Method and device for cavitation-erosion accumulation processing

A processing method and technology of processing devices, which are applied in the fields of machinery manufacturing, material forming, and material removal manufacturing and processing, to achieve the effects of high potential value, low cost and little environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

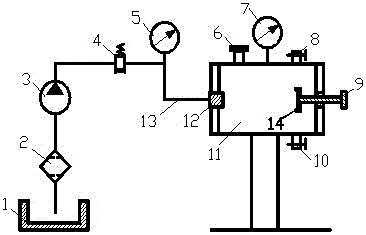

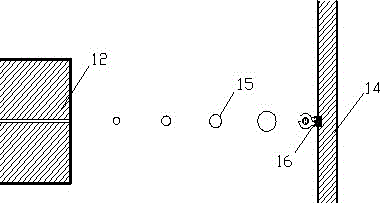

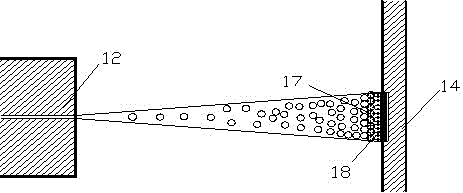

[0036] Embodiment 1: The material of the workpiece 14 used in this embodiment is ordinary steel with hardness HB=200, and the cavitation accumulation thickness H=5mm, diameter D 1 =10mm through hole processing, which includes the following steps:

[0037](1) Start the high-pressure pump set and run it for 10 minutes without load, and all indicators are normal;

[0038] (2) Control the pressure regulating valve, and wait for the pressure gauge 5 to rise slowly to 150MPa for 30 minutes, indicating that the high-pressure pump unit is operating normally, the system has no obvious leakage, the pressure is stable, and meets the implementation requirements;

[0039] (3) Fill the high-pressure vessel 11 with water and the height d from the water surface to the upper edge of the cavitation nozzle 12 1 =180mm, and pressurized so that the pressure p in the high pressure vessel 11 1 =1.0MPa;

[0040] (4) Turn on the power switch, and the water in the pool 1 is sent to the filter 2 thro...

Embodiment 2

[0047] Embodiment 2: The material of the workpiece 14 used in this embodiment is ordinary steel with hardness HB=200, and the cavitation accumulation thickness H=5mm, diameter D 1 =10mm through hole processing, which includes the following steps:

[0048] (1) The through-hole mask 19 and the workpiece 14 are laminated by pressing the sheet, and fixed on the workpiece clamping device 9;

[0049] (2) Start the high-pressure pump set and run it without load for 10 minutes, and all indicators are normal;

[0050] (3) Control the pressure regulating valve, and wait for the pressure gauge 5 to rise slowly to 150MPa for 30 minutes, indicating that the high-pressure pump unit is operating normally, the system has no obvious leakage, the pressure is stable, and meets the implementation requirements;

[0051] (4) Fill the high-pressure vessel 11 with water and the height d from the water surface to the upper edge of the cavitation nozzle 12 1 =180mm, and pressurized so that the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com