Vehicle hub aftertreatment equipment

A technology for automotive wheel hubs and post-processing, which is applied to metal processing equipment, grinding/polishing equipment, and parts of grinding machine tools, etc. It can solve problems such as inconvenient steering and inability to remove wheel hub burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

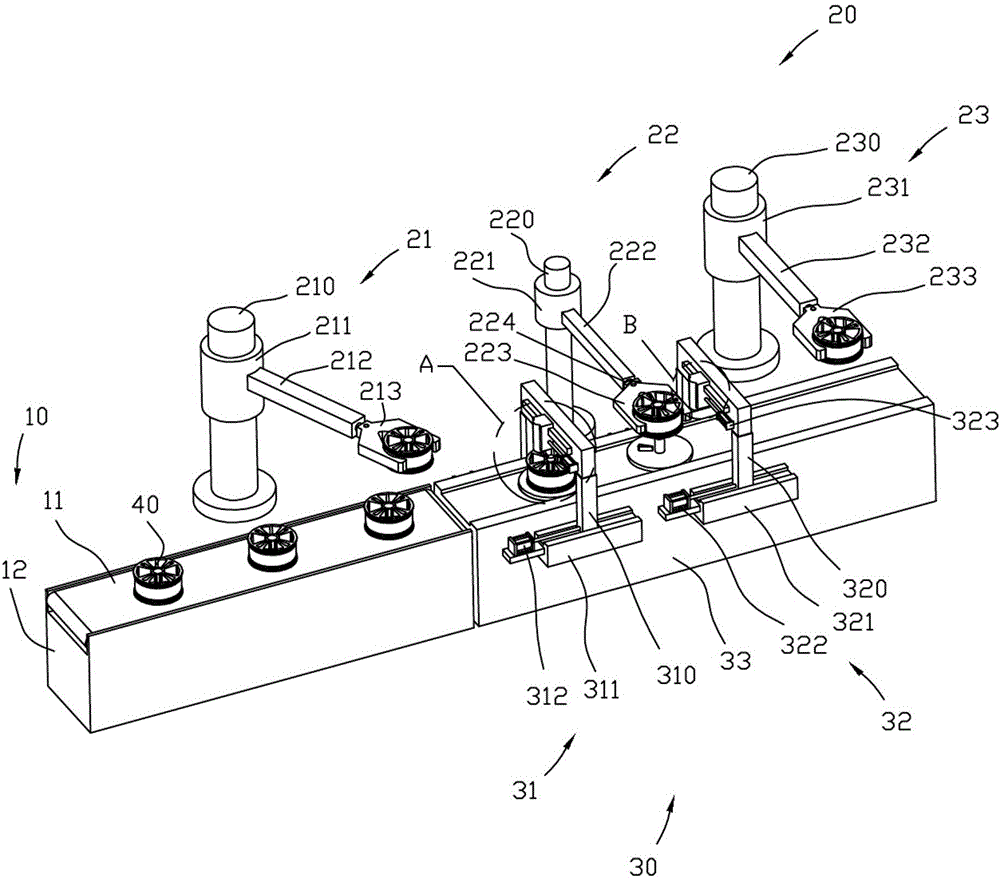

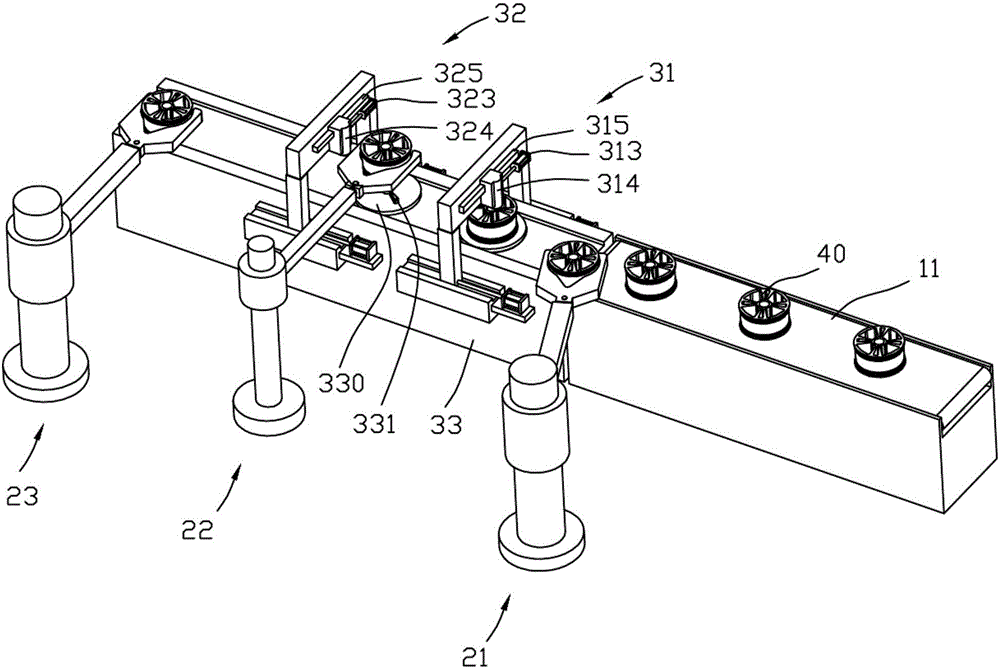

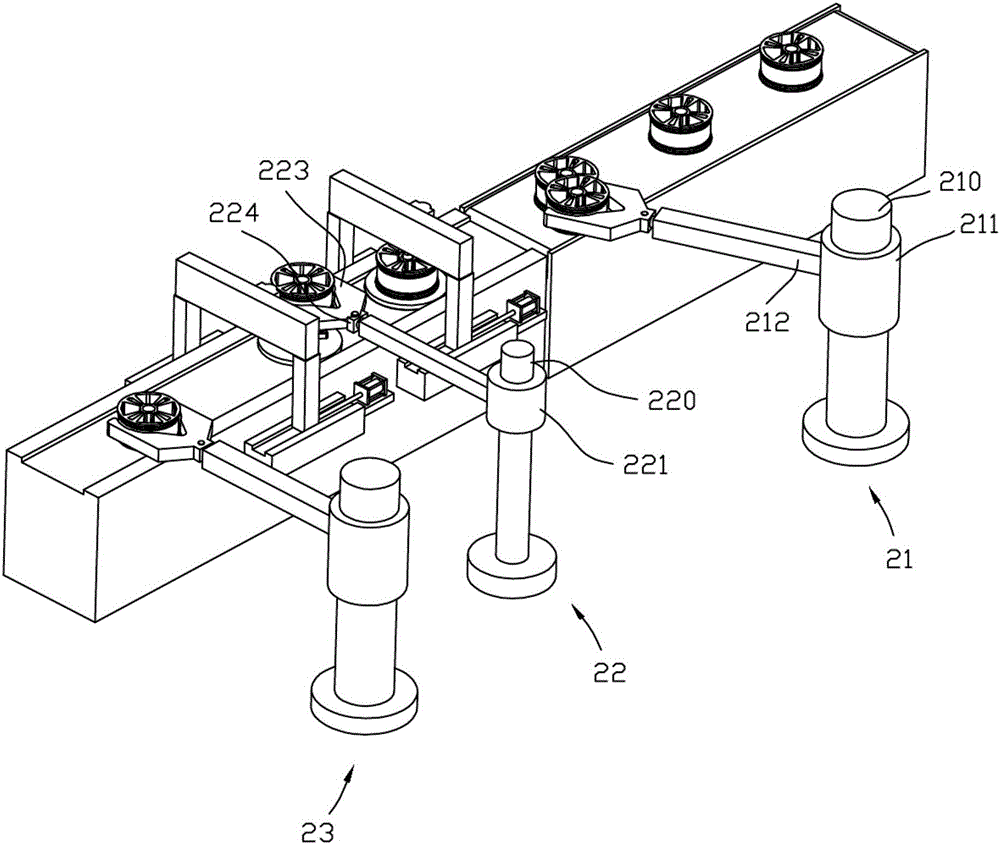

[0019] Such as Figure 1 to Figure 3 As shown, a post-processing equipment for automobile wheels includes a conveying assembly 10, a manipulator assembly 20, and a grinding assembly 30. The conveying assembly 10 includes a conveyor belt 11 and a conveyor base 12, and the conveyor belt 11 is located on the conveyor base 12. above; the manipulator assembly 20 includes a first manipulator 21, a second manipulator 22 and a third manipulator 23, and the first manipulator 21, the second manipulator 22 and the third manipulator 23 respectively include a first gripper 213, a second The gripper 223 and the third gripper 233, the first gripper 213, the second gripper 223 and the third gripper 233 are respectively connected with the first operating arm 212, the second operating arm 222 and the third operating arm 232, wherein the first A turning module 224 is also provided between the two grippers 223 and the second operating arm 222; the grinding assembly 30 includes a grinding platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com