Surface corrosion-resistant lithium battery flexible package film

A technology for flexible packaging films and lithium batteries, which is applied to battery pack components, battery boxes/covers, battery box/cover materials, etc., which can solve the problems of content leakage, easy corrosion, explosion, etc., and achieve good heat resistance And chemical corrosion resistance, high barrier performance, the effect of guaranteed barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

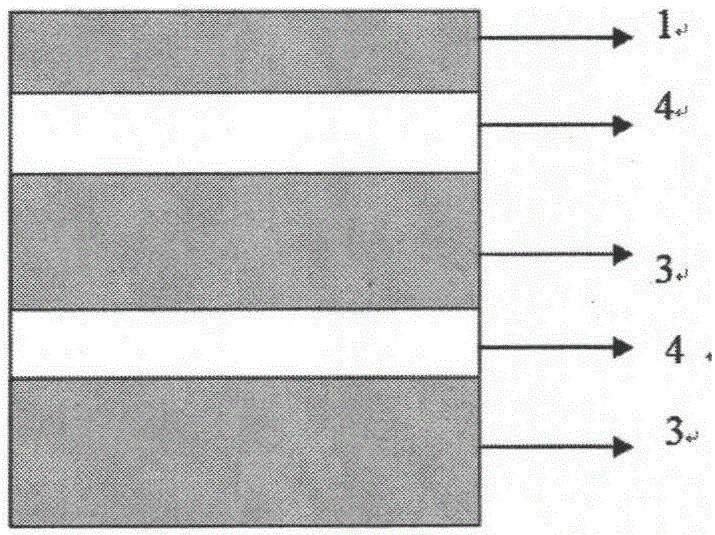

[0021] Such as figure 1 As shown, it is a schematic diagram of a lithium battery flexible packaging film with a corrosion-resistant surface. The flexible packaging film for a lithium battery with a corrosion-resistant surface includes a fluoroplastic layer 1, an aluminum foil barrier layer 2 and a polypropylene heat-sealing layer 3. The fluoroplastic layer 1 It is arranged on the outer side of the aluminum foil barrier layer 2 , and the polypropylene heat-sealing layer 3 is arranged on the inner side of the aluminum foil barrier layer 2 , and the fluoroplastic layer 1 and the aluminum foil barrier layer 2 are bonded by an adhesive 4 . The aluminum foil barrier layer 2 and the polypropylene heat-sealing layer 3 are bonded by an adhesive 4 .

[0022] Described fluoroplastic layer 1 selects the polychlorotrifluoroethylene (PCTFE) film that the thickness of Honeywell is 19 microns for use, and aluminum foil barrier layer 2 selects the 45 micron thick alloy model of Japan Toyo Alum...

Embodiment 2

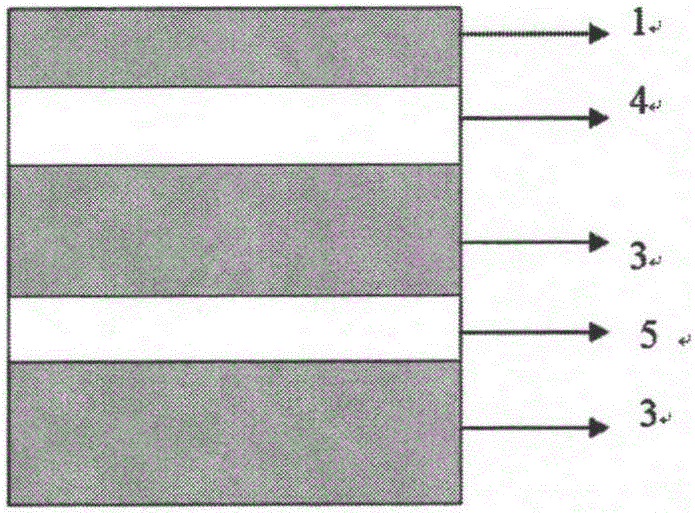

[0030] Such as figure 2 As shown, it is a schematic diagram of a lithium battery flexible packaging film with a corrosion-resistant surface. The flexible packaging film for a lithium battery with a corrosion-resistant surface includes a fluoroplastic layer 1, an aluminum foil barrier layer 2 and a polypropylene heat-sealing layer 3. The fluoroplastic layer 1 It is arranged on the outer side of the aluminum foil barrier layer 2 , and the polypropylene heat-sealing layer 3 is arranged on the inner side of the aluminum foil barrier layer 2 , and the fluoroplastic layer 1 and the aluminum foil barrier layer 2 are bonded by an adhesive 4 . An extruded polypropylene layer 5 is arranged between the aluminum foil barrier layer 2 and the polypropylene heat-sealing layer 3 , and the aluminum foil barrier layer 2 and the polypropylene heat-sealing layer 3 are composited together through the extruded polypropylene layer 5 .

[0031] Fluoroplastic layer 1 uses Honeywell polychlorotrifluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com