Adhesive composition and adhesive film

A bonding film and composition technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve the problems of insufficient adhesion between the adherend and the adhesive layer, and achieve excellent Effect of reworkability and high adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Nitrogen gas was introduced into a reaction apparatus equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen introduction pipe, thereby replacing the air in the reaction apparatus with nitrogen. Then, 100 parts by weight of butyl acrylate, 0.2 parts by weight of 8-hydroxyoctyl acrylate and 60 parts by weight of solvent (ethyl acetate) were added into the reaction device. Then, 0.1 parts by weight of azobisisobutyronitrile as a polymerization initiator was dropped over 2 hours, and reacted at 65° C. for 6 hours to obtain a compound used in Example 1 with a weight average molecular weight of 1 million or more. Acrylic Polymer Solution 1. A part of the acrylic polymer was taken and used as a sample for acid value measurement described later.

Embodiment 2~5 and comparative example 1~3

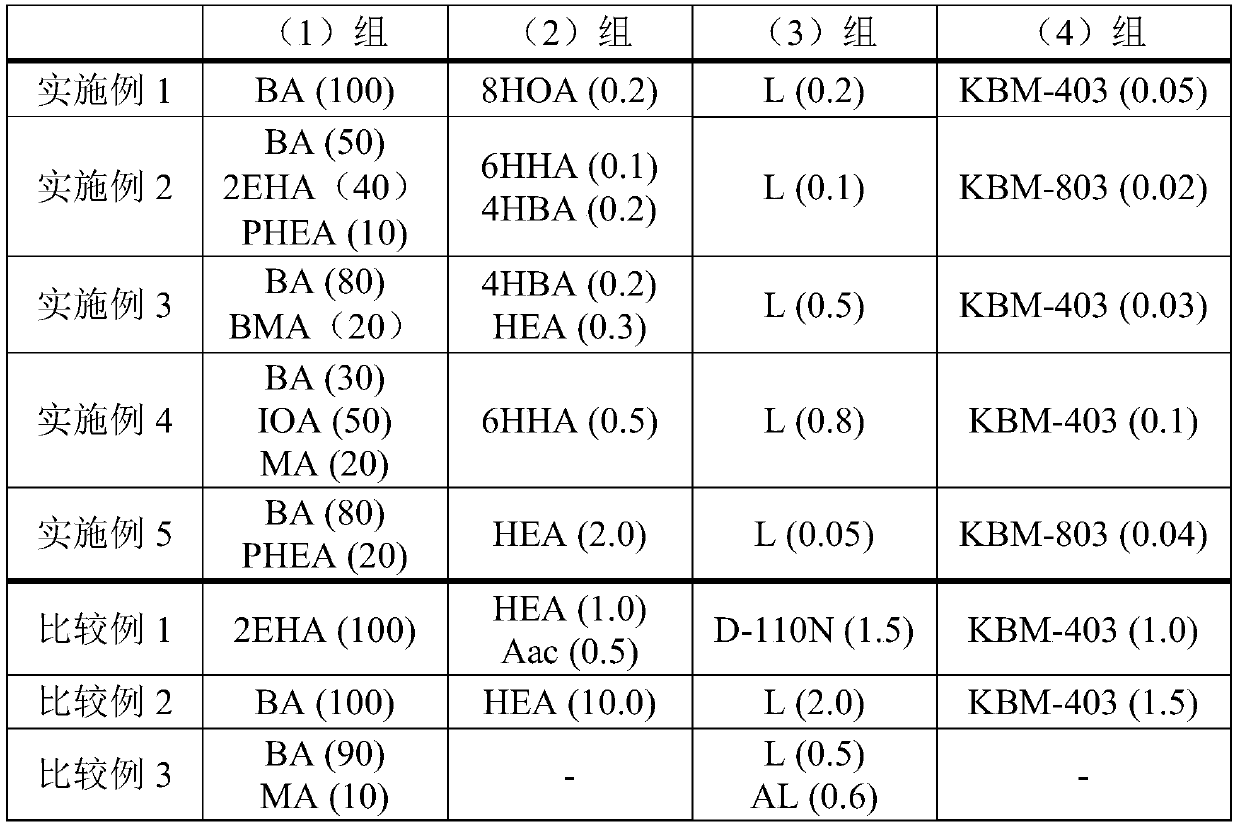

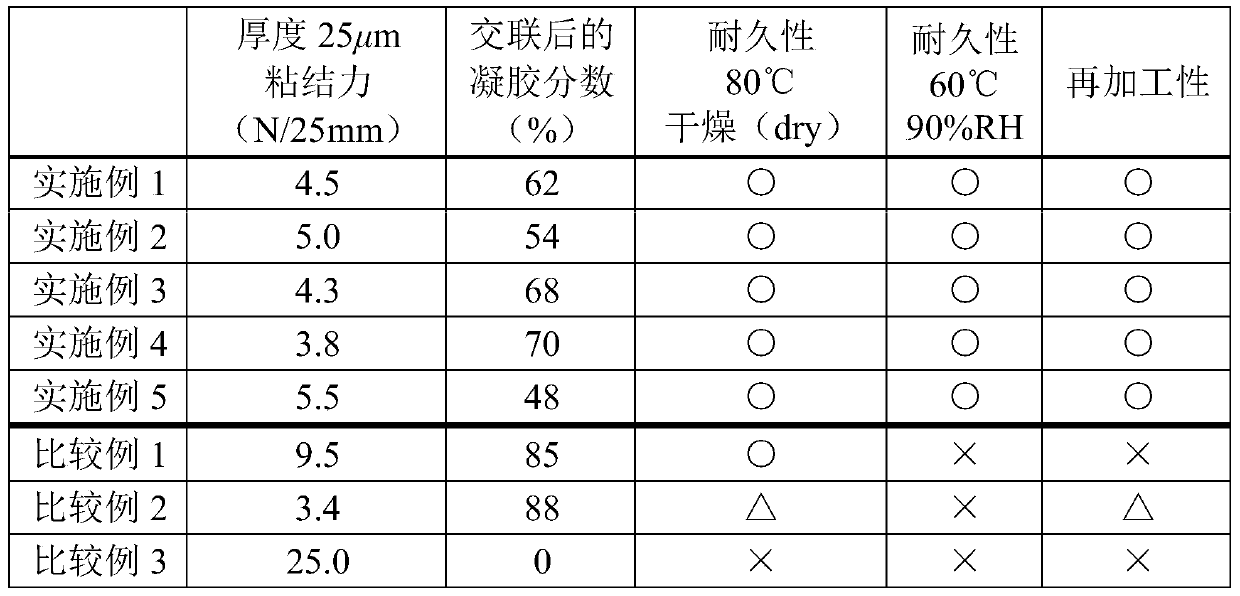

[0101] Except that the composition of each monomer was adjusted as described in the groups (1) and (2) in Table 1, the above-mentioned acrylic polymer solution 1 used in Example 1 was operated in the same manner to obtain the Acrylic polymer solutions in Examples 2-5 and Comparative Examples 1-3. In addition, although the measurement result is not shown in particular, the weight average molecular weight of the acrylic polymer contained in the acrylic polymer solution of Examples 2-5 and Comparative Examples 1-3 was 1 million or more.

[0102]

[0103] [Example 1]

[0104] To the acrylic polymer solution 1 of Example 1 produced as described above, 0.2 parts by weight of Coronate L (Coronate L) (trimethylolpropane (TMP) adduct of toluene diisocyanate (TDI) compound) was added , 0.05 parts by weight of KBM-403 (3-glycidoxypropyltrimethoxysilane) and stirred and mixed to obtain the adhesive composition of Example 1. This adhesive composition is coated on a release film made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com