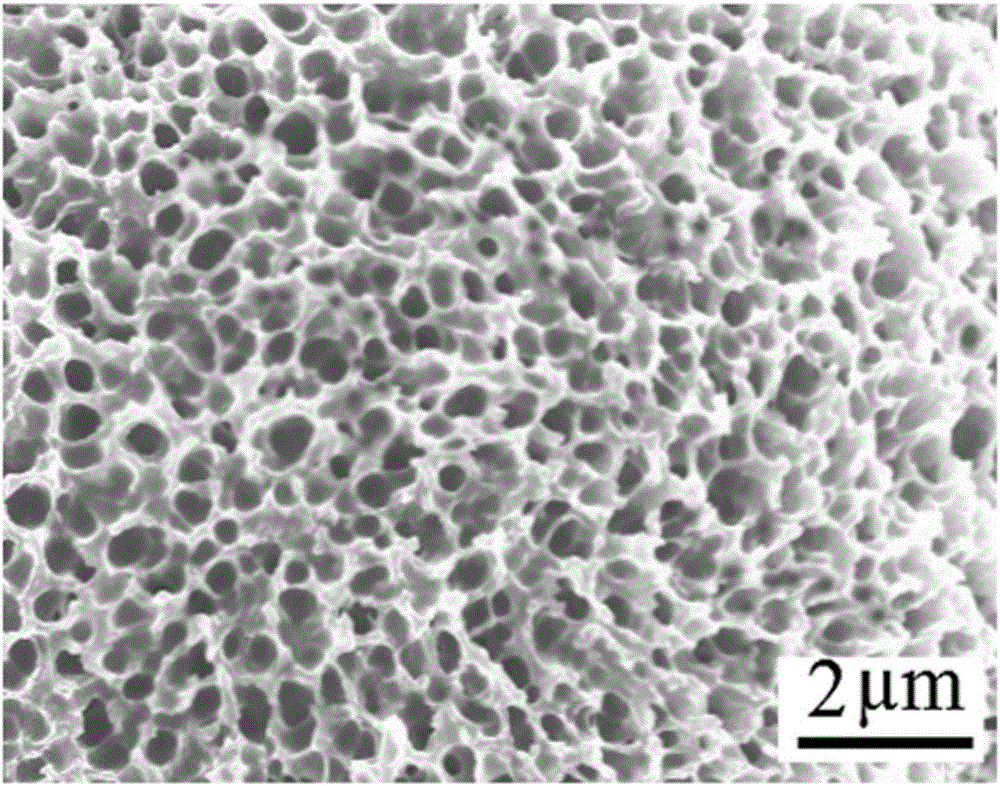

[0031] Mix 32g of epoxy resin (E-51), 32g of N,N'-(4,4'-methylenediphenyl) bismaleimide and 8g of polyphenylene ether (Noryl* SA9000), at 155℃ Stir and heat for about 70 minutes to obtain the epoxy resin / bismaleimide / polyphenylene ether prepolymer, then vacuumize at 155°C until no bubbles are generated, and then follow the steps of 180°C / 2h+200°C / 2h+ Curing treatment at 220°C / 2h can obtain epoxy resin / maleimide / polyphenylene ether resin porous polymer material. Figure 4 It is the SEM picture of the cross-section of the porous polymer material in Example 3. It can be seen from the figure that there are obvious pores in the material. The relevant material performance data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com