Clipping device for pipes

A cutting device and pipe material technology, which is applied in metal processing and other directions, can solve the problems of heating temperature not reaching the cutting temperature, increasing equipment cost, and difficulty in collecting waste dust and waste, so as to improve cutting efficiency, simple and practical structure, and save money input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

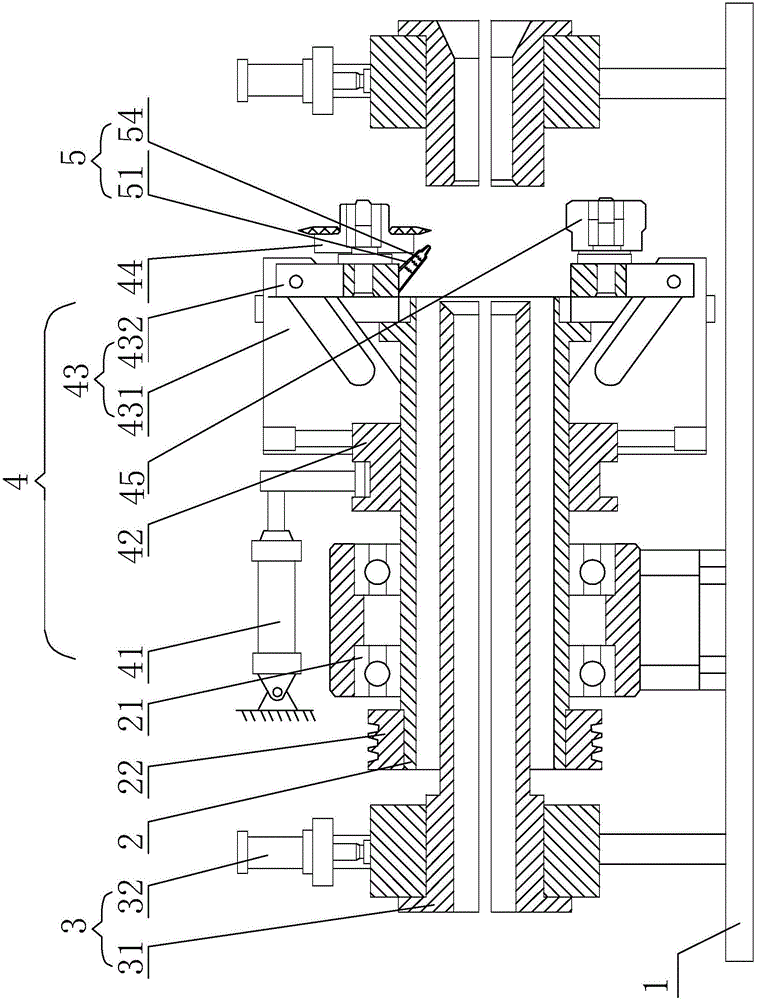

[0024] Embodiment 1, the heating device 5 includes a blower and an air supply pipe 51 , the nozzle of the air supply pipe 51 is aligned with the pipe cutout, and the air supply pipe 51 is provided with a heating wire 54 . Further, the air supply pipe 51 is fixed on the cutting device 4 , and the air supply pipe 51 is also provided with a temperature sensor for controlling the heating temperature of the heating wire 54 .

[0025] After receiving the cutting signal, the half-type clamping block 31 fixed on the machine base 1 clamps the plastic pipe under the action of the cylinder 32, and the power source drives the drum 2 to rotate at a certain speed through the V-belt pulley 22. Under the action of pushing the cylinder 41, the guide block 431 drives the cutting device 4 and the limit support roller 45 to move radially towards the pipe material at the same time. At this time, the heating device 5 starts to work, and the air blower blows the air heated by the electric heating wir...

Embodiment 2

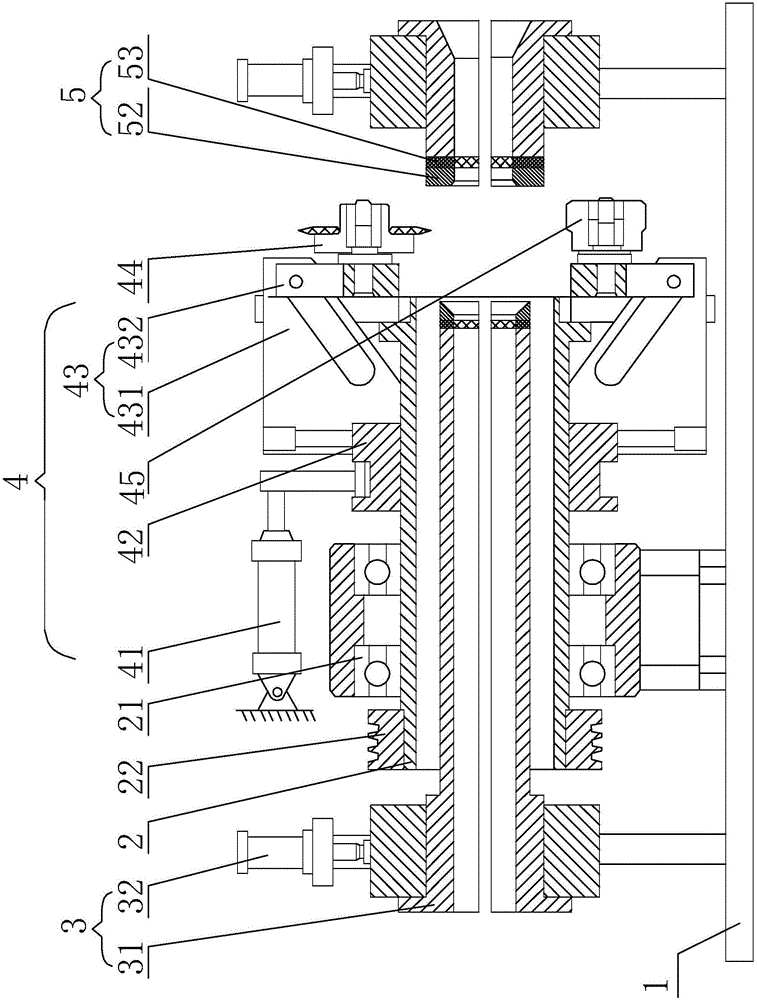

[0026] Embodiment 2, with reference to figure 2 The heating device 5 is an electric heater 52 fixed on the clamping device 3 close to the cut of the pipe. In order to achieve a good heating effect on the cut of the pipe, a partition is provided between the heating device 5 and the clamping device Thermal layer 53. When receiving the cutting signal, the heating device 5 starts to work, the electric heater 52 generates heat, and conducts the heat to the pipe clamped by the clamping device 3, and the pipe incision is heated and softened, and the cutting head 44 rotates the plastic pipe to a fixed length. cut.

[0027] Plastic pipes such as HDPE and PVC are thermoplastic polymers, which will soften when heated, and solidify and form after cooling, without changing the basic structure and performance of the material. A heating device 5 for heating and softening at the pipe cutout is provided to heat and soften the pipe After cutting, no debris and dust will be generated, the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com