High performance low temperature sintered hexagonal M-type strontium ferrite and preparation method thereof

A low-temperature sintering and strontium ferrite technology, which is applied in the field of high-performance low-temperature sintering hexagonal M-type strontium ferrite and its preparation, can solve the problems of sintering density, saturation magnetization, poor coercive force and electromagnetic properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

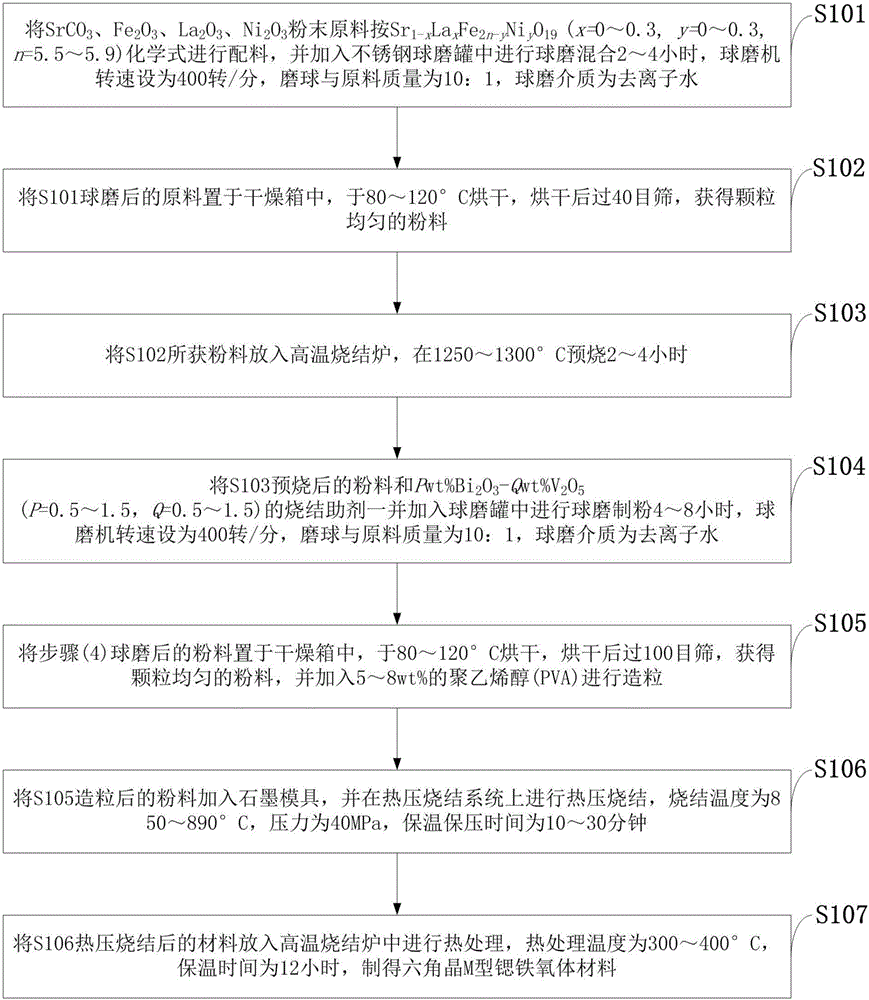

[0066] Such as figure 1 As shown, the preparation method of the high-performance low-temperature sintered hexagonal M-type strontium ferrite in the embodiment of the present invention includes the following steps:

[0067] S101: SrCO 3 , Fe 2 o 3 , La 2 o 3 、Ni 2 o 3 Powder raw material according to Sr 1-x La x Fe 2n-y Ni y o 19 (x=0~0.3, y=0~0.3, n=5.5~5.9) chemical formula for batching, and put it into a stainless steel ball mill tank for ball milling and mixing for 2 to 4 hours. The speed of the ball mill is set to 400 rpm. The quality is 10:1, and the ball milling medium is deionized water;

[0068] S102: Put the ball-milled raw material of S101 in a drying oven, dry it at 80-120°C, pass it through a 40-mesh sieve after drying, and obtain a powder with uniform particles;

[0069] S103: putting the powder obtained in S102 into a high-temperature sintering furnace, and pre-sintering at 1250-1300° C. for 2-4 hours;

[0070] S104: the powder and Pwt% Bi after pr...

Embodiment 1

[0079] 1. According to Sr 0.9 La 0.1 Fe 11.7 Ni 0.1 o 19 Components are batched, and the SrCO with a purity greater than 99.9wt% is weighed 3 -12.28g, Fe 2 o 3 -86.32g, La 2 o 3 -0.64g, Ni 2 o 3 -0.76g, a total of 100g of powder; put 100g of powder and 1000g of balls into a stainless steel ball mill tank, add an appropriate amount of deionized water, and mill on a planetary ball mill for 4 hours, with the speed of the ball mill set at 400 rpm;

[0080] 2. Put the ball-milled raw material in a drying oven, dry it at 120°C and pass it through a 40-mesh sieve to obtain a powder with uniform particles; pre-fire the powder at 1250°C for 2 hours;

[0081] 3. Weigh 80g of the pre-fired powder and put it into the ball mill jar, and weigh 1wt% Bi 2 o 3 -0.8g and 1wt% of V 2 o 5 -0.8g was added to the ball mill jar, and then 800g of balls were weighed and added to the mill jar, an appropriate amount of deionized water was added, and ball milled on a planetary ball mill for...

Embodiment 2

[0087] 1. According to Sr 0.8 La 0.2 Fe 11.7 Ni 0.1 o 19 Components are batched, and the SrCO with a purity greater than 99.9wt% is weighed 3 -11.0g, Fe 2 o 3 -86.94g, La 2 o 3 -1.29g, Ni 2 o 3 -0.77g, a total of 100g of powder; add 100g of powder and 1000g of magic balls into a stainless steel ball mill tank, add an appropriate amount of deionized water, and mill on a planetary ball mill for 4 hours, with the speed of the ball mill set at 400 rpm;

[0088] 2. Put the ball-milled raw material in a drying oven, dry it at 120°C and pass it through a 40-mesh sieve to obtain a powder with uniform particles; pre-fire the powder at 1250°C for 2 hours;

[0089] 3. Weigh 80g of the pre-fired powder and put it into the ball mill jar, and weigh 1wt% Bi 2 o 3 -0.8g and 1wt% of V 2 o 5 -0.8g was added to the ball mill jar, and then 800g of balls were weighed and added to the mill jar, an appropriate amount of deionized water was added, and ball milled on a planetary ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com