Clean gold extraction device and method

The technology of an extraction device and an extraction method is applied in the field of clean gold extraction devices, which can solve the problems of low leaching efficiency of refractory ore, high toxicity, and pollution of the environment by the gold extraction process, and achieves increased solubility, increased mass transfer efficiency, and improved leaching. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

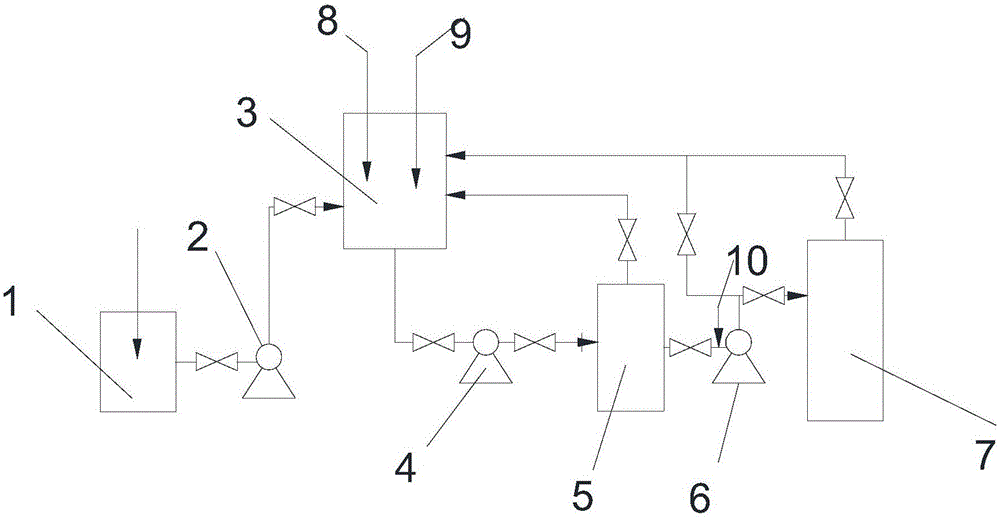

[0064] The present invention provides a clean gold extraction device, please refer to figure 1 , is a schematic structural diagram of the device, including a dosing system, a reaction tank 3, a solid-liquid separation system, a micro-nano bubble generating device 6, and a gold adsorption system 7.

[0065] Specifically, the reaction tank 3 is provided with a pH meter 8 and a feed port 9, the feed port 9 is used to add mineral powder to the reaction tank 3, and the pH meter 8 is used to measure the mixed liquid in the reaction tank 3. pH value.

[0066] Specifically, the dosing system is connected to the reaction tank 3 for adding gold extractant to the reaction tank 3 .

[0067] As an example, the dosing system includes a dosing tank 1 and a dosing pump 2 ; the dosing pump 2 is connected between the dosing tank 1 and the reaction tank 3 . Valves are provided before and after the dosing pump 2, and after the gold extractant is prepared in the medicine tank 1, the front and re...

Embodiment 2

[0086] The present invention also provides a gold extraction method. The gold extraction method adopts the clean gold extraction device described in any one of Embodiment 1.

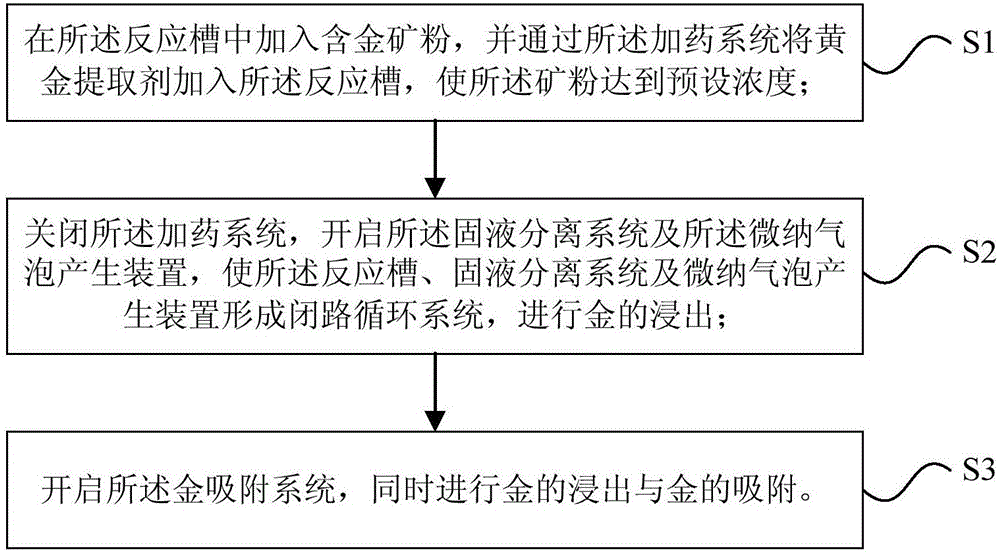

[0087] see figure 2 , shown as a process flow chart of the gold extraction method, comprising the steps:

[0088] First execute step S1: add gold-containing ore powder into the reaction tank, and add gold extractant to the reaction tank through the dosing system, so that the ore powder reaches a preset concentration.

[0089] Specifically, the gold-containing ore powder can be any gold-containing ore powder, which can be obtained by pulverizing gold-containing ore. The average particle size of the mineral powder is preferably 0.1-500 μm. The gold extractant can adopt any existing gold extractant. In this embodiment, the gold extractant is preferably a cyanide-free extractant to reduce environmental pollution.

[0090] As an example, the cyanide-free extractant contains amino acid with a mass fraction ...

Embodiment 3

[0105] Sulfur-containing gold ore, its main components are 65% of quartz, 8% of kaolinite, 20% of pyrophyllite, and 8% of pyrite. After powdering, the particle size is less than 74 μm. Configure a cyanide-free extractant in the dosing tank, the concentration of glycine is 0.75%, the pH is adjusted to 11-12 with sodium hydroxide, it is injected into the reaction tank through the dosing pump, the concentration of mineral powder is controlled at 5%, and the dosing pump is turned off. Turn on the ceramic membrane separation system and the gas-liquid mixing pump to ensure a liquid-gas ratio of 10:1 and maintain a pressure of 0.3MPa. After 8 hours of reaction, open the front and rear valves of the modified PAN membrane adsorption system, and start to absorb while leaching. After 24 hours, the leaching rate of the obtained mineral powder is greater than 90%. Gold adsorbed by PAN membrane can be desorbed with glycine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com