Rectification technology capable of separating rectifying section from stripping section

A technology of the stripping section and the rectifying section, which is applied in the field of separation and purification of substances, can solve the problems of environmental impact on water quality, large latent heat of vaporization, increased energy consumption, etc., and achieve the effects of reducing secondary pollution, reducing decomposition products, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

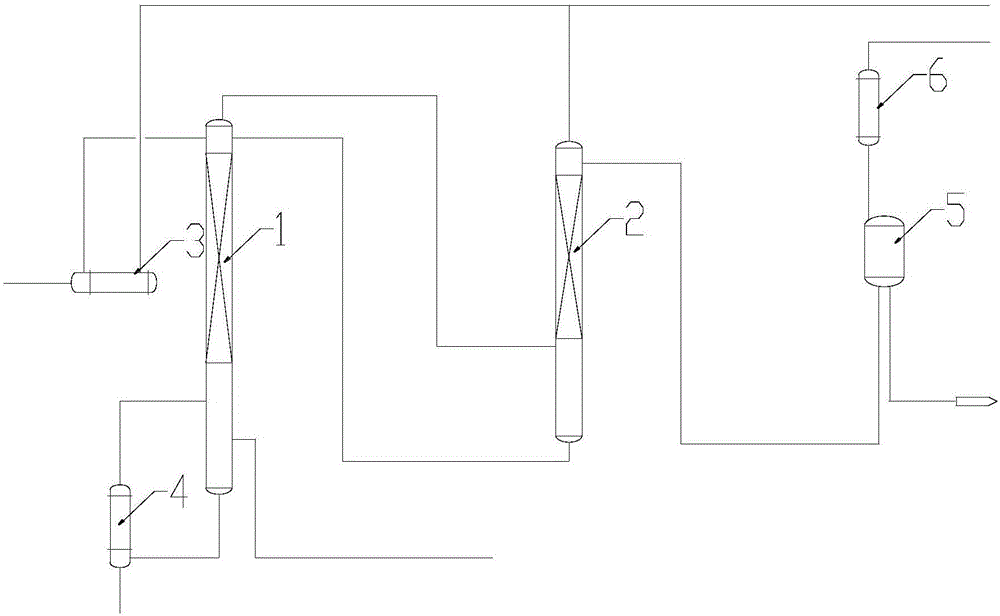

[0053] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0054] A kind of rectification process that separates rectification section and stripping section, comprises dehydration process and product refining process, and this method comprises the steps:

[0055] (1) preheating the waste liquid containing the target product, and feeding it through the upper part of the dehydration A tower 1;

[0056] (2) Heating the material in the dehydration A tower 1, the steam rising to the top of the dehydration A tower 1 enters the dehydration B tower 2; the steam at the top of the dehydration B tower 2 enters the first reflux tank 5 after being condensed into a liquid, and the first reflux tank A part of the liquid in 5 is pumped back to the dehydration B tower 2, and a part of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com