Submerged arc stud welding method for embedded part of nuclear power plant

A welding method and technology of embedded parts, applied in arc welding equipment, welding medium, welding accessories, etc., can solve the problems of easy deformation of heat input steel plate, low welding efficiency, uneven welding bead transition, etc., and achieve excellent mechanical properties, Improve welding efficiency, smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention relates to a submerged arc stud welding method for embedded parts of a nuclear power plant. The steel plate of the embedded part to be welded is Q390B with a thickness of 20 mm, the steel bar of the embedded part to be welded is HRB400E with a diameter of 20 mm, and the length of the steel bar is 700 mm. The basicity of the flux used is 1.0, and the chemical composition and weight percentage of the flux are: SiO 2 +TiO 2 : 31.3%, MnO+Al 2 o 3 : 31.5%, CaO+MgO: 26.5%, CaF 2 +FeO: 10.0%, S: 0.030%, P: 0.032%.

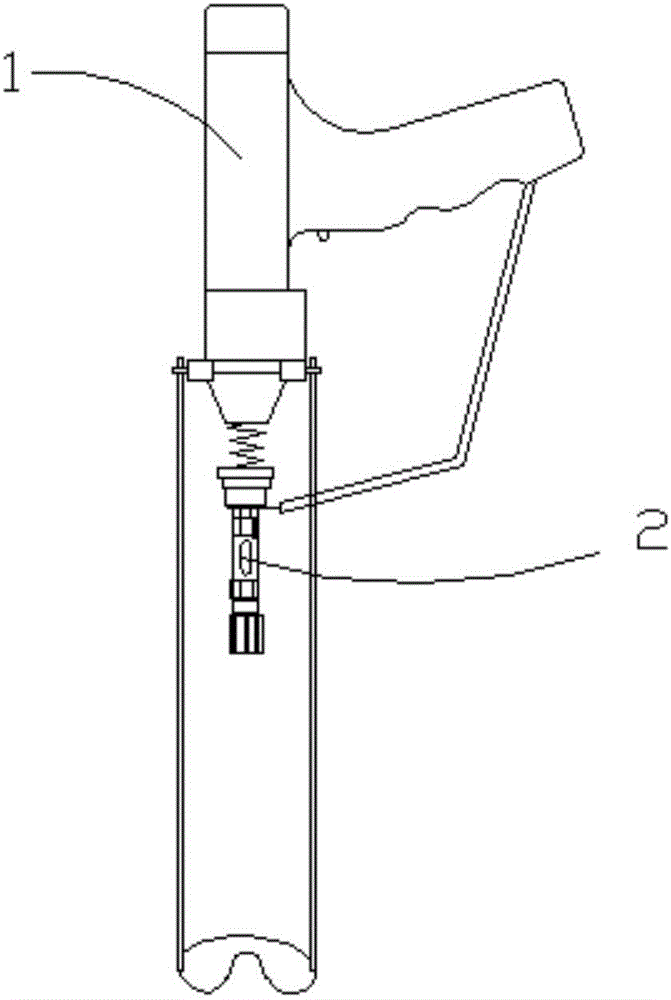

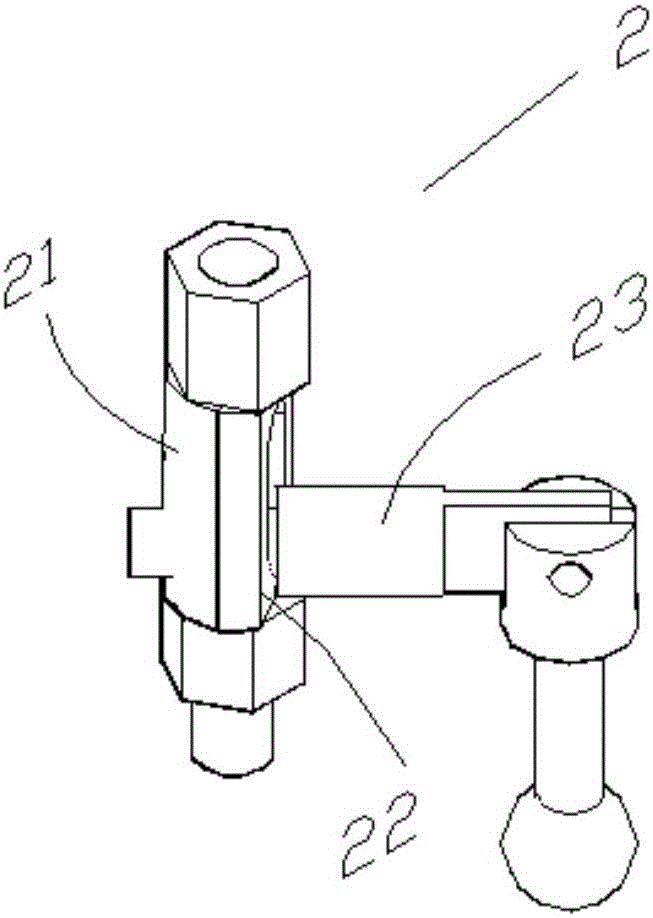

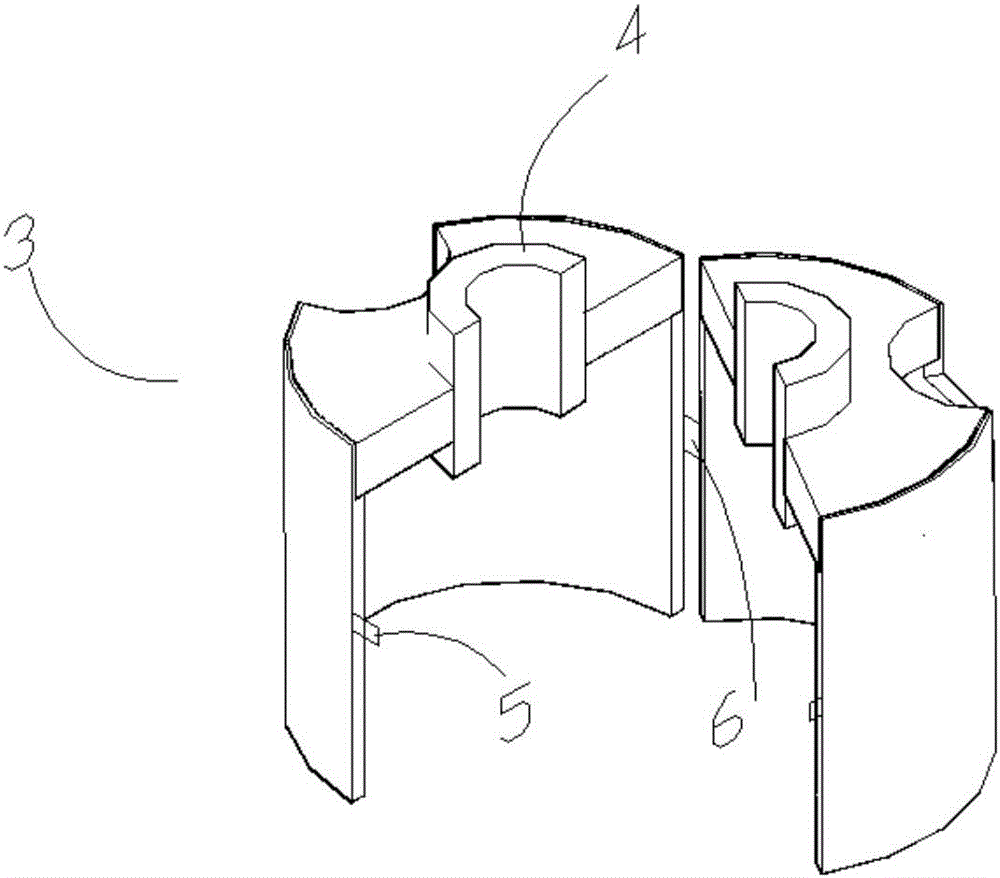

[0040] Such as Figure 1 to Figure 3 As shown, the embodiment uses a steel bar height adjusting device to adjust the protruding length and lifting height of the reinforcing bar. In this implementation, the protruding length and lifting height of the adjusting reinforcing bar are 10mm and 9mm respectively. The steel bar height adjustment device includes a submerged arc stud welding torch and an external adjustment box. The submerged arc st...

Embodiment 2

[0049] According to the submerged arc stud welding method of the embedded part of the nuclear power plant in this embodiment, the steel plate of the embedded part to be welded is Q390B with a thickness of 20 mm, the steel bar of the embedded part to be welded is HRB400E with a diameter of 22 mm, and the length of the steel bar is 700 mm. The flux used is the same as in Example 1.

[0050] The structure of this embodiment is the same as that of Embodiment 1, except that the protruding length and lifting height of the adjusting steel bars are respectively 11 mm and 10 mm. In the embodiment, the height of the flux box 3 is 100mm, the diameter of the steel bar insertion port 4 on the flux box 3 is 24mm, and the height of the adjustment box is 111mm.

[0051] The welding procedure of this embodiment is the same as that of Embodiment 1. In this embodiment, the total compression of the adjusting spring is 21 mm, the welding parameters are: welding time is 5.5 s, the current polarity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com