An optical fiber sensing system and method for on-line monitoring of hydrogen and impurity content in petrochemical hydrogen-carrying pipelines

An optical fiber sensing system and technology of impurity content, which are applied in the field of online monitoring system for hydrogen concentration and impurity content, and can solve the problems of increasing content, unavoidable, and decreasing content of effective component H, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

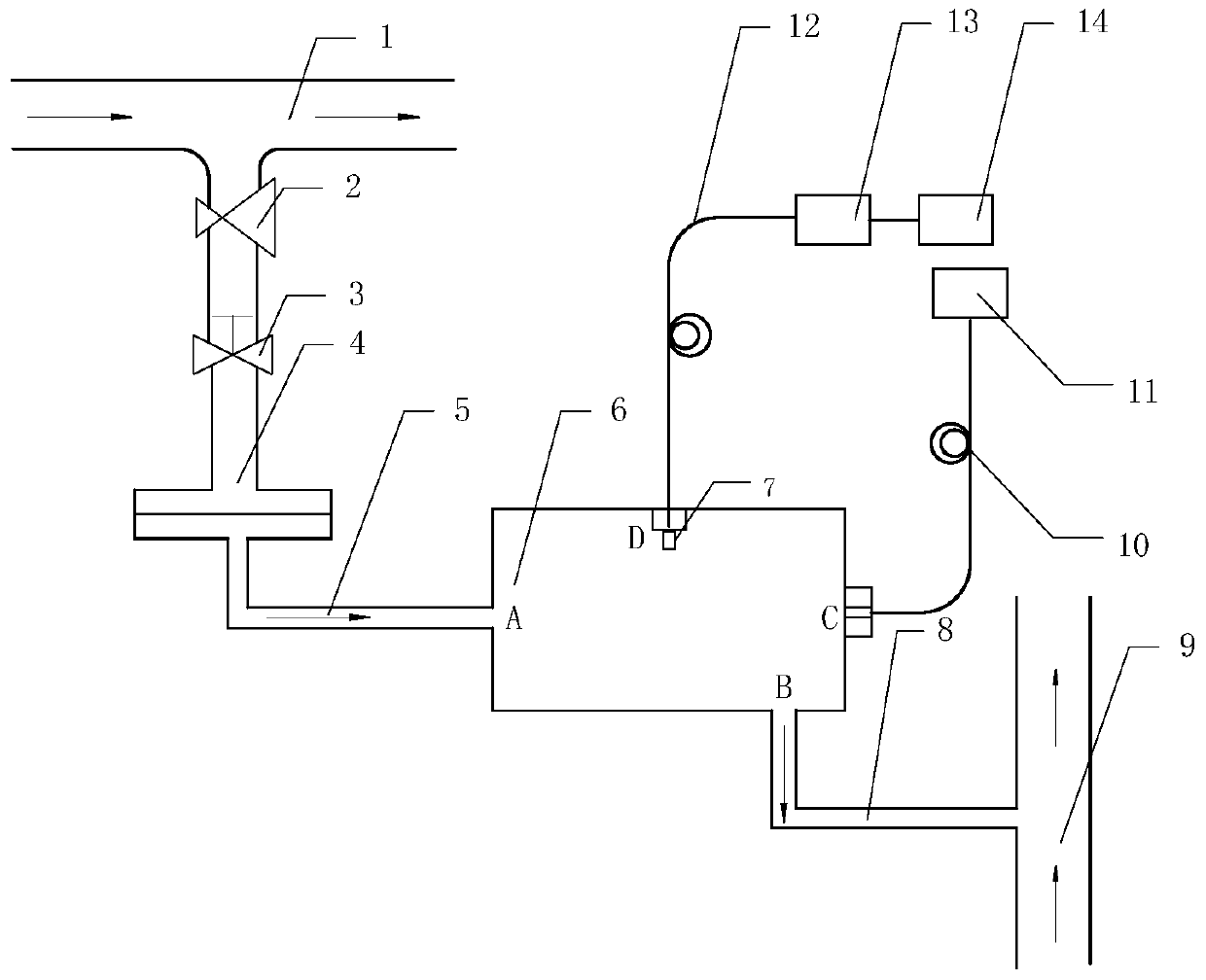

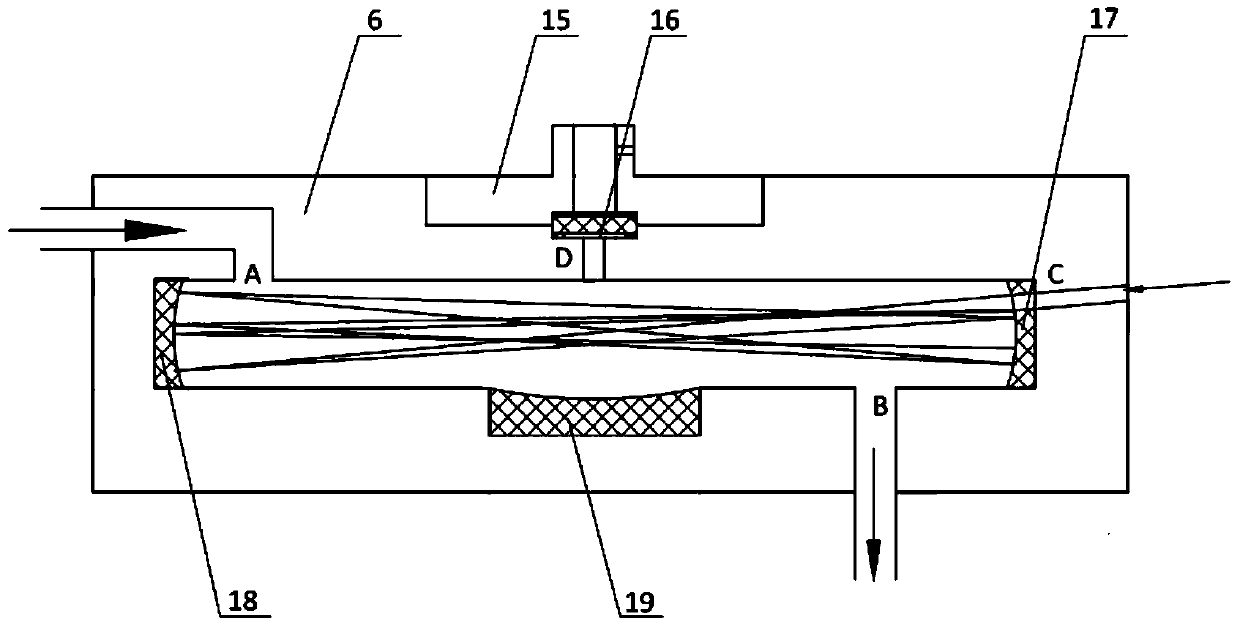

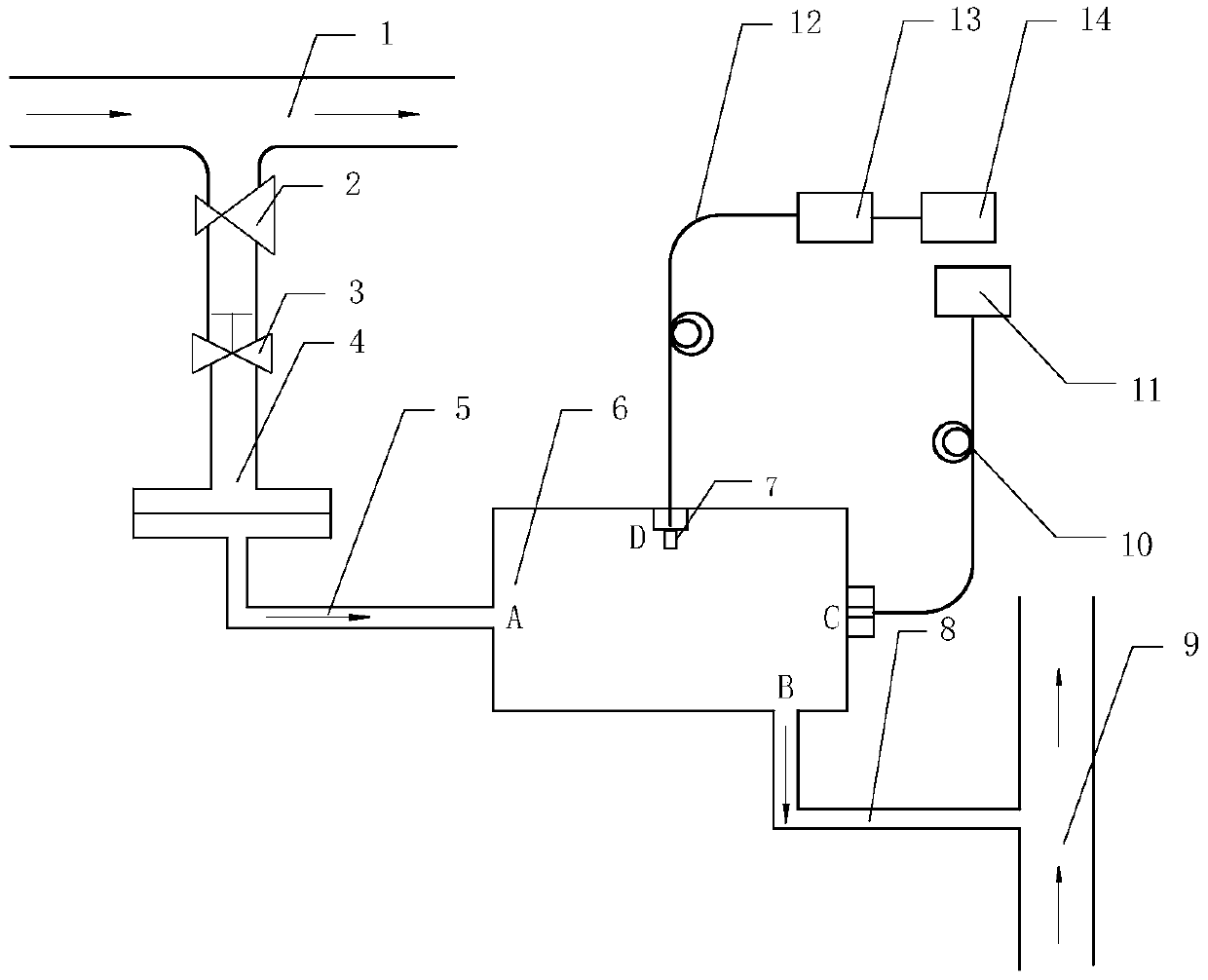

[0023] Such as figure 1 As shown, the optical fiber sensing system and method for on-line monitoring of hydrogen and impurity content in petrochemical hydrogen-carrying pipelines of the present invention include measuring gas guide bypass pipe (4), optical signal enhancing gas chamber (6), light source unit (11), signal A detection unit (7), a signal demodulation unit (13), a data processing unit (14) and the like.

[0024] When the system is running, firstly adjust the pressure reducing valve (2) to reduce the pressure entering the optical signal enhancement chamber (6) to ensure the safety of the measurement system, then open the shut-off valve (3), and the petrochemical hydrogen-carrying main pipeline The gas in (1) enters the optical signal enhancement gas chamber (6) through the measuring gas guide bypass pipe (4) and the air inlet pipe (5) successively, and enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com