Black phosphorus-red phosphorus heterostructure material, as well as preparation method and application thereof

A heterostructure, red phosphorus technology, applied in the field of photocatalytic materials, can solve the problem of low photocatalytic activity of non-metallic photocatalytic materials, achieve excellent visible light catalytic degradation performance, promote separation and transfer, and facilitate industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] And, a method for preparing a black phosphorus-red phosphorus heterostructure material, comprising the following steps:

[0027] S01. According to the mass volume ratio of amorphous red phosphorus and deionized water (1-2) g: (10-15) ml, weigh amorphous red phosphorus and add it to deionized water, and stir to form a uniform suspension;

[0028] S02. above-mentioned suspension is transferred in the autoclave and sealed;

[0029] S03. Reacting the suspension in the autoclave at 180-200° C. for 10-48 hours, washing, and vacuum-drying the obtained material to obtain a purified amorphous red phosphorus material;

[0030] S04. adding the purified amorphous red phosphorus material into an agate ball mill jar, and filling the ball mill jar with argon gas of 1 atmosphere to seal;

[0031] S05. The ball mill jar is placed on a ball mill, the reaction speed of the ball mill is 400-600 rpm, and the milling time is 0.5-18 hours, to obtain the black phosphorus-red phosphorus hetero...

Embodiment 1

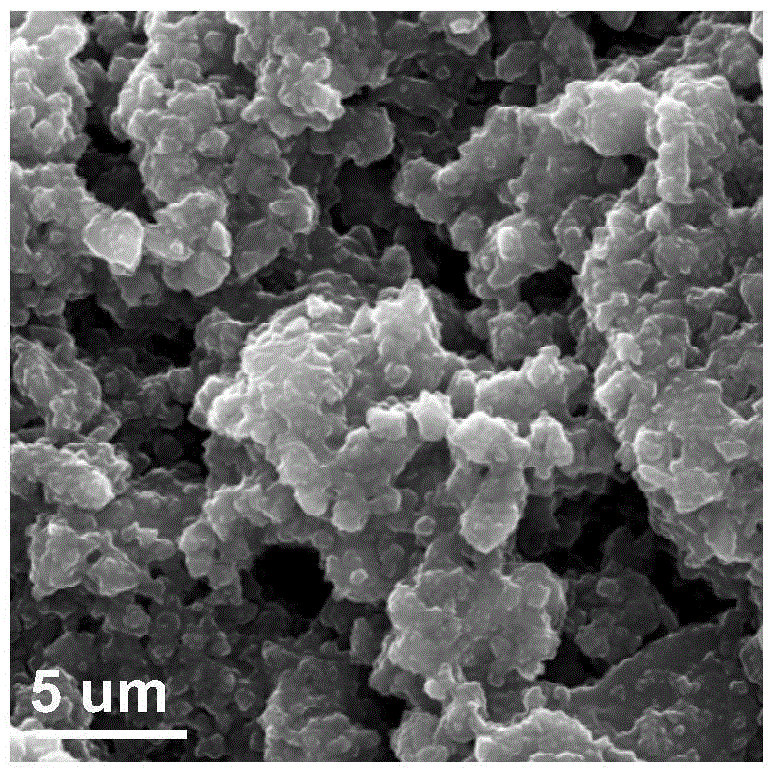

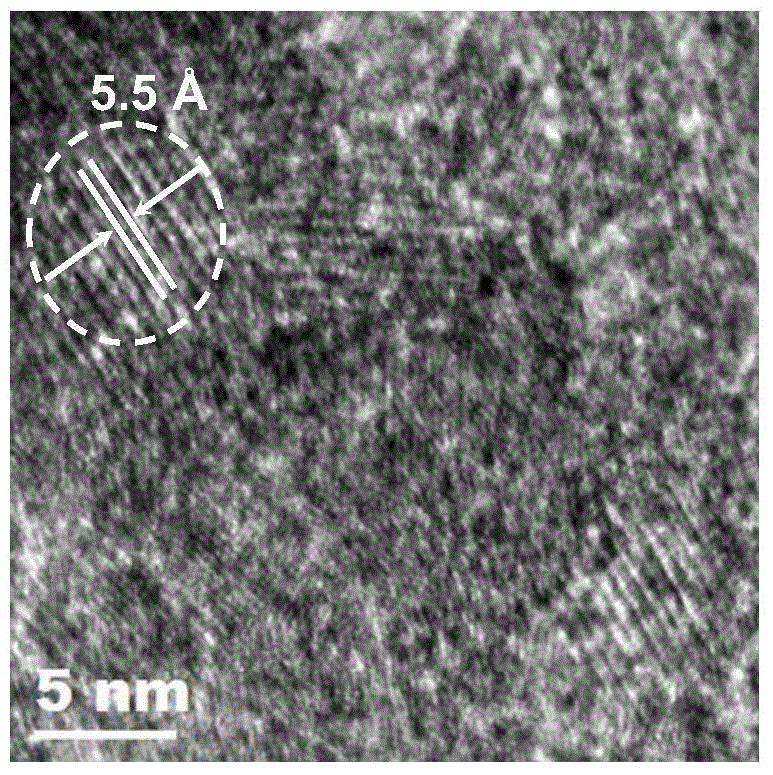

[0039] Add 2 g of commercial red phosphorus into 15 mL of deionized water and stir evenly, then transfer it into a 25 mL autoclave and seal it. React at 200°C for 12 hours. The obtained purified red phosphorus is separated and washed, dried in vacuum and used for later use. Take 1.6 g of the above-mentioned purified red phosphorus and add it to a 50 mL agate ball mill jar, and add agate balls with a mass ratio of 20:1. Introduce 1 atmosphere of argon to seal. Ball mill for 2 hours at 450 rpm. The obtained material is black phosphorus-red phosphorus heterostructure material. figure 1 It is a scanning electron microscope image of the black phosphorus-red phosphorus heterostructure material obtained in Example 1, showing that the particle size of the obtained material is 1 to 2 microns; figure 2 The X-ray diffraction analysis spectrum of the black phosphorus-red phosphorus heterostructure material obtained in Example 1 shows that the obtained material is a mixed phase of bla...

Embodiment 2

[0041] The ball milling conditions were changed, the ball milling speed was 450 rpm, the ball milling time was changed from 2 hours to 18 hours, and other experimental parameters were the same as in Example 1, so that black phosphorus-red phosphorus heterostructure material particles (average diameter 0.5 microns) could be obtained. Figure 4 It is the scanning electron micrograph of the black phosphorus-red phosphorus heterostructure material prepared in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com