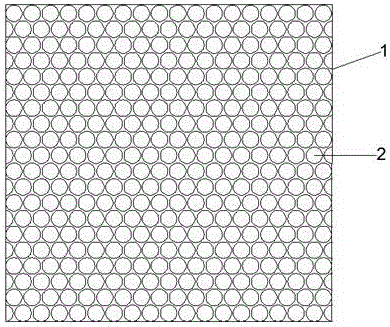

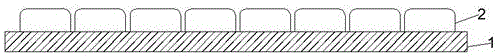

Novel flexible anti-cutting and stab-resistant discrete composite material and preparation method for same

A technology of composite material and softness, which is applied in the field of new soft cut-resistant stab-proof discrete composite material and its preparation, can solve the problems of poor flexibility and comfort, low protective function, etc., to reduce shear force and cut damage, The effect of good air permeability and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

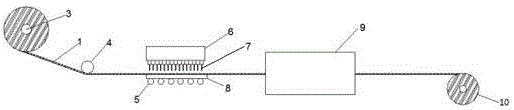

Method used

Image

Examples

Embodiment 1

[0060] Nylon plain weave fabric is used as the base fabric, the surface density is 180g / m2, and the warp and weft density is 308*316 / (root / 10cm); by weight, the polymer glue component ratio is: E51 epoxy resin 100 50 parts, 50 parts of 650 polyamide curing agent, 4 parts of dioctyl phthalate toughening agent, 2 parts of epoxy resin thinner (SM-90), 4 parts of color particles, butylated toluene (BHT) antioxidant 0.5 servings.

[0061] The preparation process of the discrete flexible anti-cut anti-needle discrete composite material of the present embodiment is as follows:

[0062] (1) Preparation of polymer glue: Weigh the raw materials of the above-mentioned polymer glue composition ratio, heat and mix E51 epoxy resin and 650 polyamide curing agent, then add dioctyl phthalate toughener, epoxy Resin thinner (SM-90), color particles and butylated toluene (BHT) antioxidant, mechanically stirred until uniformly mixed, left to defoam for 30 minutes, and completely defoamed to obtai...

Embodiment 2

[0067] Using polyester plain weave fabric as the base fabric, the surface density is 210g / m2, and the warp and weft density is 160*166 / (root / 10cm); by weight, the proportion of the polymer glue component is: E44 epoxy resin 100 Parts, 80 parts of 650 polyamide curing agent, heat and mix, then add 10 parts of dioctyl phthalate toughening agent, 7 parts of epoxy resin thinner (SM-90), 5 parts of color particles, butylated toluene (BHT) 1.5 parts of antioxidant, 1 part of stilbene derivative fluorescent agent; and choose zirconium corundum as the rigid particle material with a particle size of 100 μm.

[0068] The preparation process of the discrete flexible anti-cut anti-needle discrete composite material of the present embodiment is as follows:

[0069] (1) Preparation of polymer glue: Weigh the raw materials of the above-mentioned polymer glue composition ratio, heat and mix E44 epoxy resin and 650 polyamide curing agent, then add dioctyl phthalate toughener, ring Oxygen resi...

Embodiment 3

[0074] Aramid plain weave fabric is used as the base fabric, the surface density is 207g / m2, and the warp and weft density is 93*95 / (root / 10cm); by weight parts, the distribution ratio of the polymer glue is: polycarbonate 100 9 parts of dioctyl phthalate toughening agent, 7 parts of epoxy resin diluent (SM-90), 4 parts of color particles, 0.7 parts of butylated toluene (BHT) antioxidant .

[0075] The preparation process of the discrete flexible anti-cutting anti-needle composite material of the present embodiment is as follows:

[0076] (1) Preparation of polymer glue: Weigh the raw materials of the above-mentioned polymer glue composition ratio, heat and melt polycarbonate at 180°C, and then add dioctyl phthalate toughener and epoxy resin diluent ( SM-90), colored particles, butylated toluene (BHT) antioxidant, mechanically stirred until uniformly mixed, left to defoam for 30 minutes, and completely defoamed to obtain polymer glue;

[0077] (2) Dispensing molding: Pour th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com