Semi-aromatic polyamide based on furan dicarboxylic acid and preparation method thereof

A technology of semi-aromatic polyamide and furandicarboxylic acid, which is applied in the field of semi-aromatic polyamide and its preparation based on furandicarboxylic acid, and can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

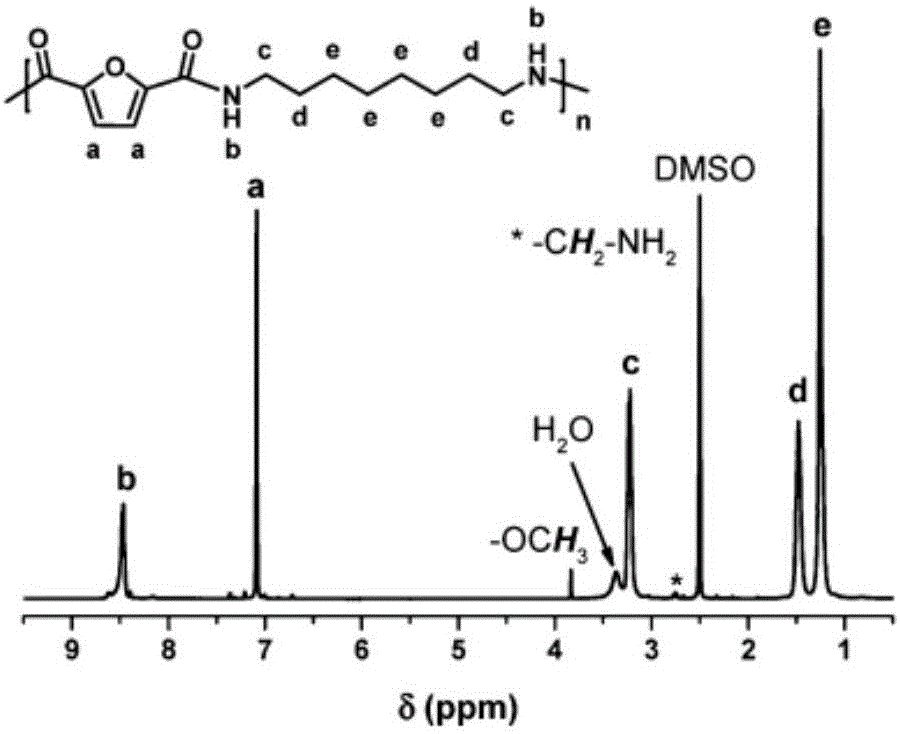

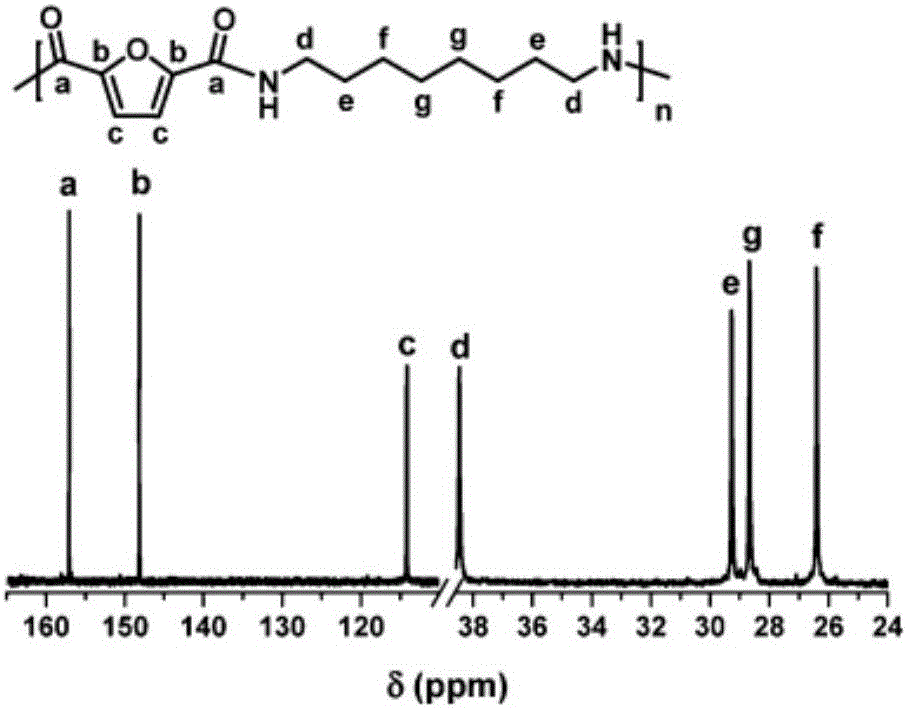

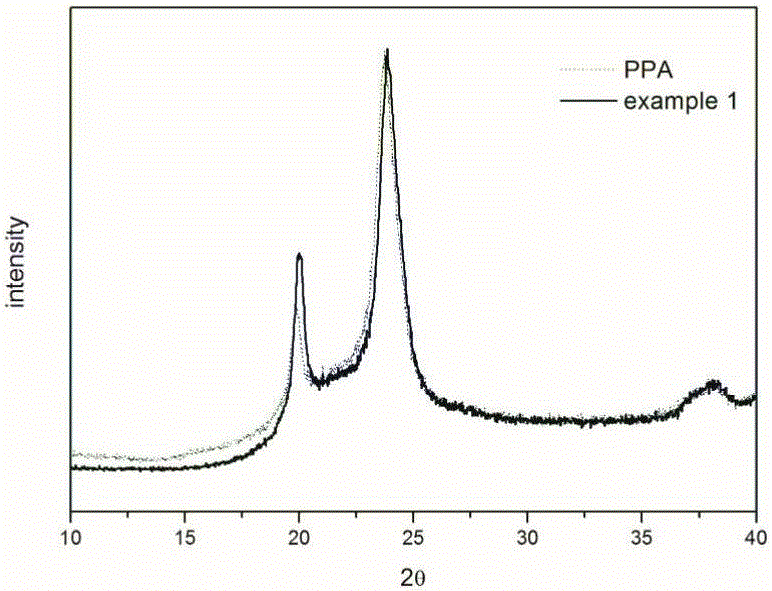

Embodiment 1

[0029] The Candida sp.99-125 lipase (0.18g, 20wt%) and pre-activated molecular sieve (1.78g, 200wt%) were added to a nitrogen-protected round bottom flask. Then dimethyl furandicarboxylate (0.5000g, 2.715mmol), 1,8-octanediamine (0.3917g, 2.715mmol) and anhydrous toluene (4.46g, 500wt%) were added to the flask, and the flask was sealed. Stir mechanically at 60°C for 72 hr. Then spin the solvent toluene to dryness, dissolve the product with formic acid, filter out the enzyme and molecular sieve, concentrate the toluene solution, add the concentrated solution dropwise to the excess 1,4-dioxane, and separate the crude product by decantation and centrifugation , And then dissolve the crude product in formic acid, then add the formic acid solution dropwise to excess methanol (-20℃), and then centrifuge to obtain a solid, then vacuum drying, the yield reached 65%, the molecular weight reached 46000g / mol, melting point It is 147°C and the glass transition temperature is 116°C. Prepa...

Embodiment 2

[0031] The Candida sp.99-125 lipase (0.08g, 10wt%) and the pre-activated molecular sieve (1.55g, 200wt%) were added to a nitrogen-protected round bottom flask. Then dimethyl furandicarboxylate (0.5000g, 2.715mmol) and 1,5-pentanediamine (0.2772g, 2.715mmol) and anhydrous diphenyl ether (3.89g, 500wt%) were added to the flask, and the flask Seal and stir mechanically at 80°C for 72hr. Then the solvent diphenyl ether was spin-dried, the product was dissolved with formic acid, the enzyme and molecular sieve were filtered, the formic acid solution was concentrated, and the concentrated solution was added dropwise to the excess 1,4-dioxane. The crude product was combined by decantation After centrifugation, the crude product was dissolved in formic acid, and the formic acid solution was added dropwise to excess methanol (-20°C), and then the solid was centrifuged to obtain a solid, which was then vacuum dried. The yield reaches 63%, the molecular weight reaches 40,000 g / mol, the me...

Embodiment 3

[0033] The Candida sp.99-125 lipase (0.12g, 15wt%) and pre-activated molecular sieve (1.6g, 200wt%) were added to a nitrogen-protected round bottom flask. Then dimethyl furandicarboxylate (0.5000g, 2.715mmol), 1,6-hexamethylenediamine (0.3153g, 2.715mmol) and anhydrous benzene (4.08g, 500wt%) were added to the flask, and the flask was sealed. Stir mechanically at 70°C for 60 hr. Then spin-dry the solvent benzene, dissolve the product with formic acid, filter out the enzyme and molecular sieve, concentrate the formic acid solution, add the concentrated solution dropwise to the excess 1,4-dioxane, and separate the crude product by decantation and centrifugation , And then dissolve the crude product in formic acid, add the formic acid solution dropwise to excess methanol (-20°C), and then centrifuge to obtain a solid, and then vacuum dry. The yield reached 60%, the molecular weight reached 43000 g / mol, the melting point was 149°C, and the glass transition temperature was 119°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com