Aluminum-alloy disc type thrust motor clamp joint seawater processing device

A technology of a clamp joint and a processing device, which is applied in the field of seawater treatment device of a clamp joint of an aluminum alloy disc thrust motor, can solve the problems of high maintenance rate and influence on production cost, and achieves improved service life, compact structure and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

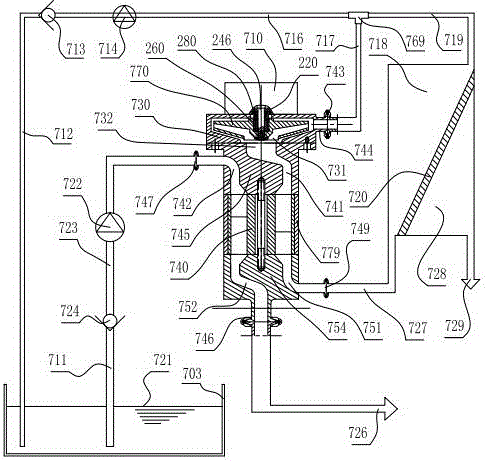

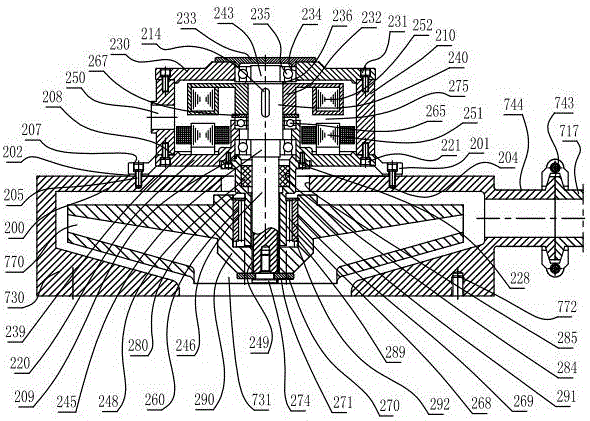

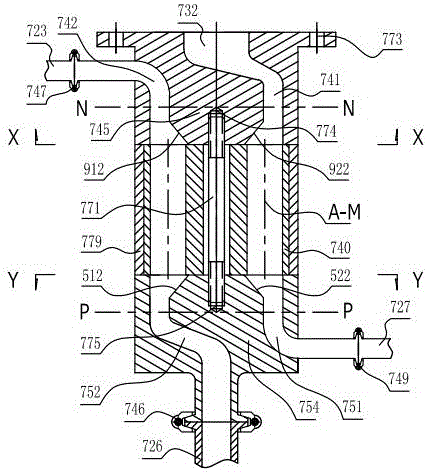

[0063] The structure and working principle of the present invention and the application in the reverse osmosis seawater desalination system are further elaborated in conjunction with the accompanying drawings and embodiments:

[0064] Figure 30 , a schematic diagram of the assembly of two sets of lower bolt and nut sets 144 assembled in pairs, the right half tile 141 of the lower clamp and the left half tile 142 of the lower clamp.

[0065] Figure 31 , a schematic diagram of the assembly of two sets of upper bolt and nut sets 166 assembled in pairs, the right half tile 161 of the upper clamp and the left half tile 162 of the upper clamp.

[0066] Figure 36 , the end view of the lower half tile 641 of the horizontal inlet clamp and the upper half tile 642 of the horizontal inlet clamp fastened by two sets of horizontal clamp inlet bolts and nuts 677 assembled in pairs.

[0067] Figure 37 , an end view of the horizontal clamp lower half tile 671 and the horizontal clamp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com