A layout structure combining traffic tunnel and belt conveyor

A technology of belt conveyor and layout structure, applied in tunnels, underground transportation, tunnel lining and other directions, can solve the problems of high cost of measures, poor economy, unfavorable safe operation of belt conveyors, etc., to achieve economical rationality, ensure safe operation, and avoid excessively high effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

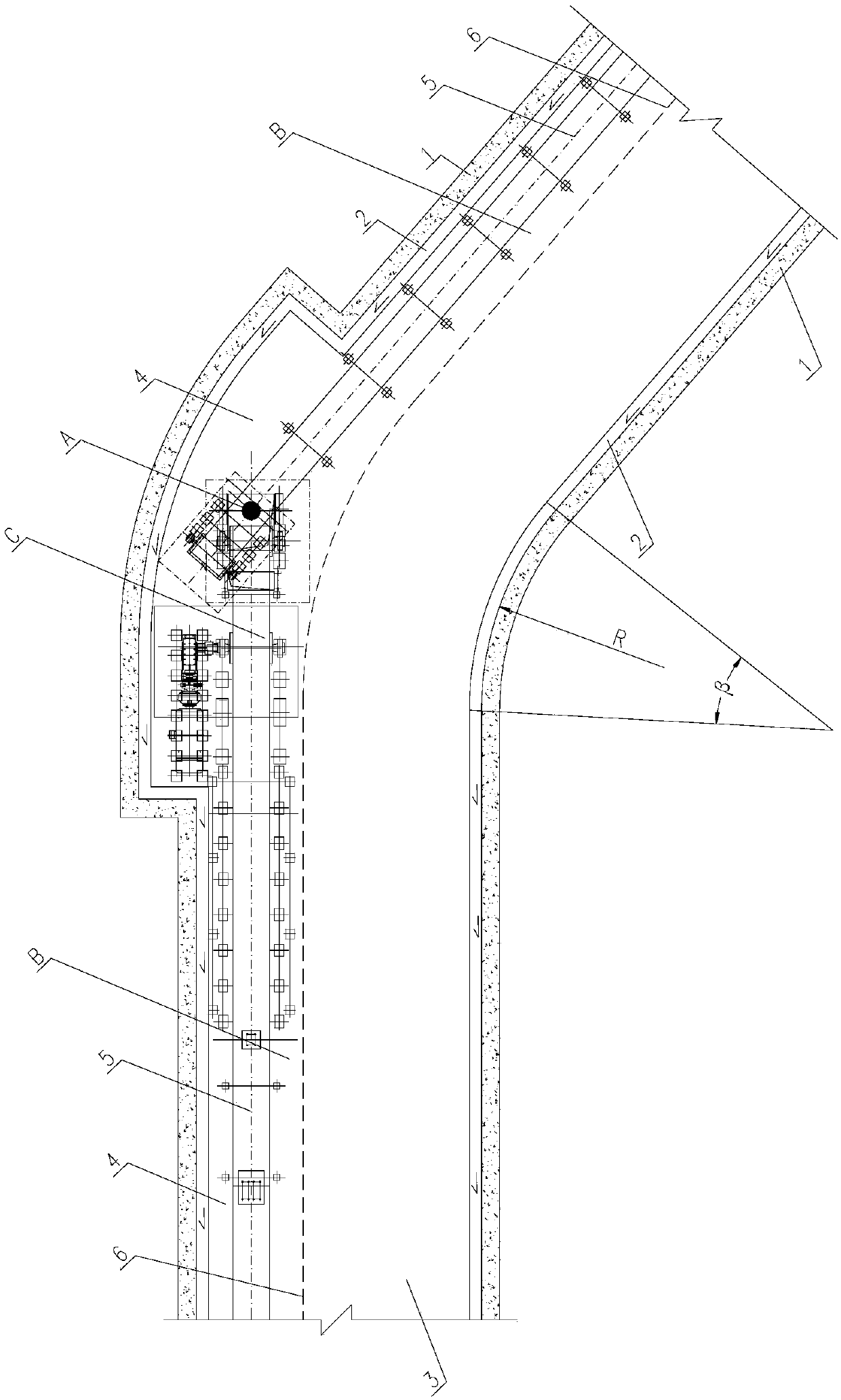

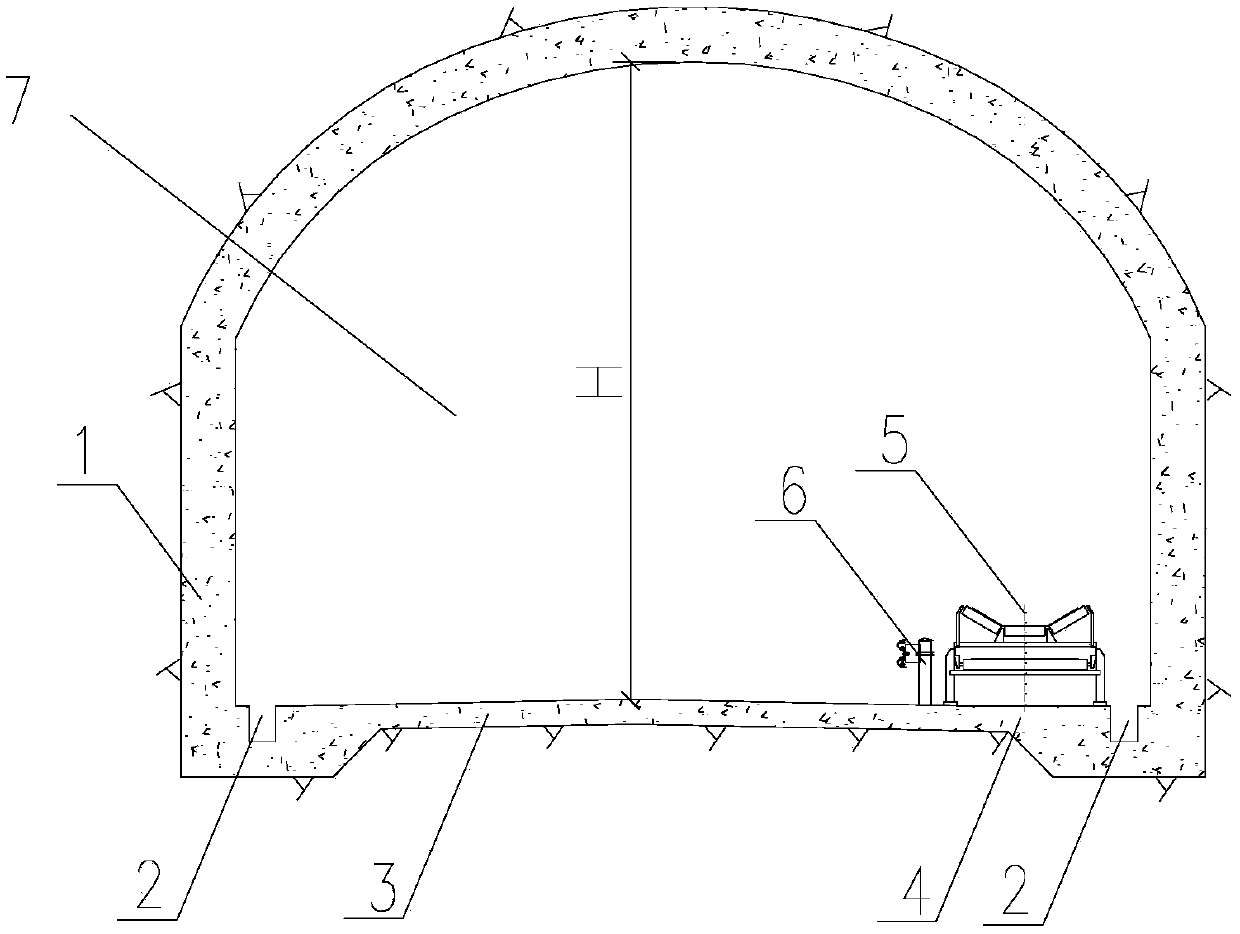

[0016] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and at the same time, the advantages of the present invention will become clearer and easier to understand.

[0017] refer to Figure 1-3 Shown: the arrangement structure of a kind of traffic tunnel of the present invention and belt conveyor combination is characterized in that: in tunnel 7, one side is provided with belt conveyor conveyor road 4, and the other side is driveway 3, and in described belt conveyor A belt conveyor 5 is installed on the conveying path 4, a protective fence 6 is set between the conveying path 4 of the conveyor belt conveyor and the driving lane 3, and a tunnel lining 1 is arranged on the top arch and side walls of the tunnel 7. A gutter 2 is provided at the junction of the tunnel lining 1 and the floor.

[0018] The cross-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com