Small colloid mill for manufacturing asphalt road surface and use method thereof

A kind of technology of asphalt pavement and colloid mill, which is applied in the field of crushing, grinding or crushing, which can solve the problems of easy tearing of the pavement, high maintenance cost, poor wear resistance of the pavement, etc., achieve thorough cross-linking reaction, reduce maintenance cost, and resist road surface peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

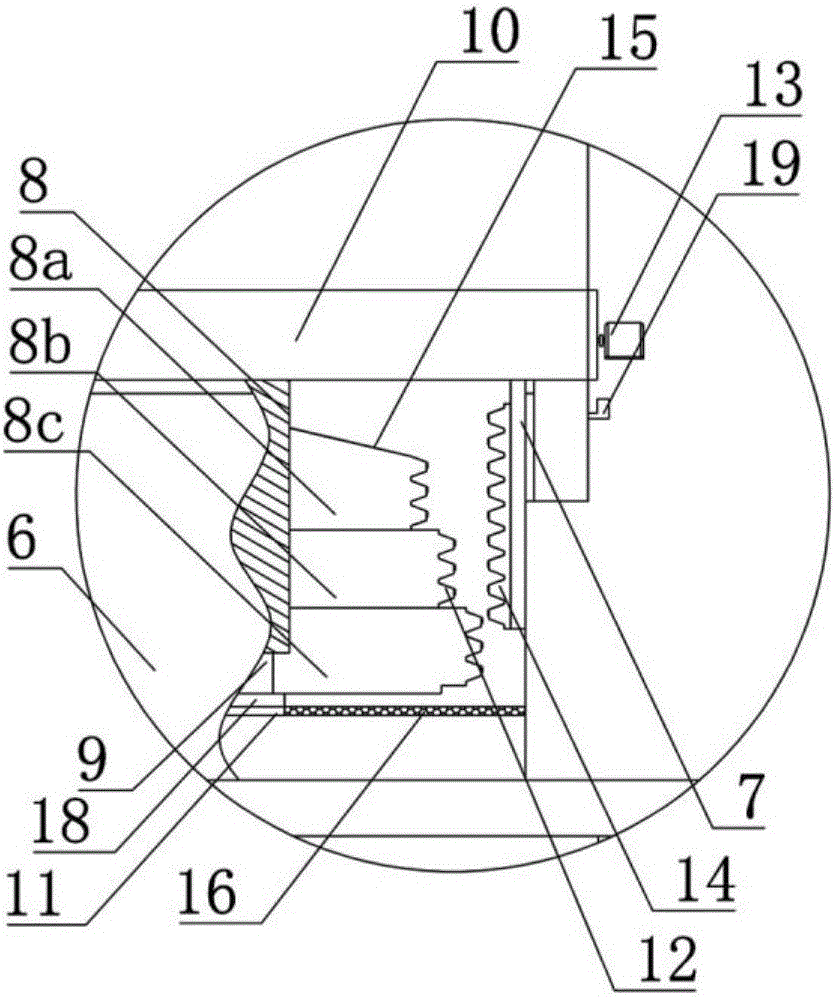

[0053] Such as figure 1 , figure 2 As shown, the small colloid mill used to manufacture asphalt pavement includes a motor housing 1, a vertical motor, a grinding disc structure 2, a hopper 3, a self-circulation pipe 4 and a cooling water pipe joint 5, and the motor housing 1 is provided with a vertical motor. There is a grinding plate structure 2 above the motor housing 1, and a feeding hopper 3 is arranged above the grinding plate structure 2. The upper side wall of the grinding plate structure 2 is connected to the cooling water pipe joint 5, and the lower side wall of the grinding plate structure 2 is connected to the lower end of the self-circulation pipe 4, and the upper end of the self-circulation pipe 4 Extending to the feeding hopper 3, the millstone structure 2 includes a millstone shell 6, a millstone stator 7, a millstone rotor 8, a first rotating shaft 9, an adjustment ring 10 for controlling the movement of the millstone stator 7 up and down, and the first rotati...

Embodiment 2

[0061] Such as figure 1 , figure 2 As shown, the small colloid mill used to manufacture asphalt pavement includes a motor housing 1, a vertical motor, a grinding disc structure 2, a hopper 3, a self-circulation pipe 4 and a cooling water pipe joint 5, and the motor housing 1 is provided with a vertical motor. There is a grinding plate structure 2 above the motor housing 1, and a feeding hopper 3 is arranged above the grinding plate structure 2. The upper side wall of the grinding plate structure 2 is connected to the cooling water pipe joint 5, and the lower side wall of the grinding plate structure 2 is connected to the lower end of the self-circulation pipe 4, and the upper end of the self-circulation pipe 4 Extending to the feeding hopper 3, the millstone structure 2 includes a millstone shell 6, a millstone stator 7, a millstone rotor 8, a first rotating shaft 9, an adjustment ring 10 for controlling the movement of the millstone stator 7 up and down, and the first rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com