Equipment for recovering oil mist and organic solvent contained in industrial waste gas, and method for recovering oil mist and organic solvent using the same

A technology for organic solvents and recovery devices, applied in the direction of separation methods, portable electrostatic devices, chemical instruments and methods, etc., can solve the problems of short replacement cycle of activated carbon, reduce the adsorption effect of organic solvents, etc., and achieve the effect of preventing thermal deformation and fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

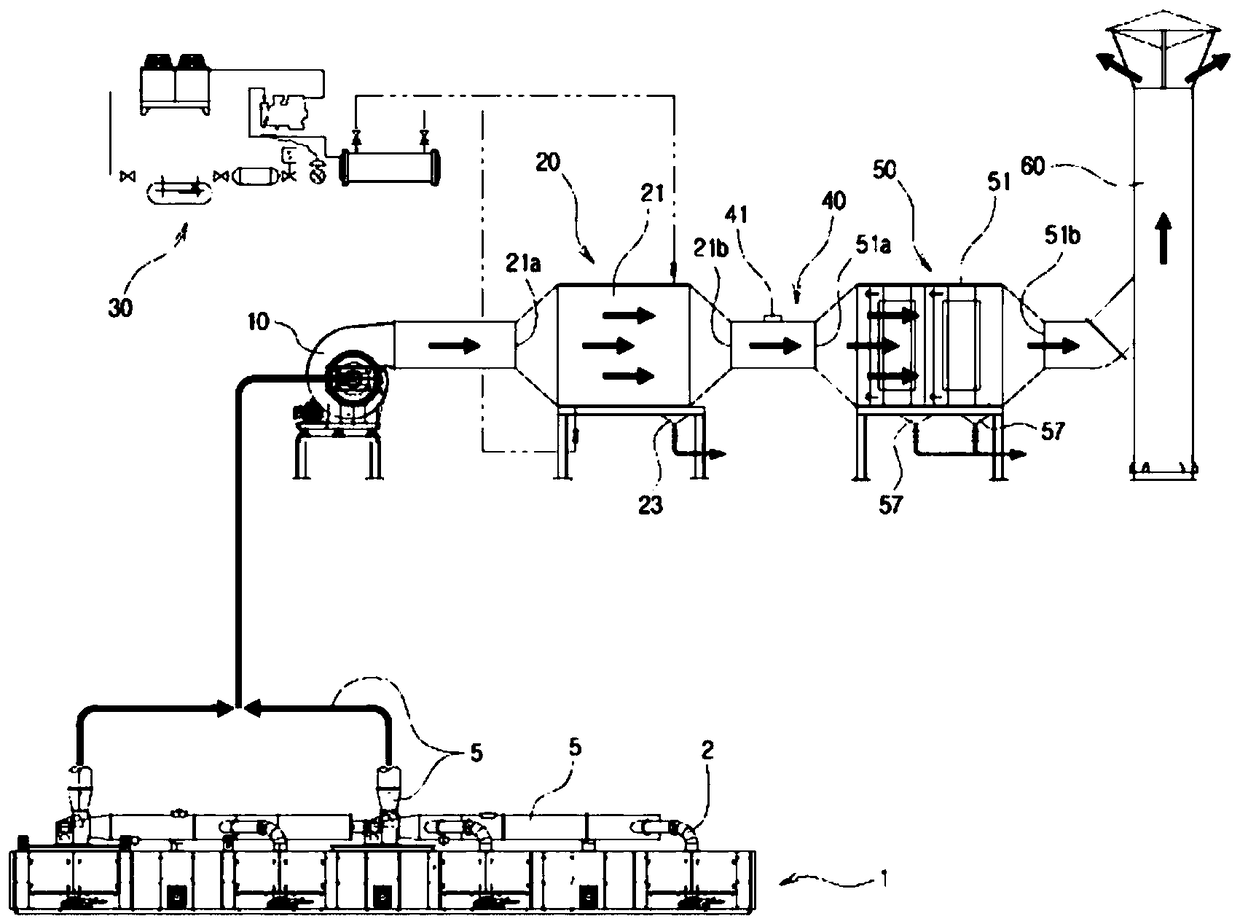

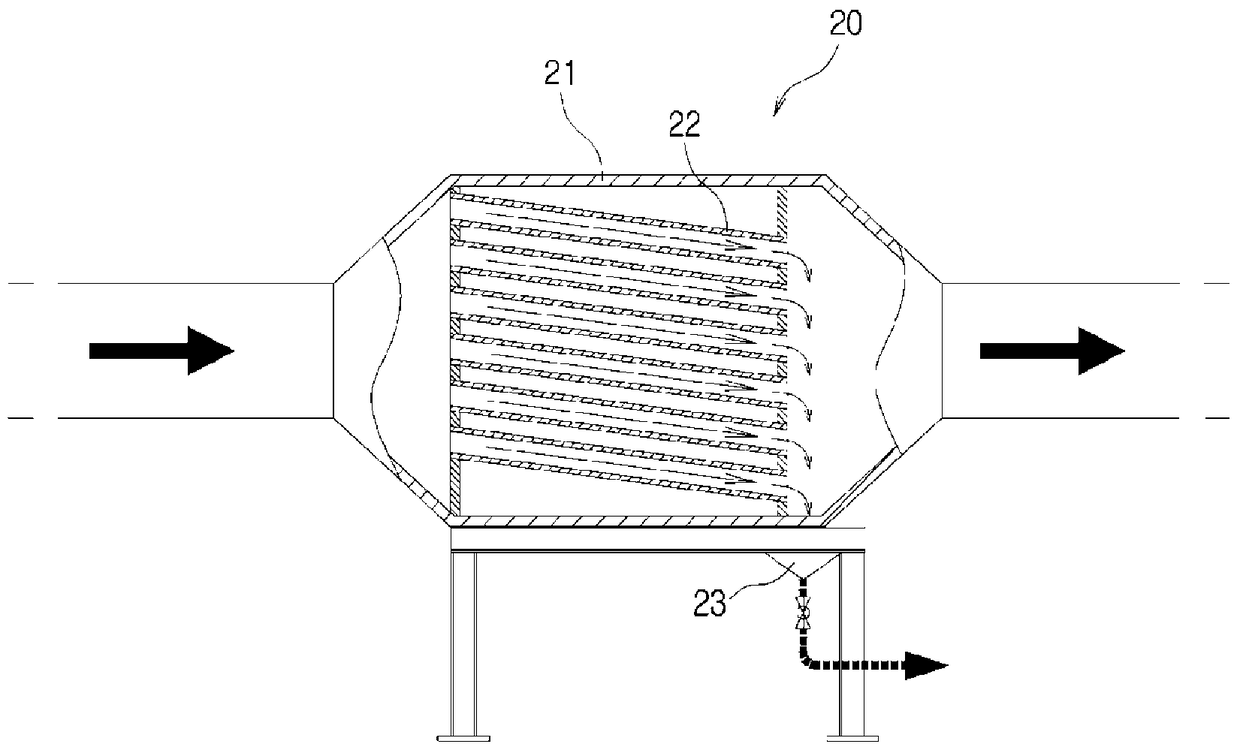

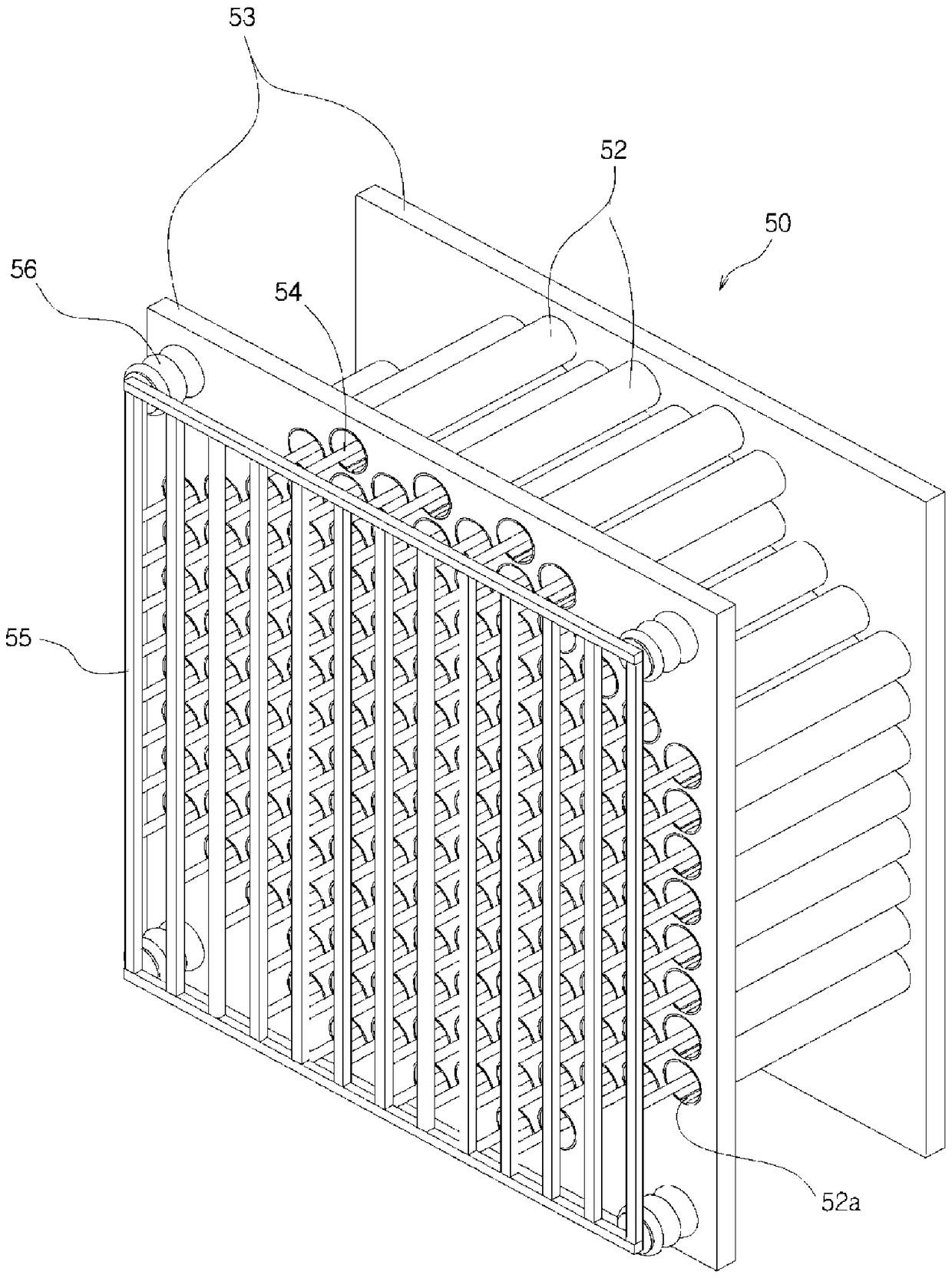

[0032] Hereinafter, details for implementing the present invention will be described in more detail with reference to the drawings.

[0033] refer to Figure 1 to Figure 7 , the oil mist contained in the industrial waste gas according to the present invention, the organic solvent recovery device, comprising: air blower (10), heat exchanger (20), cooling water supply equipment (30), moving pipe (40), electric precipitator (50), discharge pipe (60), thus, recycling is collected in industrial equipment (1 ) and organic solvents such as oil mist and VOCs contained in the exhaust gas moving to the conveying pipe (5) in the dust collecting hood (2) set in ).

[0034] Such as figure 1 As shown, the blower (10) is connected to the delivery pipe (5), so that the exhaust gas collected by the dust collection hood (2) arranged on the industrial equipment (1) and moved to the delivery pipe (5) is moved again by high pressure.

[0035]Also, preferably, the blower (10) is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com