Metal powder flux-cored wire for 1000 MPa high-strength steel and production process thereof

A technology of flux-cored welding wire and production process, applied in the field of metal powder type flux-cored welding wire for 1000MPa high-strength steel and its production process, can solve the problems of few varieties of high-strength steel flux-cored welding wire, high fatigue strength, high formability, etc. Improve welding efficiency, reduce slag amount, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

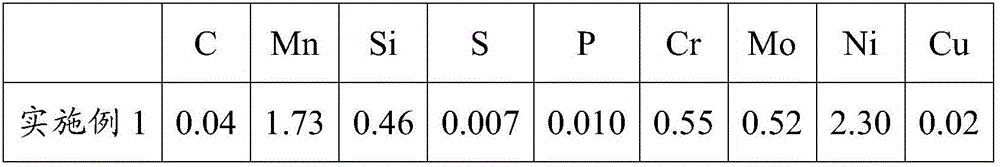

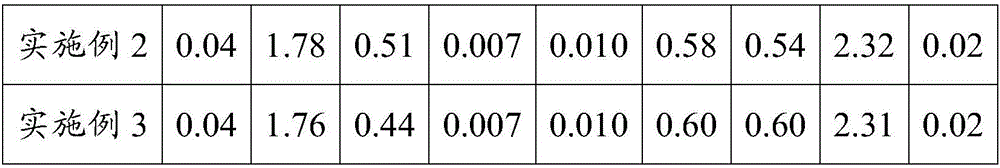

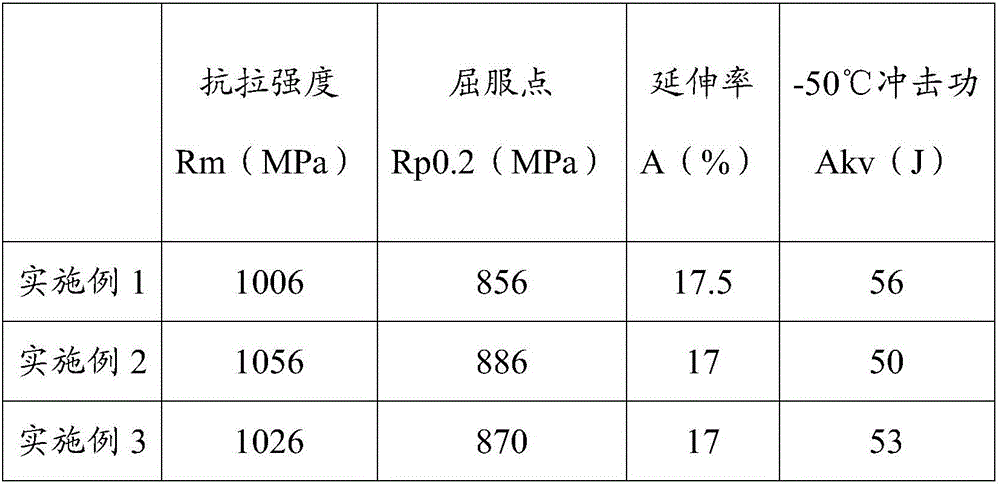

Embodiment 1

[0039] A low-carbon steel strip of (width×thickness) 14mm×0.8mm is used as the steel sheath of the flux-cored wire, and its chemical composition is: C 0.029wt%, Mn 0.24wt%, Si 0.013wt%, S 0.004wt%, P 0.009wt% and the balance Fe and unavoidable impurities.

[0040] Taking the preparation and production of 100Kg flux-cored wire as an example, the powder core in this embodiment accounts for 14.5wt% of the total mass of the entire flux-cored wire, that is, the weight of the powder core is 14.5Kg; wherein, the components in the powder core are: manganese-silicon alloy 0.73kg, ferrosilicon powder 0.58kg, ferrosilicon powder 0.15kg, sodium fluoride 0.029kg, manganese powder 1.74kg, nickel powder 2.03kg, molybdenum iron 1.06kg, chromium powder 0.54kg, and the iron powder of surplus; The components of the medicinal powder core are sieved and mixed uniformly before use.

[0041] Put the low-carbon steel strip in the welding wire forming machine, inject the ready-to-use powder core into...

Embodiment 2

[0043] The steel sheath of the flux-cored wire is the same as in Example 1.

[0044] Taking the preparation and production of 100Kg welding wire as an example, the powder core of this embodiment accounts for 15.5wt% of the total mass of the entire flux-cored wire, that is, the weight of the powder core is 15.5kg; wherein, each component in the powder core is: manganese-silicon alloy 0.78kg, silicon 0.62kg of iron powder, 0.16kg of titanium iron powder, 0.03kg of sodium fluorosilicate, 1.86kg of manganese powder, 2.17kg of nickel powder, 1.09kg of ferromolybdenum, 0.57kg of chromium powder, and the remaining iron powder; All components are sieved and mixed evenly before use.

[0045] Put the low-carbon steel strip in the welding wire forming machine, inject the ready-to-use powder core into the groove of the steel strip bent transversely into a "U" shape, and then roll it into wire and reduce the diameter to Φ1. 6mm to get 1000MPa high-strength steel metal powder cored wire. ...

Embodiment 3

[0047] The steel sheath of the flux-cored wire is the same as in Example 1.

[0048] Taking the preparation and production of 100Kg welding wire as an example, the powder core of this embodiment accounts for 14.5wt% of the total mass of the entire flux-cored wire, that is, the weight of the powder core is 14.5Kg; wherein, the components in the powder core are: manganese-silicon alloy 1.02kg, silicon Iron powder 0.44kg, titanium iron powder 0.15kg, potassium fluoroaluminate 0.03kg, manganese powder 1.60kg, nickel powder 2.03kg, molybdenum iron 1.16kg, chromium powder 0.58kg, and iron powder of the balance; All components are sieved and mixed evenly before use.

[0049] Put the low-carbon steel strip in the welding wire forming machine, inject the ready-to-use powder core into the groove of the steel strip bent transversely into a "U" shape, and then roll it into wire and reduce the diameter to Φ1. 2mm to get 1000MPa high-strength steel metal powder cored wire.

[0050] The fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com