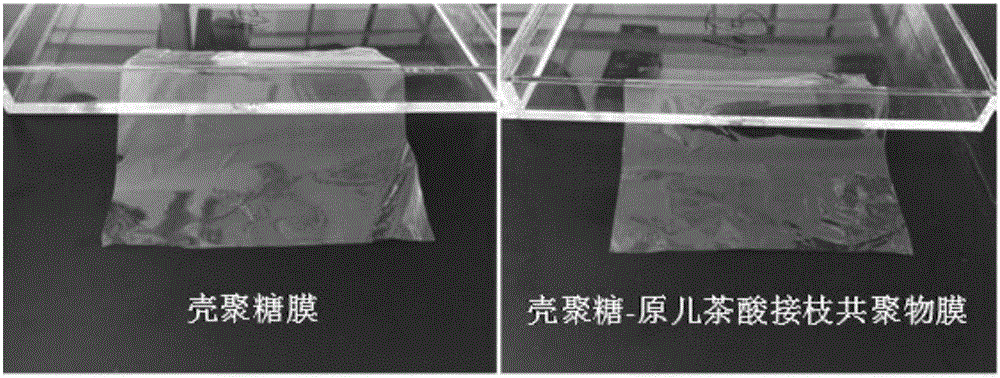

Preparation method of chitosan-protocatechuic acid graft copolymer film

A technology of graft copolymer and protocatechuic acid, which is applied in the field of preparation of chitosan-protocatechuic acid graft copolymer film, can solve unfavorable large-scale production application, low mechanical strength of plastic wrap, and antioxidant activity Low-level problems, to achieve the effect of simple and easy operation in the film-making process, improved mechanical properties and physical and chemical properties, and low transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of chitosan-protocatechuic acid graft copolymer film:

[0032] (1) Take by weighing 1.22g chitosan and be dissolved in 25mL 0.5% acetic acid solution, stir magnetically until completely dissolving, obtain chitosan solution; Take by weighing 5.8g protocatechuic acid and dissolve in 5mL dehydrated alcohol, obtain protocatechuic acid Catechin solution;

[0033] (2) Add 7.2g of EDC, protocatechuic acid solution, and 4.3g of NHS into a 20mL MES buffer reactor in sequence, and control the pH range to 6; then place it in an ice-water bath, and react with magnetic stirring for 1h;

[0034] (3) Add the fully dissolved chitosan solution into the reactor, and react for 24 hours at room temperature and normal pressure;

[0035] (4) Put the reaction solution into a dialysis bag, dialyze with tap water for 48 hours, and then dialyze with deionized water for 24 hours. After the dialysate is freeze-dried, the chitosan-protocatechuic acid graft copolymer is obta...

Embodiment 2

[0044] The preparation process of chitosan-protocatechuic acid graft copolymer film:

[0045] (1) Take by weighing 1.22g chitosan and be dissolved in 25mL 0.5% acetic acid solution, stir magnetically until completely dissolving, obtain chitosan solution; Take by weighing 5.8g protocatechuic acid and dissolve in 5mL dehydrated alcohol, obtain protocatechuic acid Catechin solution;

[0046] (2) Add 7.2g of EDC, protocatechuic acid solution, and 4.3g of NHS into a 20mL MES buffer reactor in sequence, and control the pH range to 5.5; then place it in an ice-water bath, and react with magnetic stirring for 1h;

[0047] (3) Add the fully dissolved chitosan solution into the reactor, and react for 12 hours at 20°C;

[0048] (4) Put the reaction solution into a dialysis bag, dialyze with tap water for 48 hours, and then dialyze with deionized water for 24 hours. After the dialysate is freeze-dried, the chitosan-protocatechuic acid graft copolymer is obtained, which is a purple-red sa...

Embodiment 3

[0057] The preparation process of chitosan-protocatechuic acid graft copolymer film:

[0058] (1) Take by weighing 1.22g chitosan and be dissolved in 25mL 0.5% acetic acid solution, stir magnetically until completely dissolving, obtain chitosan solution; Take by weighing 5.8g protocatechuic acid and dissolve in 5mL dehydrated alcohol, obtain protocatechuic acid Catechin solution;

[0059] (2) Add 7.2g of EDC, protocatechuic acid solution, and 4.3g of NHS into a 20mL MES buffer reactor in sequence, and control the pH range to 5; then place it in an ice-water bath, and react with magnetic stirring for 0.5h;

[0060] (3) Add the fully dissolved chitosan solution into the reactor, and react for 6 hours at room temperature and normal pressure;

[0061] (4) Put the reaction solution into a dialysis bag, dialyze with tap water for 48 hours, and then dialyze with deionized water for 24 hours. After the dialysate is freeze-dried, the chitosan-protocatechuic acid graft copolymer is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com