Printing and dyeing equipment with dust removal and drying device

A printing and dyeing equipment and drying device technology, which is applied in the field of printing and dyeing equipment with dust removal and drying devices, can solve problems such as difficult storage, affect fabric quality, and change printing and dyeing effects, and achieve the effect of saving time and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

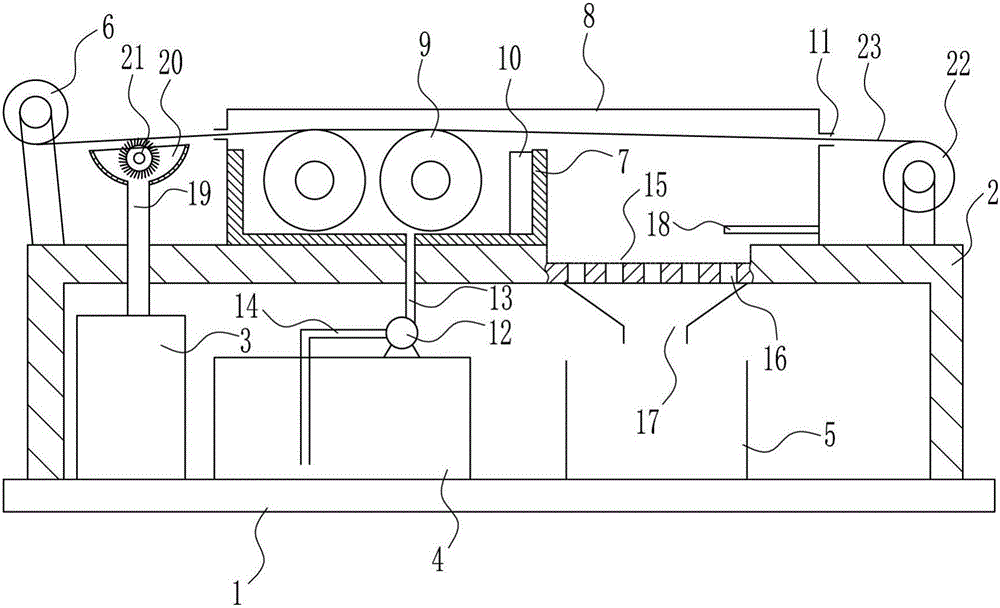

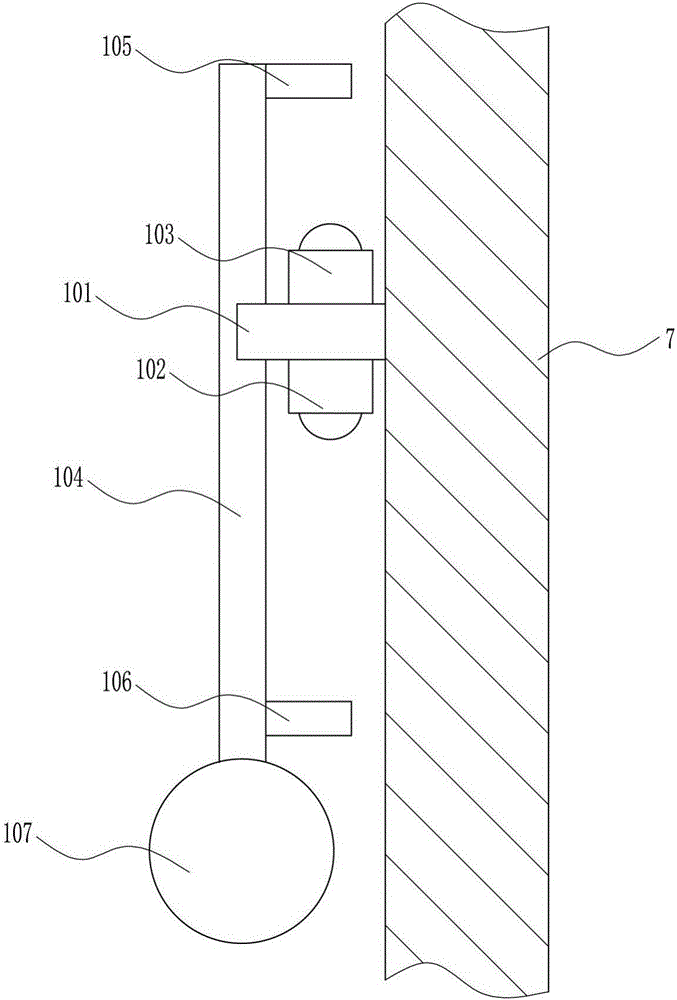

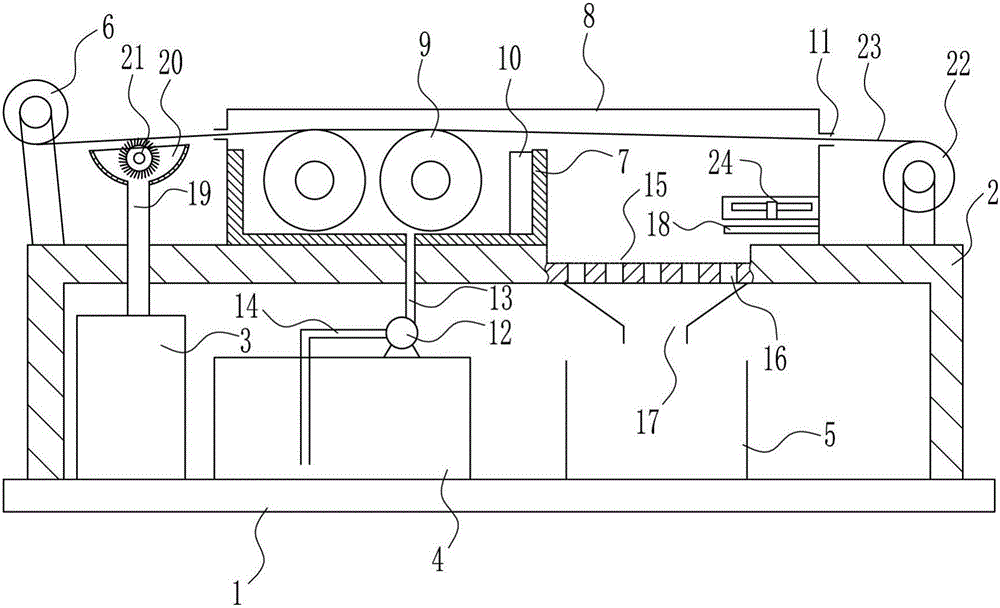

[0034] A kind of printing and dyeing equipment with dedusting and drying device, such as Figure 1-6 As shown, it includes bottom plate 1, N-type bracket 2, vacuum cleaner 3, printing and dyeing liquid tank 4, collection box 5, unwinding roller 6, printing and dyeing box 7, dust cover 8, electric printing and dyeing roller 9, liquid level detection device 10. Liquid suction pump 12, first liquid inlet pipe 13, second liquid inlet pipe 14, collecting bucket 17, first heating plate 18, dust suction pipe 19, dust suction hood 20, electric roller brush 21 and electric winding roller 22. An N-shaped support 2 is provided on the bottom plate 1. The bottom plate 1 inside the N-shaped support 2 is provided with a vacuum cleaner 3, a printing and dyeing liquid tank 4 and a collection box 5 in sequence from left to right. Roller wheel 6 and printing and dyeing box 7, unwinding roller wheel 6 is positioned at the left side of printing and dyeing box 7, and the top right side of N-type su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com