Preparation method of hydrophilic copolymer coated nano-oxide modified hollow fiber membrane

A hydrophilic copolymer and nano-oxide technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc. Good, high mechanical strength, the effect of alleviating agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

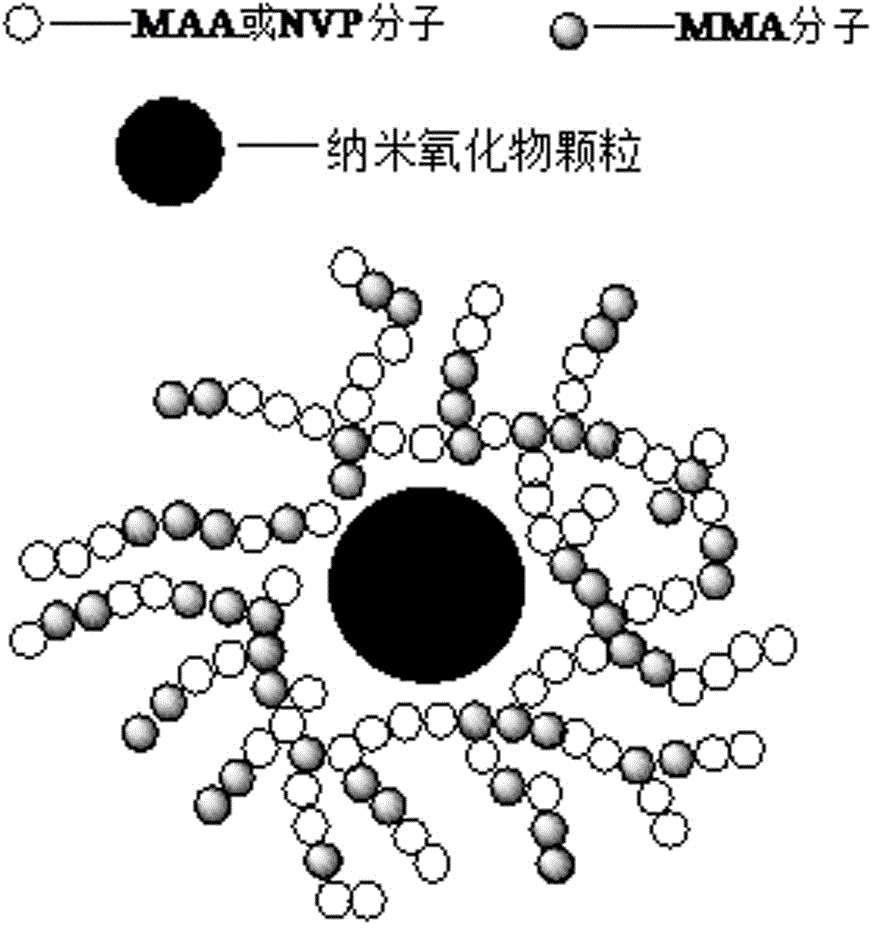

[0022] (1) P(MMA-co-MAA)@SiO 2 Composite preparation: first add 3wt% nano-SiO to the glass container sequentially 2 , 97wt% solvent DMAc. Finally, put the glass container into an ultrasonic cleaning tank, control the temperature at 60°C, and ultrasonicate for 45 minutes to make the SiO 2 Disperse evenly. Add the dispersed solution to the reactor, add the reaction monomers MMA and MAA, the total monomer content is 30wt%, the mass ratio of MMA to MAA is 5:5, and then add the initiator azobis Isobutyronitrile was stirred with nitrogen gas for 30 minutes, and the air in the reaction kettle was discharged. Under the protection of nitrogen, react for 24h, and the reaction temperature is 65°C. After the reaction, the system was a pale yellow transparent viscous emulsion. The emulsion was purified by dialysis with pure water in a dialysis bag for 24 hours to replace the solvent and soluble small molecule polymer. After dialysis, the liquid was dried in a vacuum oven at 60°C for la...

Embodiment 2

[0032] (1) P(MMA-co-NVP)@SiO 2 Composite preparation: first add 3wt% nano-SiO to the glass container sequentially 2 , 97wt% solvent NMP. Finally, put the glass container into an ultrasonic cleaning tank, control the temperature at 60°C, and ultrasonicate for 30 minutes to make the SiO 2 Disperse evenly. Add the dispersed solution to the reactor, add the reaction monomers MMA and NVP, the total monomer content is 30wt%, the mass ratio of MMA to NVP is 4:6, and then add the initiator azobisiso Heptanitril was stirred with nitrogen gas for 30 minutes, and the air in the reaction kettle was discharged. Under the protection of nitrogen, react for 24h, and the reaction temperature is 65°C. After the reaction, the system was a pale yellow transparent viscous emulsion. The emulsion was purified by dialysis with pure water in a dialysis bag for 24 hours to replace the solvent and soluble small molecule polymer. After dialysis, the liquid was dried in a vacuum oven at 60°C for later...

Embodiment 3

[0038] (1) Complex P(MMA-co-MAA)@TiO 2 Preparation: first add 2.5wt% nano-TiO to the glass container sequentially 2 , 96.5 wt% solvent DMAc. Finally, put the glass container into an ultrasonic cleaning tank, control the temperature at 60°C, and ultrasonicate for 60 minutes to make the TiO 2 Disperse evenly. Add the dispersed solution to the reactor, add the reaction monomers MMA and MAA, the total monomer content is 40wt%, the mass ratio of MMA to MAA is 3:7, and then add the initiator azobis Isobutyronitrile was stirred with nitrogen gas for 30 minutes, and the air in the reaction kettle was discharged. Under the protection of nitrogen, react for 8h, and the reaction temperature is 70°C. After the reaction, the system was a transparent and viscous emulsion. The emulsion was purified by dialysis for 24 hours with pure water in a dialysis bag to replace the solvent and soluble small molecule polymer. After dialysis, the liquid was dried in a vacuum oven at 60°C for later us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com