Novel ship monitoring magnetic field sensor

A magnetic field sensor and sensor technology, applied in the size/direction of the magnetic field, the use of electromagnetic devices for magnetic field measurement, instruments, etc., can solve the problems of difficult manufacturing of superconducting Josephson junctions, large influence of magnetic field gradients, and complex system structure, etc. Achieve the effect of superior recognition ability, high concealment and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

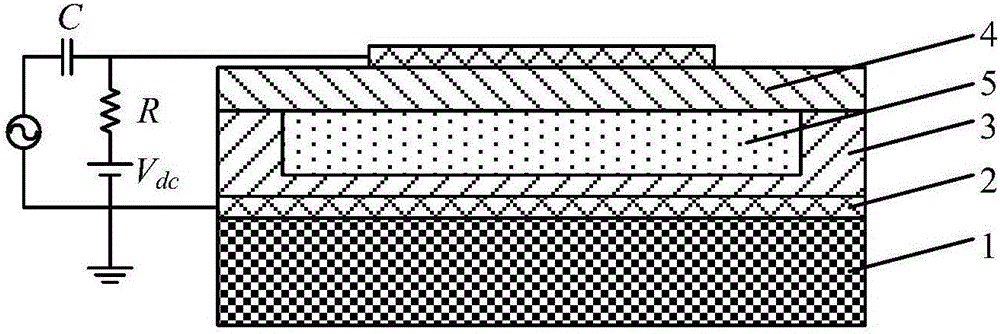

[0037] The present invention provides a new type of naval ship monitoring magnetic field sensor, which comprises a silicon substrate 1, a metal electrode 2, an insulating layer 3, a piezoelectric film 4 and a capacitor cavity 5 filled with magnetic liquid. The specific implementation method of the present invention will be described below in conjunction with the drawings and embodiments.

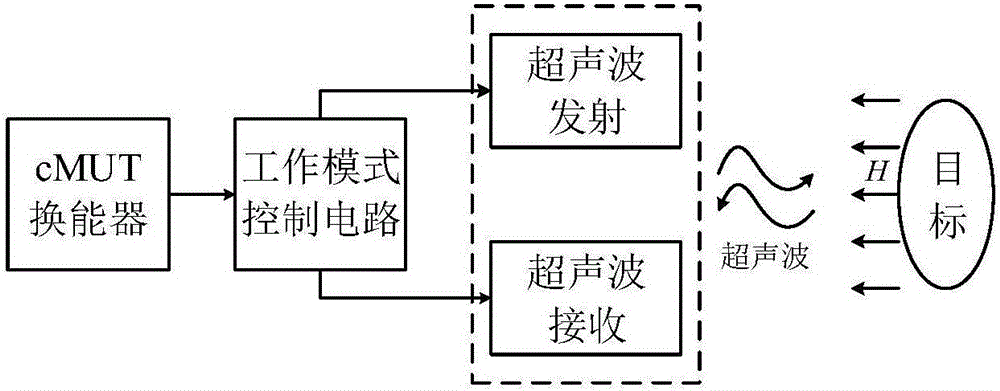

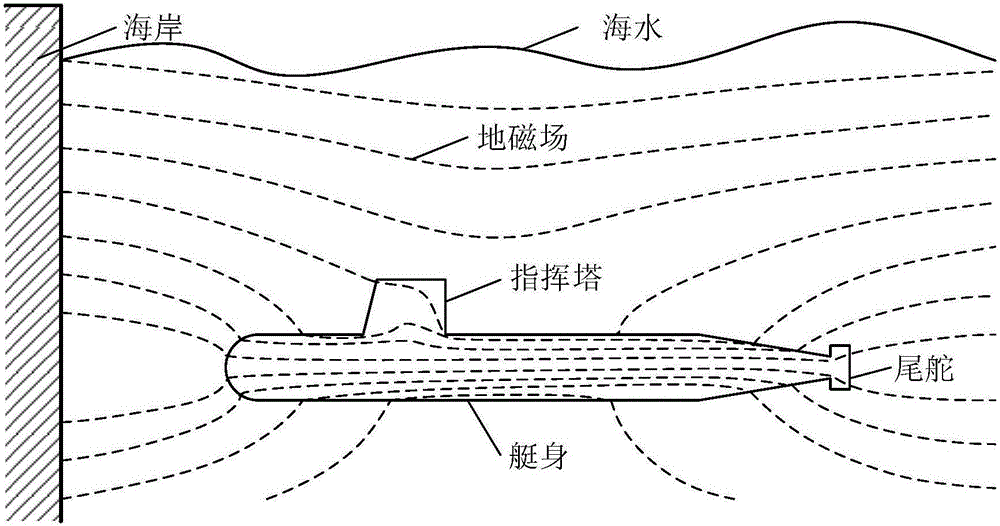

[0038] This embodiment provides a new type of ship monitoring magnetic field sensor, and its specific technical implementation ideas: use MEMS technology to design and manufacture a capacitive micro-machined ultrasonic transducer (cMUT) as an underwater acoustic transducer, in which the pair is injected into the capacitive cavity The magnetic field-sensitive low-concentration magnetic liquid is used as the ultrasonic transmission medium. In the absence of a magnetic anomaly source, the sensor works as an underwater acoustic transducer. When the submarine approaches the coast, it will cause magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com