Method for preparing lead ion adsorbing agent

An adsorbent and lead ion technology, applied in the field of preparing lead ion adsorbents, to achieve the effects of expanding the industrial chain, fast reproduction and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

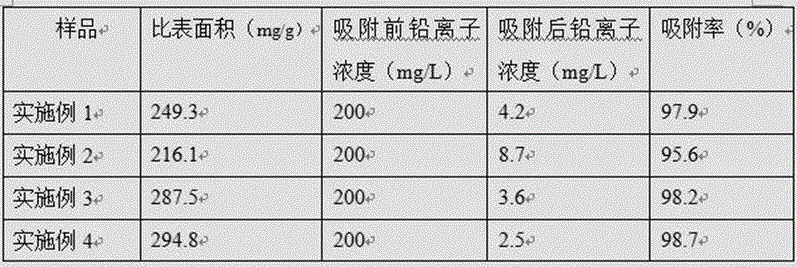

Examples

Embodiment 1

[0030] A method for preparing lead ion adsorbent, the specific operation steps are as follows:

[0031] (1) Crush 100kg of bagasse to 40 mesh, add 5mol / L sodium hydroxide solution to soak for 5 hours, then wash the bagasse with water until neutral to obtain bagasse cellulose; add 10kg of acrylic acid horseradish to the bagasse cellulose To the anhydride copolymer, add 100kg of water, mix evenly, and dry at 60°C for 3 hours to obtain modified bagasse;

[0032] (2) Take 50 kg of sargassum powder and 8 kg of thiourea and add them to an ultrasonic mixer, then add 80 kg of water and conduct an ultrasonic reaction for 30 minutes at an ultrasonic frequency of 40 kHz, place the reacted paste in an oven at 80° C. for heating and drying for 2 hours to obtain Modified sage algae powder;

[0033] (3) Add the above-mentioned modified bagasse and modified sargassum powder to the agitator, add 4 kg of cerium sulfate solution and 12 kg of starch, then add water and adjust it into a paste, pu...

Embodiment 2

[0035] A method for preparing lead ion adsorbent, the specific operation steps are as follows:

[0036] (1) Crush 100kg of bagasse to 40 mesh, add 3mol / L sodium hydroxide solution to soak for 6h, then wash the bagasse with water until neutral to obtain bagasse cellulose; To the anhydride copolymer, add 120kg of water, mix evenly, and dry at 80°C for 2 hours to obtain modified bagasse;

[0037] (2) Get 40kg of sargassum powder and 5kg of thiourea into an ultrasonic mixer, then add 100kg of water to ultrasonically react for 20min at an ultrasonic frequency of 50kHz, place the reacted paste in an oven at 100°C for heating and drying for 1h, and obtain Modified sage algae powder;

[0038] (3) Add the above-mentioned modified bagasse and modified sargassum powder to the agitator, add 5 kg of cerium sulfate solution and 10 kg of starch, then add water and adjust it into a paste, put the paste into a microwave heating device, and put it into a microwave heating device at a power of ...

Embodiment 3

[0040] A method for preparing lead ion adsorbent, the specific operation steps are as follows:

[0041] (1) Crush 100kg of bagasse to 60 mesh, add 5mol / L sodium hydroxide solution to soak for 4 hours, then wash the bagasse with water until neutral to obtain bagasse cellulose; add 10kg of acrylic acid horseradish to the bagasse cellulose To the anhydride copolymer, add 150kg of water, mix evenly, and dry at a temperature of 70°C for 3 hours to obtain modified bagasse;

[0042] (2) Take 60 kg of sargassum powder and 10 kg of thiourea and add them to an ultrasonic stirrer, then add 100 kg of water and conduct an ultrasonic reaction at an ultrasonic frequency of 60 kHz for 15 minutes, and place the reacted paste in an oven at 90° C. to heat and dry for 1.5 hours. Obtain modified sargassum powder;

[0043] (3) Add the above-mentioned modified bagasse and modified sargassum powder to the agitator, add 3 kg of cerium sulfate solution and 15 kg of starch, then add water and adjust it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com