Semi-rigid asphalt pavement material and preparation method thereof

An asphalt pavement and semi-rigid technology, which is applied in the field of semi-rigid asphalt pavement materials and its preparation, can solve the problem that semi-rigid asphalt pavement resists low temperature cracking, the ability to resist base reflection cracks and fatigue cracking is reduced, the internal grouting is not compact, and the road surface is affected. Durability and other issues, to achieve the effect of reducing temperature shrinkage and drying shrinkage, comprehensive road performance, and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

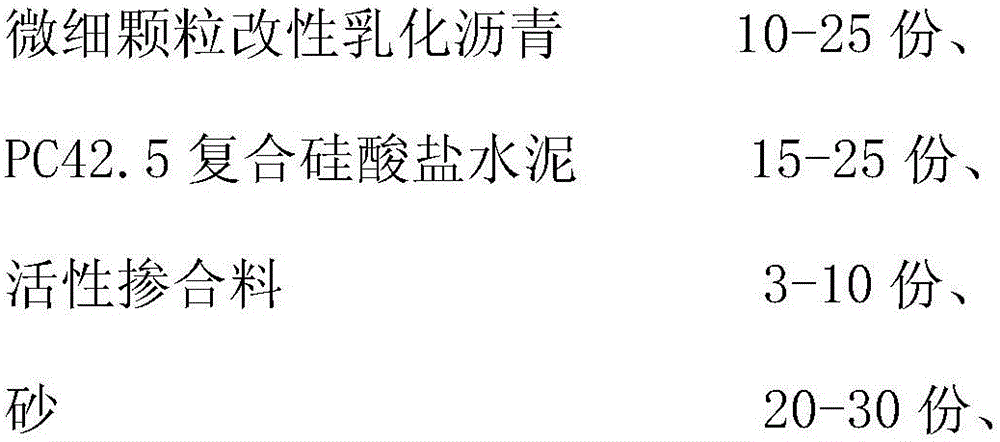

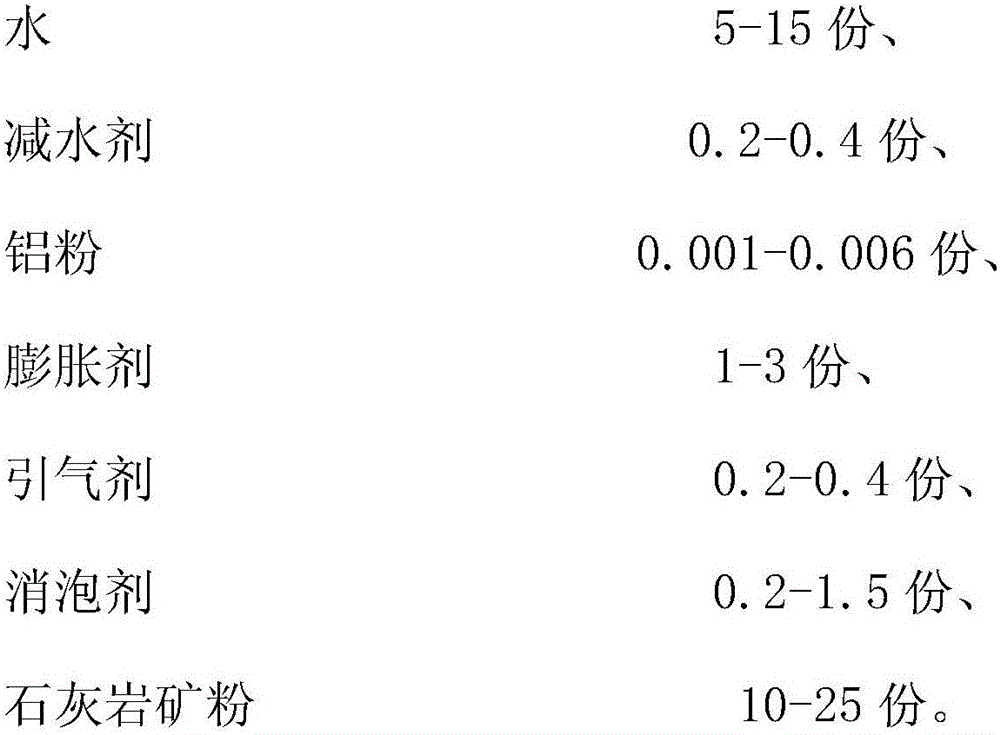

Method used

Image

Examples

Embodiment 1

[0063] The preparation method of the macroporous asphalt mixture in the embodiment of the present invention sequentially includes the following steps:

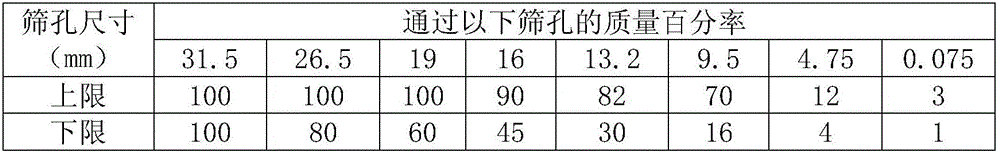

[0064] 1) Preparation of macroporous asphalt mixture: Step A, weigh 85% of the total mass by weight percentage of heavy cross 70# asphalt heated to 180°C; Step B, add 10% of the total mass of waste tire rubber powder to the Put the product obtained in step A and stir in the reaction tank; C, add 5% of the total mass of the modified stabilizer to the product obtained in step B, stir, and raise the temperature of the reaction tank to 220°C within 1 h; step D, After continuously stirring the product obtained in step C for 3 hours, the temperature is lowered to 170°C to obtain the finished rubber high-viscosity modified asphalt. Its performance indicators are shown in Table 5. In step E, the mineral material and filler are heated to 190°C, stirred and mixed for 15 seconds. The synthetic gradation is shown in Table 6; In step F, 2.5% ...

Embodiment 2

[0093] The difference between this embodiment and Embodiment 1 is:

[0094] A macroporous asphalt mixture used for semi-rigid asphalt pavement is composed of rubber high-viscosity modified asphalt, mineral aggregates, and fillers. The percentage of each component in the total mass of the macroporous asphalt mixture is: rubber high-viscosity modified asphalt 4.2%, 93% of mineral material, 2.8% of filler, total mass is 100%, the synthetic gradation of mineral material and filler mixture is shown in Table 11. Among them, the rubber high-viscosity modified asphalt is composed of Zhongjiao 70# asphalt, waste tire rubber powder, and modified stabilizer. The percentage of each component in the total mass of the rubber high-viscosity modified asphalt is: Zhongjiao 70# asphalt 78%, waste tires Rubber powder 20%, modified stabilizer 2%, its performance indicators are shown in Table 12. The performance indexes of macroporous asphalt mixture are shown in Table 13.

[0095] Table 11

[0096] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com